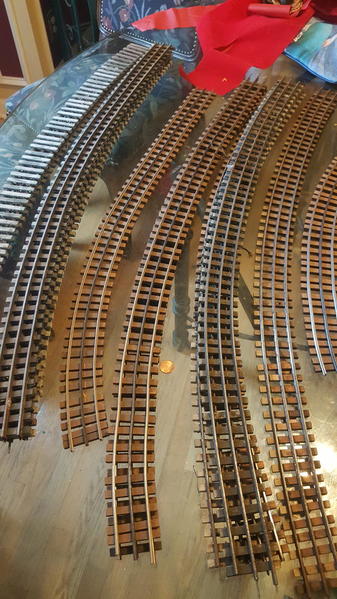

all of my layouts have been with FastTrack so kind of lost when it comes to gargraves track. well yesterday on the local craigslist I found a older gentleman selling a lot of gargraves track in talking to him it seems the track is about 30 years old. needs cleaned but not to bad. he stated it stainless track with wood ties and he said it can be bent and even has a few pieces that are pre bent couldn't tell you the radius as the pieces are 36 inch's long and not a very tight curve I would guess in the 108 range o72 next to it looks tight .

first I got 49 36 inch long pieces and 21 curved pieces 36 inch's long for $150.00 figured it was a good deal. since it's stainless might want to do a outside o scale layout in the front flower bed raised above the ground so the wood ties are not touching the ground I know wood ties = no good for outside. for $150. not concerned about if a few ties rot over the next few years . anyways how do you tell if it's able to be bent (flex track) or can all gargraves track be bent just some is easier than others. next cleaning it I was thinking of a scotch bright pad to clean them up sound good? thirdly pins some of the track has pins some doesn't it looks like brass wire is that correct ?