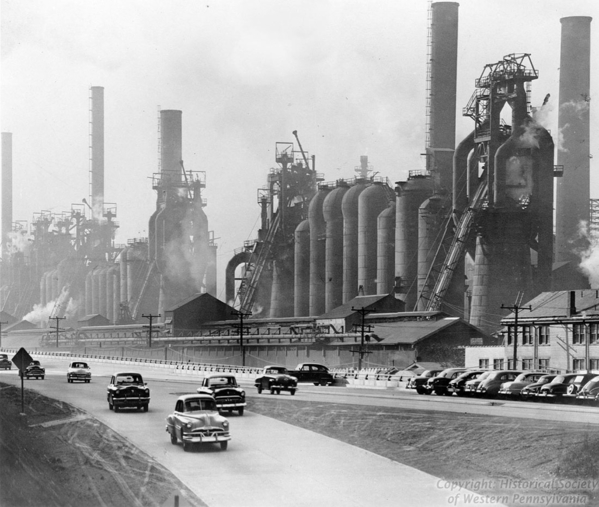

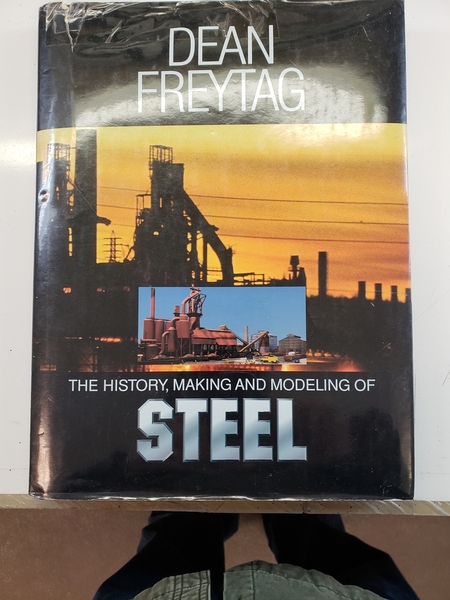

Dave's project is a very good representation of a Blast furnace. Used to take iron ore, coke, and other ingredients to pig iron, liquid iron. The rail transportation would then move the liquid iron to a BOF, Basic oxygen furnace, where a large vessel, with no external heat, would be used, with an oxygen lance/supply, to make steel. Oxygen supplied, to the liquid iron, removed carbon, at the same time, alloys were added. This is an exothermic reaction that generates it's own heat.

Today a lot of melt shop iron come from scrap metal, processed in electric arc furnaces.

Finished liquid steel (old) was placed in ingot molds to harden. Molds would then be processed via a two high roll mill after reheat/annealing.

Finished liquid steel (new) goes to a large, long, vertical building call a continuous caster. The caster takes the liquid steel and allows it to cool as one very long, curved, piece of steel. Vertical to horizontal. This piece of steel, is much more efficient, eliminating end crop waste, scaling and re-heating. Product goes directly to finish mills.

Koppel Steel, what remains of Babcock and Wilcox Steel, Beaver Falls, PA Plant, is a melt shop that has a continuous caster.

Rail service, primarily, moves scrap metal to the arc furnaces. Finish blooms, at the Koppel melt shop, are loaded on trucks, and shipped to the processing plant, Ambridge, PA.

?? A lot in addition to Dave's Blast furnace complex ?? IMO. Mike CT.