so this puts me back to the set screw on top thinking as if it's too tight it wouldn't let it turn also.

I think that you need to set it up on a block and run jumpers from the track to power it.

Have you looked at the trucks to see if a traction tire is binding on the side plates? A piece of packing foam or something?

The motors are trying to run. Something like old grease or a traction tire or something seems to be binding them.

I don't see any reason to adjust anything on brand new motors that are trying to run.

I agree with Chuck but... Are both motors facing the same direction? I f not one has to run in the opposite direction .

I would disconnect one motor for starters and see if the other one will rev up.

You should be able to turn the motor armatures with your fingers to verify which way they need to turn to move the wheels in the sme direction. With the shell off and the engine on its side, simply move the armature and observe which way the the wheels are turning. I would be surprised if an engine that had never been run would be wired wrong.

Pete

That's the problem, the engine was never run (at the factory level.)

rtraincollector posted:I just proved myself wrong they do need to be going in opposite directions. i see my mistake now. After rereading

Glad you tried it RT, ![]() See what I was trying to say?

See what I was trying to say?

I WOULD NOT start pulling wires off of anything. Even if it is wired wrong and I would bet it is not. Just hook it up to power off the track and the motors will run if pulling against each other is the problem and you will be able to see if they are running in the wrong direction.

Sound like it is new but 9 years old, so it may just need to be lubed and run in some. It also sounds like the seller is willing to help out.

You have options.

Okay so. Push the armatures to see which way the whells are turning. Then if turning in the same direction apply lube lossen the set screw 1/4 of a turn. But under no circumstances pull wires all gun ho.

It's not wired wrong. Don't change anything with the brushes. With the FM(or any, for that matter) motor trucks facing in opposite directions, one armature must turn CW & the other CCW.

I removed my previous post as I checked and had wrong information. The armatures should spin opposite as many have stated.

Does the reverse unit get really hot? That would be my next check.

In my opinion and from the looks of the video , something is binding.

Alex

One small drop of oil on the armature pin is going to fix this engine... ??? maybe.

Bill: Where do you live in Florida? I'm near Jacksonville; if you're near, I can help you if needed.

Larry

I live in defuniak springs.

D&H 65 posted:Bill: Where do you live in Florida? I'm near Jacksonville; if you're near, I can help you if needed.

Larry

I think you mean southern railfan, I'm in S.C. but you would be the closest and if you two could get together that would be awesome. I was offering as didn't see anybody closer than me until you stepped in ![]() .

.

That's too bad.... If you really get stuck, mail or FedEx it to me and I'll look at it for you; there can't be too much wrong with it. I notice you have a CW-80 i the background; is this your sole power supply? A two motor Pullmor engine will likely need more power for satisfactory operation. If you have larger transformer, try that at least and see if operation is improved.

Should you want to send it to me, let me know and I'll give you an address.

Wow hes almost to AL out on the panhandle.

Thanks. If there is Any rewiring to do I will let you know.

It lives!

Gregg posted:Maybe lift one end of the engine OFF the track and check out the direction of the wheels. Isn't there an adjusting screw on top of the motor that puts tension on the armature ? I probably would loosen it off a bit and slowly tighten it again.

Can someone take a picture of where the so called "adjusting screw" is located on a Pullmore motor? I have l looked for one but can't find where it is located.

Thanks

Bob D

Sure. But the locomotive is working now it runs fine but if you want a picture i will get you one.

Southern Railfan.... What did you do ?

I borrowed a old postwar transformer and tried it and it worked previously I was using a Lionel cw-40 to power my layout. I am going to get a new transformer do think the cw-180 will work any suggestions?

Here it is running.

Attachments

southern Railfan posted:I borrowed a old postwar transformer and tried it and it worked previously I was using a Lionel cw-40 to power my layout. I am going to get a new transformer do think the cw-180 will work any suggestions?

Do you mean CW-80. It probably would work but I personally would go with something a bit more. A lot probably will suggest a MTH 4000 I would say get a post war R,RW,LW,KW etc. Even a ZW but you will also need to get fast acting breakers/fuses to protect your engine's electronics. Even with CW-80 you need that.

southern Railfan posted:Here it is running.

