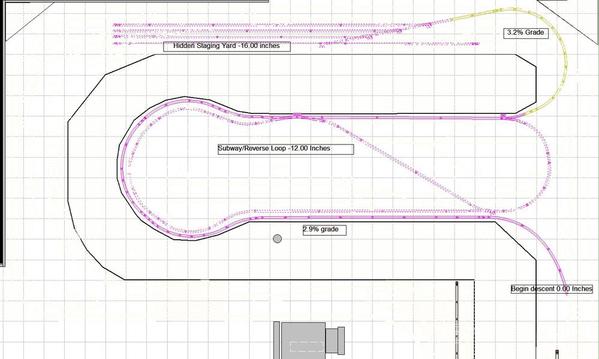

I'm planning on having a lower level "staging" yard below the main yard on my new layout, the Trenton & Western. For those who might not know, "staging" is the idea of keeping completely assembled trains, out of site until they're needed. The idea that comes from the prototypical operation world of scale model railroaders. The trains appear to come from, and pass on to, far away destinations that are not visible on the layout itself.

Having done this successfully on a previous O-gauge layout, I knew a few facts:

1. One dual can-motored diesel with traction tires can easily pull 15 average length, factory weighted, freight cars up a 4% ramp track (grade). Easily.

2. The distance between my two decks, rail head to rail head was only 12" and it was difficult to reach in there to fix or grab anything if I needed to.

On the new layout I wanted two make sure the two decks were at least 14" apart to make any necessary reaching in easier, but I simply didn't have the same amount of linear distance for the ramp track (grade) to connect the two levels. So before I built anything permanent , I built a mock up of the staging yard and the ramp track (grade) to see if I even had a chance of making this thing work. Here are the results:

1. The ramp track rises 14 inches over 17 linear of track, with is about a 7% grade

2. More than half of that 17 feet (about 8 feet) is on an 080 curve.

3. One dual can-motored diesel with traction tires can easily pull 12 MTH auto racks (a train about 19 feet long) up that 7% curved ramp track. Easily.

4. Low riding cars like scale double stacks will not bottom out if the grade is consistent and includes 12" of gradual "easement" at the top & bottom of the ramp.

5. Many of the trains I plan to store down there are double headed with two powered units so they'll be more than able to run in and out of the yard.

I'll make a video tomorrow and post it so you can see the whole thing in action.

Since we always need MORE ROOM to store or park trains on our layouts, I say go ahead and give this kind of lower level "staging" a try on your layout and see if it works for you.

- RICH