All,

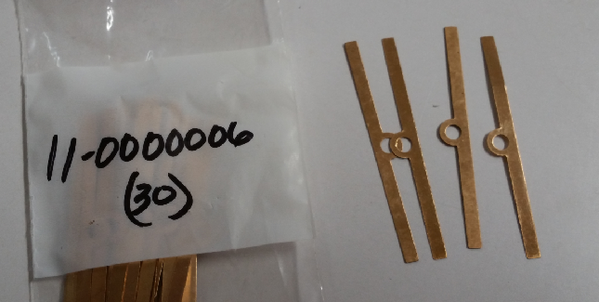

I am looking for some advise on correcting an issue I have. I have a holiday layout with an 042 loop that contains 3 Gargraves 042 switches. I ran into an issue where the grandkids Thomas engines will stall going through these switches. Some will stall in 1 direction and not the other. Some will navigate the turnout and not the straight through. I assumed it had to do with the short wheelbase and rubber tires. I am preparing to reassemble the layout and have some of the track sections mocked up to see what changes I could make to improve my issues. These small engines only have a rubber tire on 1 driving wheel. It does not appear that all the other wheels are on isolated or non-conducting sections at the same time. I double checked the center rail connectivity and everything checks out there as well.

Does anyone have any ideas?

The attachment shows an example of what I have including the way I have cut the frog side rail for anti-derailing wiring (arrows).

Tony