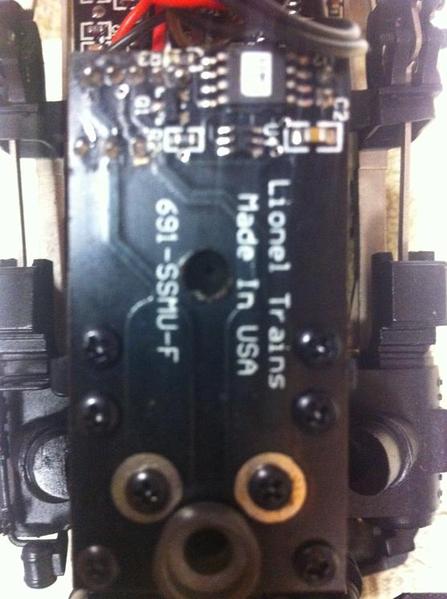

Hi guys- I did the cam lobe conversion 5-6 years ago. Since the early scale Berkshire and the scale GS-2 didn't have a tach tape and reader on the flywheels, I suspected they'd have a micro switch and a cam to trigger the smoke unit fan and chuff. I did the Berkshire first, removed the boiler shell and determined that the cam was under one of the large pc boards on the second driver axle. I took a photo of the wiring/plugs before unscrewing and lifting off the pcb. Once the pc board was off, the cam was exposed . I used Q-tips and pipe cleaners with ScaleCoat thinner, and also denatured alcohol, to remove all oil and grease from the cam. I roughed up the 2 hollows in the cam that are between the cast-in lobes, then mixed some Quick JB Weld and installed the goop into one cam hollow at a time with a toothpick, carefully shaping the JB Weld into a lobe. After the JBW hardened, I trimmed the new lobes with a very sharp hobby knife so each looked like a bell curve (best description I can make) and rotated the mechanism by turning the flywheel so the cam rotated and contacted the micro switch, making the switch's contacts close. You have to be very precise to get the JBW lobes exactly opposite each other and the same distance from the cast cam lobes so the chuff is even at 6, 9, 12, and 3 o'clock on the side rods. The peaks of the JBW lobes need to be centered in the hollows of the cast cam, with nicely sloped sides so the micro switch's contacts slide over each lobe peak smoothly. Once the job was done, I replaced the pc boards and wiring, then I ran the engines with the boiler shells off to verify that I'd made the new lobes correctly. There were no adverse effects on the smoke unit and fan pulses; fan pulsed at 4 chuffs per revolution of the drivers and as engine speed increased the fan went into the usual full blowing mode. Once everything worked, I used a bit of grease on the cam lobes. I do recommend getting rid of the woven fiberglass batting that was commonly used a few years ago. I now use part no. 691SMKP008, which is a finely stranded fiberglass rope about 1/4" diameter. This is wound into the smoke unit chamber and the heating resistor is supposed to nestle into the little hollow that results from the winding. Be sure to keep the fan air exit into the smoke chamber unobstructed.

If I'm ever to post a video I'm going to need some instruction. Thanks.