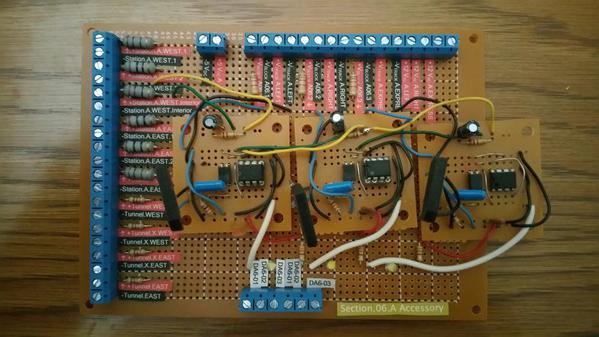

If anyone has followed my posts in the other forums you will notice that I am building a second generation modular layout for subway trains. There are 16 modules. Each of these modules will have electronics to control accessories such as block current detection, station lighting, tunnel lighting, building lights, and street lights. There is also a controller that is the brains behind signal control. Usually there is a separate circuit for the accessories and the controller for each module (section). In some cases there may be multiple circuits depending on the complexity. For one section (#5) the accessory and controller circuits are combined.

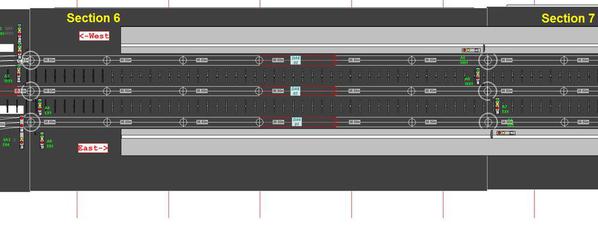

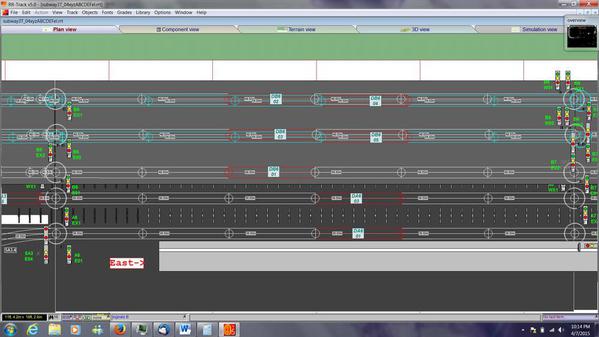

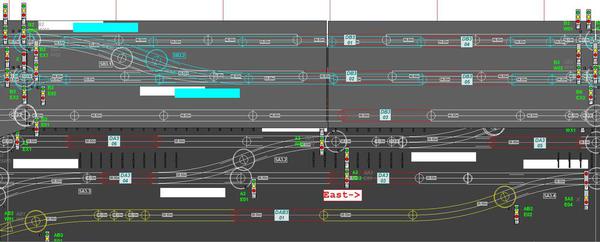

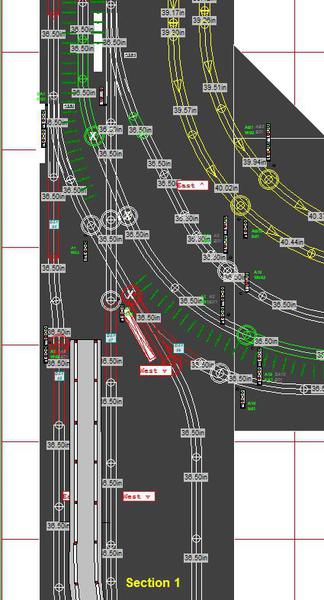

