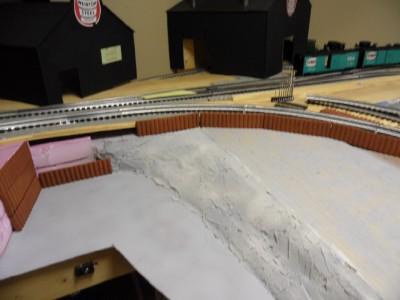

This is my version of Standard Slag in Weirton, WV. It is a work in progress.

The slag yard is part of an access hatch that will pull away from the layout.

This first photo is an overall shot of the hatch. To the left (North) is a foam "plug" that will be removed first. Then electrical harness will be disconnected. AFter that, the gray portion (slag yard) will slide left and out, allowing me to duck through the exposed benchwork to reach areas to the right.

There will be a track located at the top of the slope (extends from the switch). Slag cars will be pushed onto this track and "dump" their loads down the slope. A power shovel will operate in the widest part of the slag pit floor.

The second photo shows the steel pilings that will form the face of the "plug" as well as the eastern portion of the pit.

The third photo shows the extension of the steel pilings as they curve around to define the slag yard. These are all test fittings (nothing has been permanently mounted). I still have to put these resin castings in warm water and attempt to bend them to fit the curve.

Will post more as soon as I make some more progress.

George