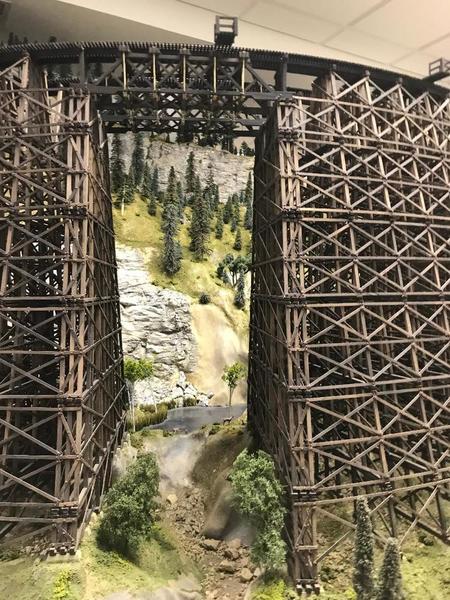

There are no speed restrictions. I've run trains at 60 smph over it. It is an 8' two track semicircle 3' high at it's tallest point. There are 23,000 nbw castings attached to it. The brass rods on the bridges are actually threaded with 00-90 treads w/ matching nuts. The bents are made in 6" tall sections, stacked and glued. I made jigs for each section, then jigs to stack the completed sections. It was built upside down and took 4 people 5-1/2 hours to flip it and put it in place. There are 1,100 trestle ties with 6,600 spikes. It took 3 years to finish. I had a friend who was helping me design the layout because it was the first I've ever done. I told him I wanted a trestle and asked him how big I should make it. He said make as big as possible so I did. He had a cad drawing of a bent that he blew up to actual size and I used that as the guide. Where I worked I had access to a Bridgeport mill and I used that to mill out pieces of acrylic for the jigs to make sure the jigs were perfectly parallel top to bottom. If I had known what I was getting into I would have made it a lot smaller. lol. It is very sturdy. Every upright post has a screw on top and bottom. I never actually counted them but it was between 3 and 4 thousand.

There are no speed restrictions. I've run trains at 60 smph over it. It is an 8' two track semicircle 3' high at it's tallest point. There are 23,000 nbw castings attached to it. The brass rods on the bridges are actually threaded with 00-90 treads w/ matching nuts. The bents are made in 6" tall sections, stacked and glued. I made jigs for each section, then jigs to stack the completed sections. It was built upside down and took 4 people 5-1/2 hours to flip it and put it in place. There are 1,100 trestle ties with 6,600 spikes. It took 3 years to finish. I had a friend who was helping me design the layout because it was the first I've ever done. I told him I wanted a trestle and asked him how big I should make it. He said make as big as possible so I did. He had a cad drawing of a bent that he blew up to actual size and I used that as the guide. Where I worked I had access to a Bridgeport mill and I used that to mill out pieces of acrylic for the jigs to make sure the jigs were perfectly parallel top to bottom. If I had known what I was getting into I would have made it a lot smaller. lol. It is very sturdy. Every upright post has a screw on top and bottom. I never actually counted them but it was between 3 and 4 thousand.

Replies sorted oldest to newest

Simply beautiful. I’m sure many many hours invested on it.

Great job, to say the least.

Username checks out.

Wow, that's some pile of sticks!! ![]()

Amazing work!

Love it. Something to be really proud of.

WOW !

The bar continues to rise...

The mind boggles! ![]() I can say with certainty that I'll never have anything like that on my layout, I probably won't live long enough to get it built!

I can say with certainty that I'll never have anything like that on my layout, I probably won't live long enough to get it built! ![]()

Wowzers. That's amazing!

Great work.

That is totally awesome. WOW looks really good. ![]()

That's one of the sexiest things I've ever seen in my life.

Wow. Just wow. That's amazing!

Well, this closes the debate for Best Trestle of all time award.

Retire that trophy. ![]()

Labor of love.

Best I ever seen!!!!!!!

Threading the rods must of been a chore. Was it all hand done with a 00-90 die and die handle or did you use a lathe with a 00-90 die at the end (slow speed with reverse or hand turned).

Wow! This built by one person and to think I have trouble putting a piece of Ikea furniture together. LOL!! Great Work!

jhz563 posted:Username checks out.