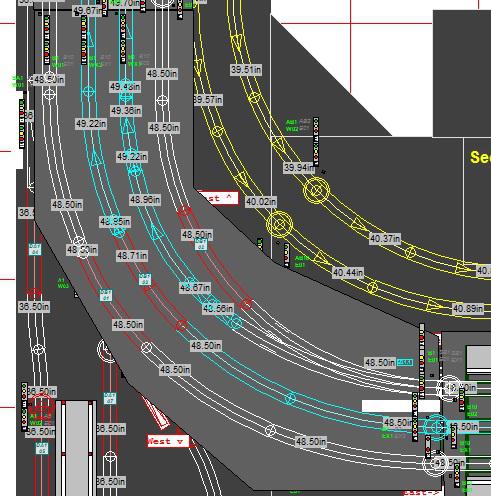

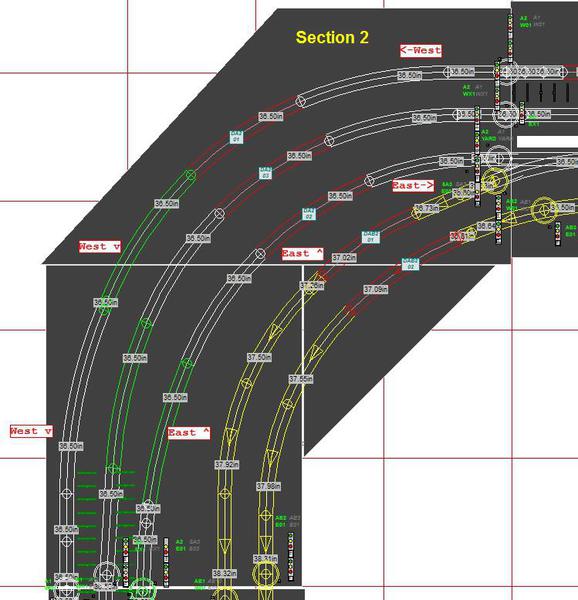

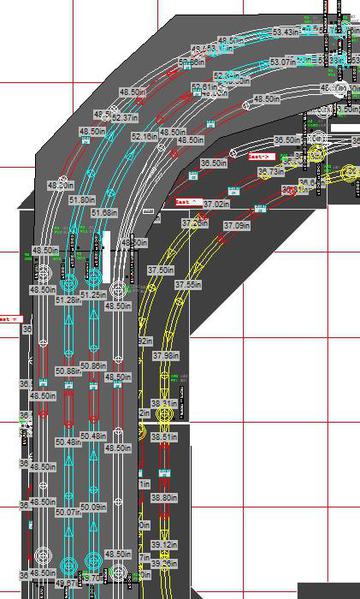

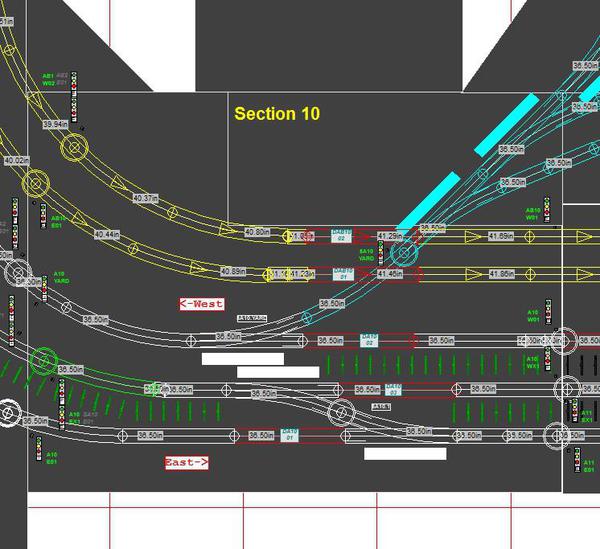

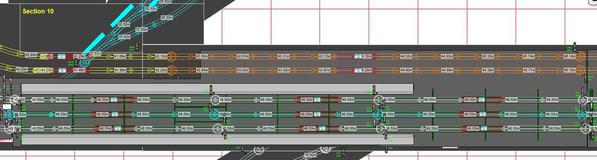

Here is the section shown as part of an RR-Track file for the entire project. The current detectors are shown as DA5-01 and DA5-02. The signals are also displayed. The layout will consist of two three track lines (A and B). The "A" designation is for Line A. The "5" designation is for Section 5. The signals shown in italics are repeating signals from other sections. Section 5 is a 2 track loop section off the main 3-track trunk line. This allowed me to build a simpler circuit and I was able to combine the accessory and controller circuits on a single board. Mind you some sections will have up to 13 current detectors and between 15 and 20 signals.

