I intend to document my scratchbuilding of a New Haven rebuilt 36' double sheathed boxcar in this thread. After completing a few craftsman kits (Ambroid and Suncoast), I wanted to try scratchbuilding a prototype I had always wanted.

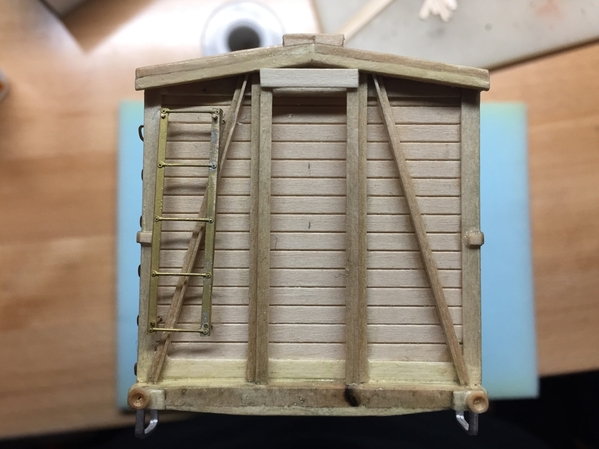

The New Haven did not own a single steel boxcar until 1941 - before then, the New Haven's boxcar fleet consisted primarily of 36' double sheathed cars built in the 1910s and rebuilt with new superstructures between 1926 and 1929. These rebuilds consisted of two groups - one with steel Dreadnaught ends and Youngstown doors, and one with steel reinforced wooden ends and wooden Camel doors. Over 12,000 cars were rebuilt. The full history of these cars is documented well in the New Haven Historical and Technical Association's 'Shoreliner' magazine, Volume 35 Issue 3, in an article written by John Nehrich and Chris Barkan. A diagram of these cars can also be found online here, under car numbers 160000-164999:

Alphabet Route - New York, New Haven, and Hartford

I want to model one of the cars with the steel Z-bar reinforced wood ends, but with a Youngstown door as some of these cars ended up in late 1930s. I purchased all the wood stock from Northeastern Scale Lumber. I calculated key dimensions from the diagram on the Alphabet Route site, as well as the Shoreliner article.

Like the Craftsman kits, I began by building a rectangular core from Northeastern's freight car floor, end sheet, and freight car inner roof pieces.

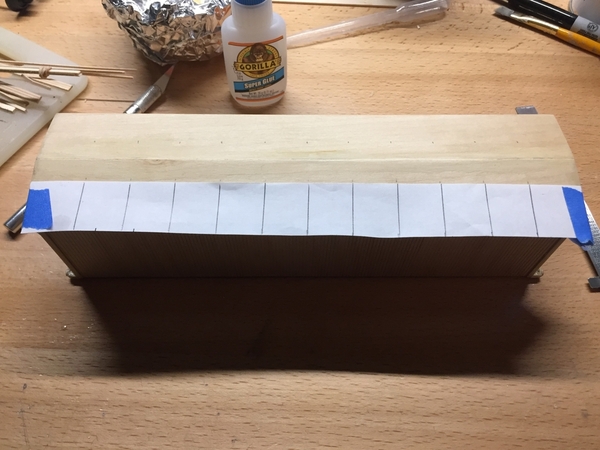

Cutting the floor and roof pieces to length:

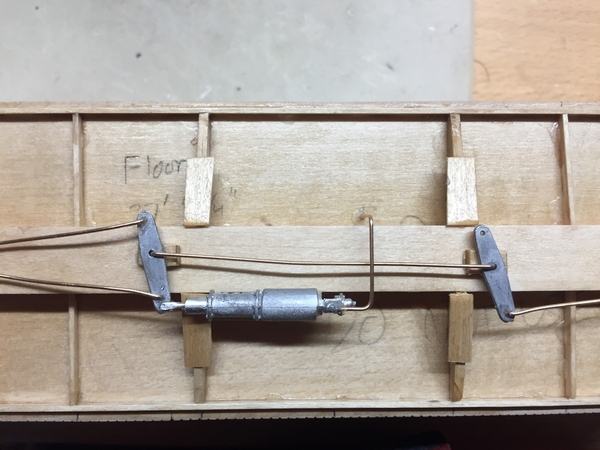

Building the frame with three pieces of end sheet, cut to the appropriate height:

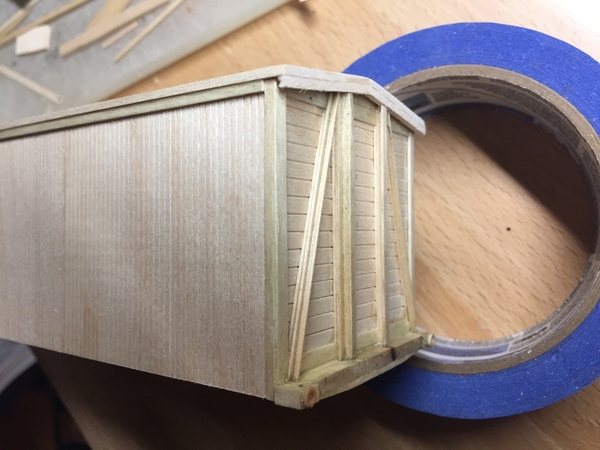

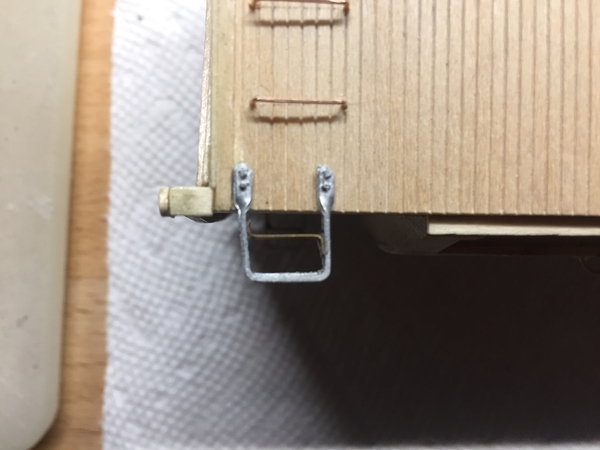

Two pieces of the wood sheathing for the ends, cut to shape and ready to be attached. Before gluing them in place I coated the small ledges of the floor at the ends with Scalecoat sanding sealer and brushed with 00 steel wool. These ledges are on the outside of the car, and will be where the steel Z-bar bracing is applied.

All I have for now.

~Chris