Crappy first attempt video added at bottom).

I'm far from being a pro decoder installer. (Add taking and posting videos to that) Just a beginner installing my 3rd DCC decoder and learning as I go. But, I had some email requests to repost this topic so here goes. Hopefully this will show what an average guy can do and encourage others to do DCC installations in our fleets of brass DC engines.

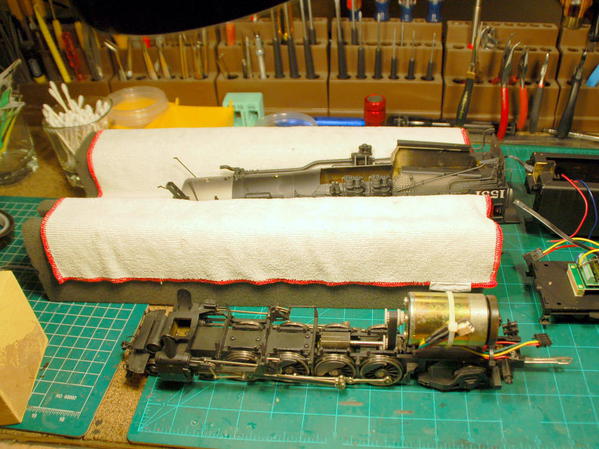

Pictures just before final assembly. Stay tuned for updates if interested.

This is a Sunset DRGW 4-8-2 Mountain Locomotive in which I'm installing a QSI Titan Q3 ET decoder. QSI Superbass speakers in tender and boiler. All LED lighting. Stripped out all the stock wiring and started over. The tender shell will be the speaker enclosure and will be sealed off as is usual. The smaller speaker in the boiler is in an enclosure and is attached to the boiler weight.

This is the same general configuration I used for my Sunset UP 844 FEF-3 with pretty good results but different speakers. With the QSI Titan the individual sounds can be balanced or shifted between the tender and boiler speaker(s). In UP 844 the big bass response is from the tender. When shifted to the boiler for more realistic positioning the bass response is much less -- as expected. But, using the boiler speaker to at least shift the sounds forward somewhat and get a bigger sound helps. The ideal is of course two speakers in the boiler as some are doing. But, from three feet away what I've done is acceptable to me anyhow. A trade-off. Good bass but coming mostly from the tender.

At the risk of going on the defensive, I will tidy up the wiring as part of final assembly. The big clunky tether/connector routes motor and track power between engine and tender. With a six amp decoder I decided to err on the conservative side. The second Micronics 1 amp connector in the Mountain is for lights. I gotta believe that I can find a smaller power routing tether that will still meet the amperage requirements of track and motor power. But this worked out okay on the UP 844. The connector partially nests into the expanded opening in the tender shell when in operation.

Perhaps some of you have a power tether recommendation and speakers for boiler recommendations? Lots to learn.

The tender bottom view shows the Reed Switch that can be used in DC or DCC operation to reset the decoder with a magnet. The diagram is my hen scratched working copy. When the engine is operational will redo it for my "permanent" documentation.