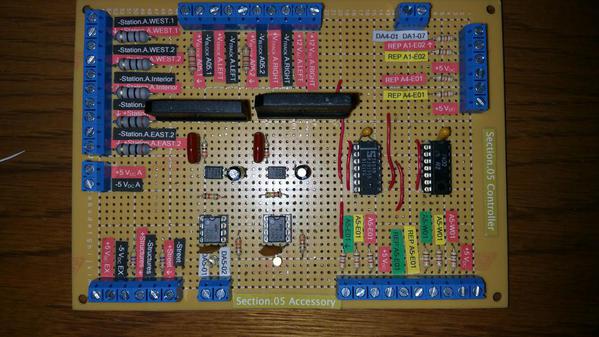

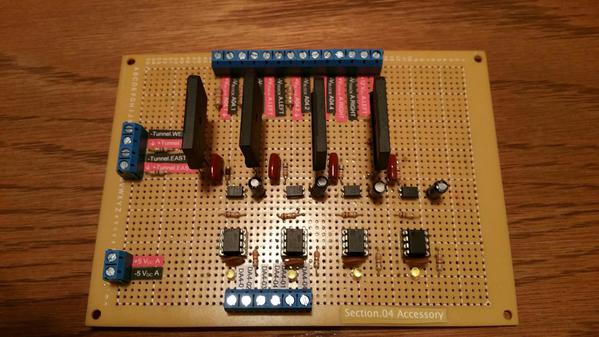

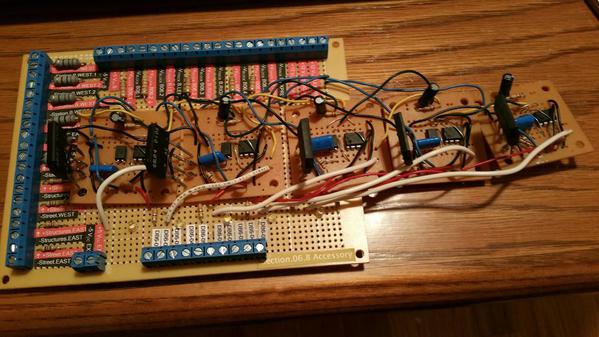

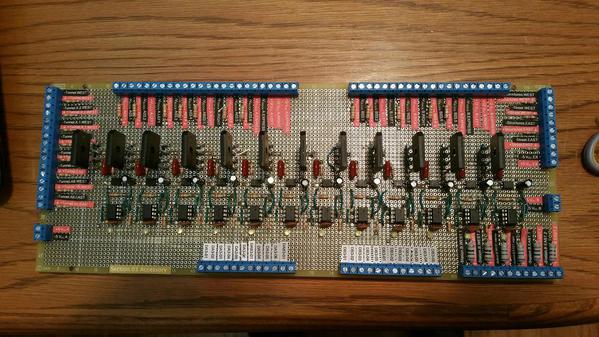

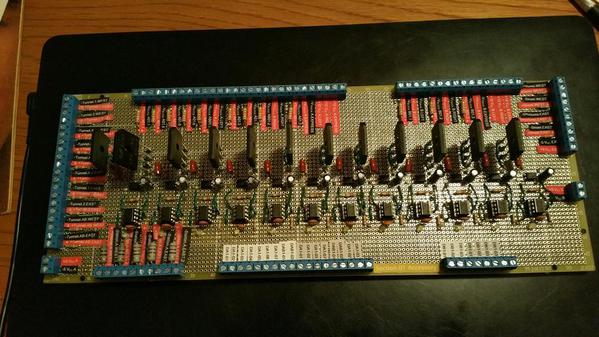

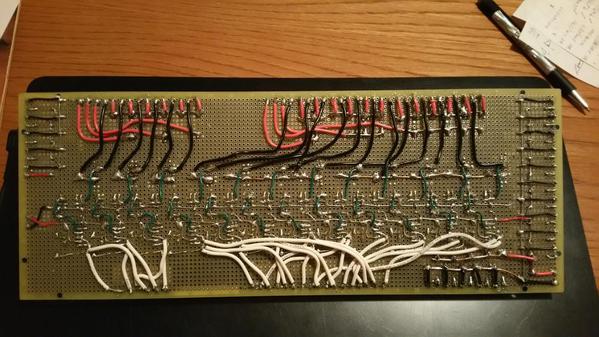

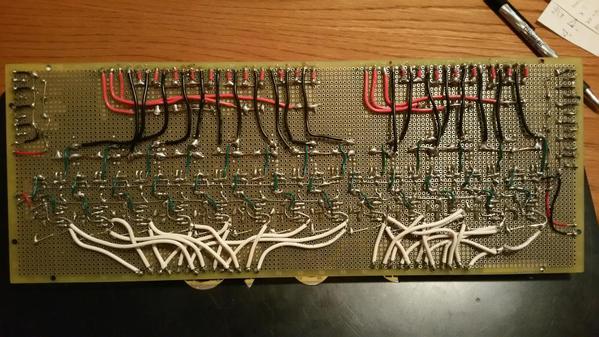

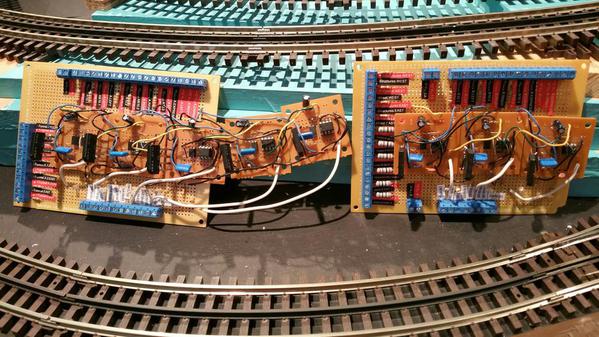

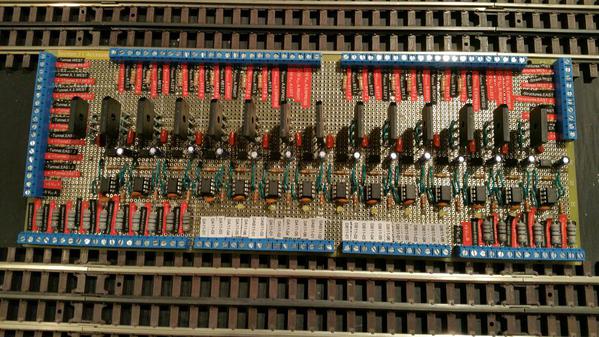

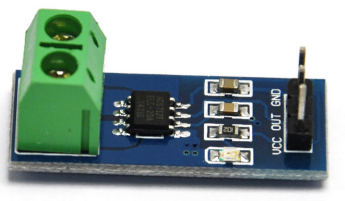

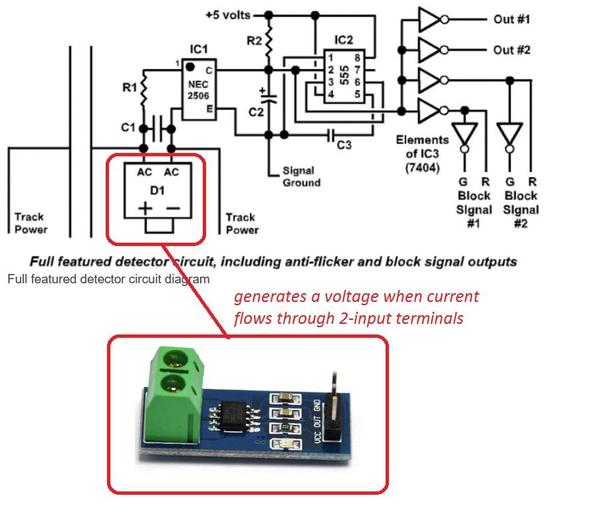

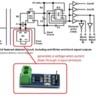

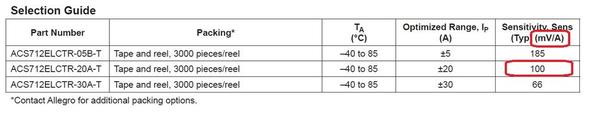

The circuit below was designed using a product called LochMaster. It is assembled on Radio Shack perfboard. To the left are the current limiting resistors to control the station lights. The are heavy duty (1 watt) as there are many LEDs to light for each section. The resistors at the bottom will control street lights and building lights. At the top are the inputs from the track and the two blocks that require current detection. There are inputs for trickle power that will allow for current detection should the main power be shut off. The current detectors are using the bridge rectifier/optoisolator/555 design. The downside here is the 1.4 volt drop to the train power. I supplied an LED for each detector as a troubleshooter in case of any failure. The detector outputs are fed into the signal controller circuit on the right. They also have outputs designated DA5-01 and DA5-02. These signals will be used by neighboring sections. Also note there are inputs DA4-01 and DA1-07 from neighboring sections. The outputs to the signal LEDS are shown. Each has a current limiting resistor and the design uses the common anode technique.

I considered using Arduino as this would eliminate the controller circuitry, but decided against it since it would be easy to short pins and damage the board. PCB would be nice, but it is very expensive. For heavier duty inputs 18 AWG wire is used instead of the 22 AWG. This is shown here. All bus wire between sections is 12 AWG.