Ok, lets get our terminology correct first. I have worked for 25 years in the cement and construction materials industry, so let me explain something here.

This post has, so far, talked about 3 related, but totally differedn types of facilities.

1. Cement plant: Cement is the powder that makes redi mix concrete set up hard. Cement is manufactured in a "cement plant", by burning limestone in a kiln, along with a few other ingredients. After being burned in the liln, the mix becomes 'clinker". Clinker is kind of like large rocks and rubble, and, is not reactive when stored out in the weather/rain. The cement plant grinds the clinker into a fine powder, sometimes with a few additives, and this dry powder is then called Portland Cement. A cement plant is a very large facility the usually has a limestone mine adjacent to it.

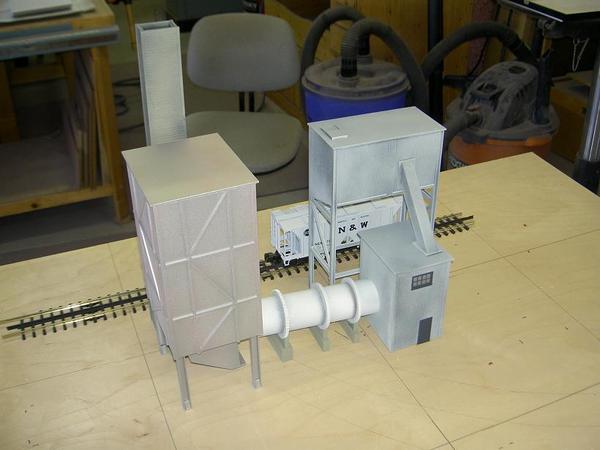

2. Cement distribution facility: PRB did a brass model of the Tilbury Cement facility. This is a "cement distribution facility", where cement was brought in by rail, stored, then shipped out by truck. It received bagged cement in boxcars, and bulk cement in covered hoppers.

3. Redi mix concrete plant: This is a plant the takes powdered cement, sand, and gravel, and mixes it all with water to make redi mix "concrete". Some plants mix it onsite, then load it into the mixer trucks for delivery. Other plants dump the dry ingrediants and water into the mixer trucks, and the trucks do the mixing.

I am a friend of John's, and used to model with him, and work for him now and then, at PRB. I don't think he has any of those plants left. They are really a beautiful model. You can email him and see if he might still have one, but I doubt it.

His email is john@pecosriverbrass.com

I have one of those Tilbury plants in the original shipping box, and have thought about selling it. Just do not have room to use it right now. But not sure, as I could never replace it if I wanted one in the future.

There was a plan published for the Tilbury plant in a Model Railroader mag. many years ago. Also, MR or RMC published plans for a redi mix concrete plant. I have both in my files. If I can find them, I will post here later, what issues those two plans appear in.

Jeff