thanks, guys.

appreciate the comments.

I have to agree with ya': Scott did a great job on this baby.

Yes, it's TMCC.

Hot water: funny you should mention a Z-8: picking a Z-8 and A-4 (grey boiler) up on Saturday

=======

NP Z-5 (cont)

I actually read the manual and it said to run her dry in the conv. Put her on the track and turned up the juice: lights came on but she just sat there.

MMMM: Old battery, replace that and see what happens.... same thing!!

Well, let's try uploading her to TMCC and voila, all works. Not sure why the conv didn't work, BUT, better working TMCC versus no conv. Probably something I screwed up: check it later.

======

Well, after the short dry run to make sure no binding, I picked her up for oiling and a few parts fell off. Getting move all the way from Korea, and then to the original owner and then to me: those boxes aren't always handled with the best of care by the movers. There's also a lot of mass in this engine so it's going to move some in that box.

Thinking about it, the sender used masking tape instead of the original box tape. Masking tape can stretch whereas box tape is like iron.

No big deal, all the parts were an easy fix.

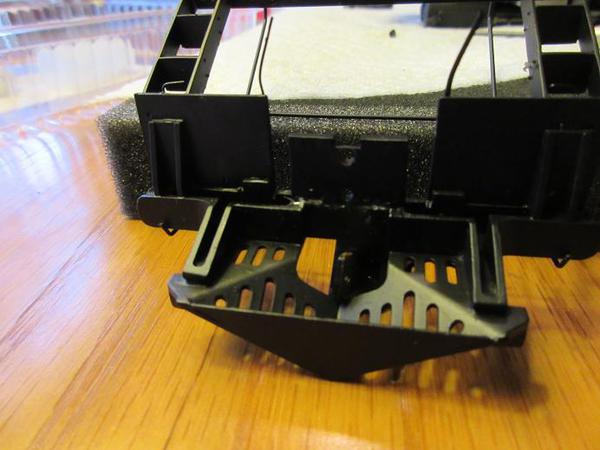

Initially, the pilot was loose. Sticking way out front, I can see that part being vulnerable (those shipping guys just throw those boxes around). The solder joint from the pilot to a plate that screws to the front engine was broken. I didn't want to resister solder as everything is painted so I used thin CA: not sure if this will hold up in the long run with such a small surface area to glue.

I removed the front engine from the boiler. Swivel screw at the back, plus two screws holding the swivel steam pipes going to the front steam chests. The return steam pipe (center of front engine) was broken. The solder joint holding the two pieces of return steam pipe broke. I used JB quik weld on these two parts. Plenty of surface area as one piece of the pipe is solid and the other hollow so slopped the jb weld on both parts and let them dry.

NOTE: I had to do more PM on the front engine and the return steam pipe broke on me. So to fix it right, I drilled a hole in the end of the front solid brass piece, used JB weld again, only put a piece of piano wire in the hole between the two pieces to give it a lot more strength than just the original surface area strength.

Lifting up the engine, that front set of drivers hanging there can put a lot of stress on this part.

While taking the front engine off, it looks like I broke a wire. It's from the boiler and it seemed to be the ground wire for lights so I soldered the wire on to the ground tab. (must of been right as all worked! )

![]()