Yesterday evening, I watched an excellent video - featuring real steam locomotives; it was mostly old, but good, footage.

This one particular segment featured, the biggest steam locomotives, used in North America; including, Norfolk and Western and Union Pacific equipment.

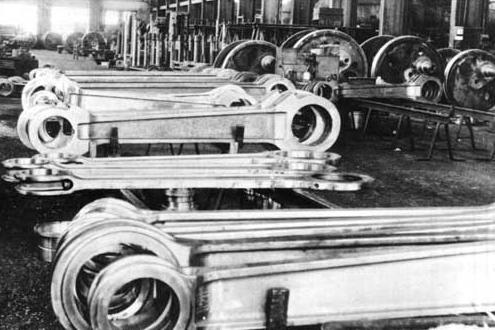

One of the things that caught my attention, was seeing the side rods etc. moving at extremely high speeds; it had an EXTREME - SOMETHINGS GOING TO BREAK look... at those speeds.

So many, fairly large, moving parts; it looked like it would be physically impossible, for those components to move any faster; and, if they were able to... something would give.

This must have required significant ongoing maintenance, to keep these massive machines... working and safe.

I think that type of steam locomotive technology, must have reached it's limit...

BTW, it's fortunate that some people went to the trouble of capturing these unique machines, in action, for future generations to enjoy/see.

Rick