![]() Did I see a KW? I still have mine from 1950 something. Nothing else though just the KW.

Did I see a KW? I still have mine from 1950 something. Nothing else though just the KW.

rtraincollector posted:southern Railfan posted:I borrowed a old postwar transformer and tried it and it worked previously I was using a Lionel cw-40 to power my layout. I am going to get a new transformer do think the cw-180 will work any suggestions?

Do you mean CW-80. It probably would work but I personally would go with something a bit more. A lot probably will suggest a MTH 4000 I would say get a post war R,RW,LW,KW etc. Even a ZW but you will also need to get fast acting breakers/fuses to protect your engine's electronics. Even with CW-80 you need that.

The PowerMax Plus(CW-40) is definitely not enough for this engine, the CW-80 would be almost tapped out with this, the GW-180 would be more than enough.

Gregg posted:southern Railfan posted:Here it is running.

Did I see a KW? I still have mine from 1950 something. Nothing else though just the KW.

The borrowed KW is obviously fine too, but it lacks a bell button.

I probably going to get a GW-180 I like the look and It's easy for guests to use I also like the being able to hook up an accessory

The engine has a horn and bell it only activates the horn not the bell.

Correct but wire it in reverse and it will operate only the bell ![]()

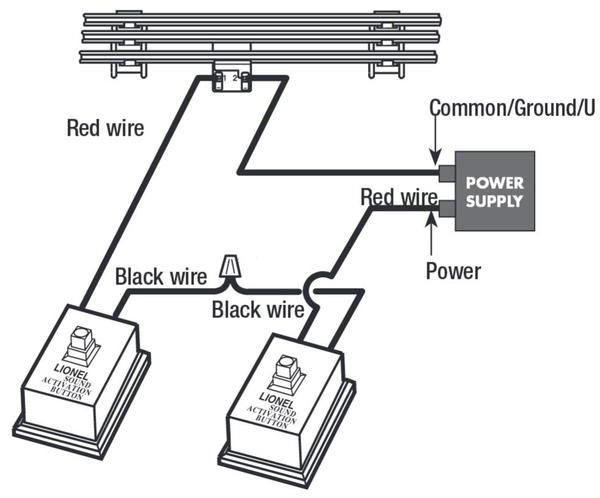

you can buy or make a whistle and bell controller that goes between the transformer and the track in wiring

Really, how do make one?

I'm sure GunrunnerJohn and few others could tell you as thats beyond my electronics knowledge

southern Railfan posted:I borrowed a old postwar transformer and tried it and it worked previously I was using a Lionel cw-40 to power my layout. I am going to get a new transformer do think the cw-180 will work any suggestions?

As soon as you stated CW-40, I knew that was the problem (seriously, I did.) I have a PW trainmaster that I went through, cleaned out the old lube, cleaned the ball bearing races, etc. I tried to run mine with a CW-80 and it couldn't do it. The green light on the transformer started to blink which I assumed was an overload. I hooked a PW ZW and off it went. I was really impressed with how smooth it ran. I never gave Trainmasters much thought until after that.

Steve

southern Railfan posted:Here it is running.

The engine has a noticeable wobble when it's running. Does it have traction tires or magnatraction?

Steve

Its magnatraction equipped.

Southern Railfan,

Glad you got it running without tearing it apart. I would still suggest you do or get a full lube job on it as old as it is. even though it is new. I thought you had a CW-80 and like Rob said a CW-40 had no chance. They are only good for small can motors. Maybe you could use it for accessory lighting.

The GW-180 will have no problems.

Enjoy!

What whistle control would work?

The No.66 whistle controller

or

The 167 whistle controller

I can't find a good deal on a GW-180 I will probably buy one at my local train show this year.

southern Railfan posted:What whistle control would work?

The No.66 whistle controller

or

The 167 whistle controller...

The Lionel 5906 is probably the simplest way to add bell function.

Or, if you are using a Type Z/V etc., w/o any whistle or bell control, you use two:

southern Railfan posted:I can't find a good deal on a GW-180 I will probably buy one at my local train show this year.