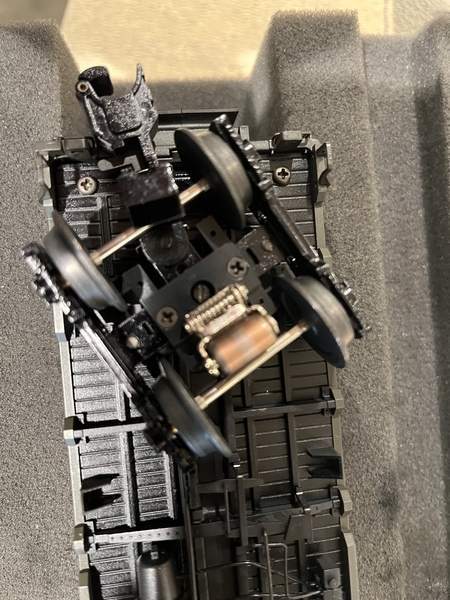

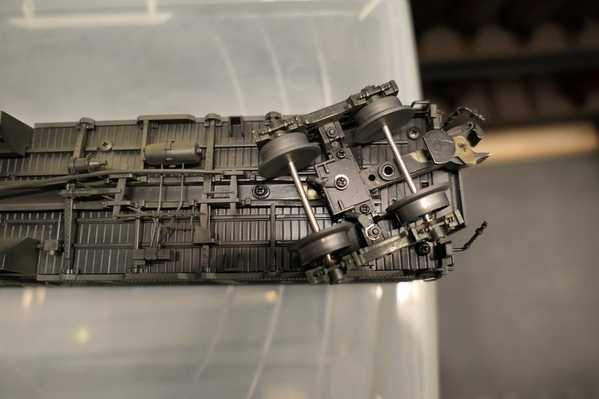

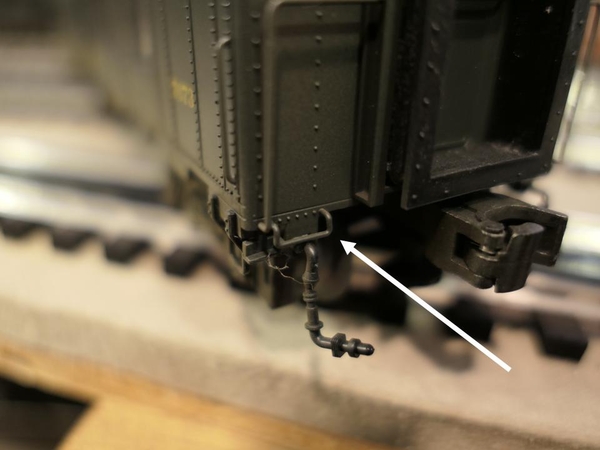

Can someone take a picture of the underside of an Atlas troop sleeper car with the trucks rotated to the side? I want to modify one to add steps at the end corners but they might foul the turning of the trucks, and the model I own only has the 2R trucks which might not have the same clearances as 3R trucks.

Thanks.