Haha! Made me laugh out loud.

Trestleman1 posted:There are no speed restrictions. I've run trains at 60 smph over it.

I would love to see a video of that!!

It was built upside down and took 4 people 5-1/2 hours to flip it and put it in place.

I've never built anything like this, so I'm curious as to why it was built upside down first?

Amazing and beautiful work! Any other tips to share that you learned along the way?

Very, very fine work!

And you are braver than I would be, to run trains at 60 smph over the bridge. Keep on keeping on!

Ron, 80 rods both ends done by hand for the 2 bridges. I used an expandable die. I had to expand it as far as it would go, then run a light thread, tighten up the die, repeat this step until I could get a nut on it. There is no way I would have tried this on the big lathes that were available to me. I don't think the 3 jaw chucks we had would go down that tight. lol.

Conrail, The friend who gave me the cad drawing that started this whole project helped me lay out the semicircular stringers to mount the ties to and gave me a little help when I started mounting the bents to the stringers. He was also one of the four folks who helped me flip it into position.

Don

Trestleman1 posted:Ron, 80 rods both ends done by hand for the 2 bridges. I used an expandable die. I had to expand it as far as it would go, then run a light thread, tighten up the die, repeat this step until I could get a nut on it. There is no way I would have tried this on the big lathes that were available to me. I don't think the 3 jaw chucks we had would go down that tight. lol.

Conrail, The friend who gave me the cad drawing that started this whole project helped me lay out the semicircular stringers to mount the ties to and gave me a little help when I started mounting the bents to the stringers. He was also one of the four folks who helped me flip it into position.

Don

Understand as I did a lot of work on my steamboat launch model with 00-80 & 1-72 screws for boiler assembly. A collet lathe would work but it was best on what you did to narrow the end to get the screw on and threading started. For me treading by hands is the best as you have more control. Great Job!

JD2035RR, You build it upside down to make sure the top is level. If you tried to start at the bottom with 45 bents there's no way you could keep them all level all the way to the top. I flipped the trestle and suspended it from the floor joists at the exact height I wanted it. I had 432 concrete pilings I had cast using epoxy resin. I then installed just the pilings on pieces of wood. Then I raised the trestle back up 2 feet and filled in the scenery around the pilings. Then lowered the trestle back onto the pilings.

I'm in the process of rewiring my layout but I should able to run trains by Monday. If I can figure out how to post a video I'll try then.

Don

Answers a question I had and makes perfect sense! I also wondered about building it upside down, and that's an excellent reason! ![]()

As I stated on the other thread could be a Wonder of the World in O gauage!!!! Keep up the good work TRESSLEMAN!!!!!![]()

You're sick like Elliot ![]()

![]()

![]()

![]()

Adriatic- What are you talking about?

That is a work of art.

Who is Elliot?

that is a great job

I don't even know how to compliment that it is so awesome.

Ed

BTW - Thanks a lot, I will be taking down my totally inferior pitiful, lame trestle bridge tomorrow ![]()

All I can add to all of the compliments above is - that is truly museum quality. Beautiful work.

Ed, any trestle is a good trestle in my book.

Don

Trestleman1 posted:Adriatic- What are you talking about?

It's obviously a huge undertaking; more than the average personality would knowingly, yet still happily set out to accomplish in such an intricate fashion. It is somewhat on par with Elliot's "Dream/nightmare layout" imo; astonishing in the amount of effort put forth. I bet a new car doesn't even have 3000 nuts and bolts. ![]()

The two parallel tracks on the surface seem to be too close together, maybe by 1/8". Had you noticed that before you started?

JUST KIDDING. I figured somebody had to act like a dour rivet-counter...

In all seriousness, that is one of the finest pieces of modeling I've ever seen. Fantastic. If visitors come to your house and don't say too much, forgive them, because they're clearly dumbstruck. I know I would be.

Wow. Big, big wow.

Steven J. Serenska

Stunning! Fabulous modeling! Congratulations.

Don Merz

Sean,

Love the pic of the Kinsol trestle. Do you have any other pic's of it?

Elliot is also known as "Bigboy" Trestleman. Here is a link to his little project ![]()