This year I settled in as a retirement newbie and so far I'm really enjoying myself. Here's how I spent this year's summer, besides all the other chores. Some may laugh, some may cry, some may curse, some may cheer, but I hope all will find something here to enjoy for a bit. I plan to build this once and not to have to do this again. ![]() Who hasn't said that? The more eyes on a project the more likely mistakes and gotcha's will be avoided so input is always appreciated. One can only hope.

Who hasn't said that? The more eyes on a project the more likely mistakes and gotcha's will be avoided so input is always appreciated. One can only hope.

Why Turkey Hollow? I have some interesting neighbors who throw some wild parties. These guys are much more interesting that I am. And our house sits down from the road quite a bit. No turkeys were harmed or killed during railroad construction to date.

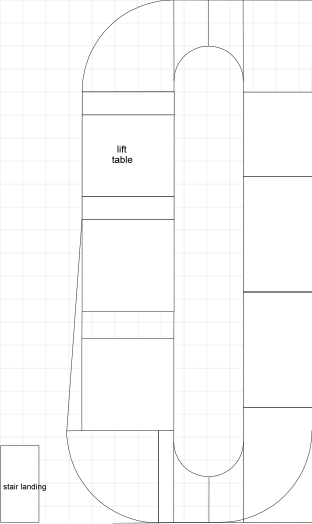

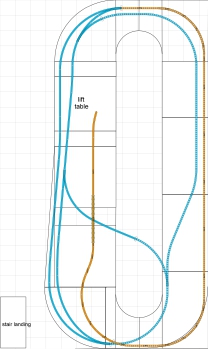

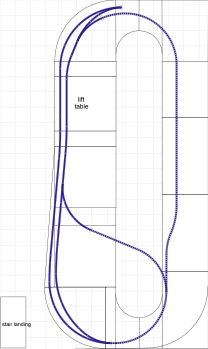

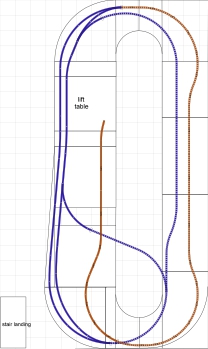

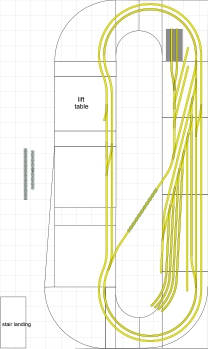

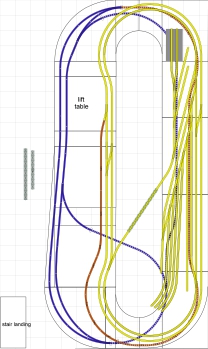

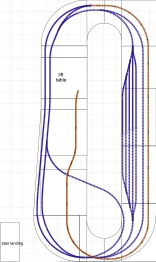

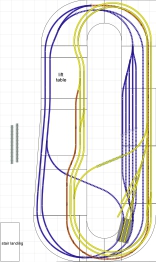

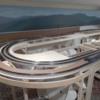

The layout for Turkey Hollow Railroad has been limited to approximately 22 x 10 feet of my finished basement and is bounded on the bottom (east) and right (north) by the interior framed walls. The left and top, south and west, sides are open walkways. These requirements and the desire for a wide center aisle have pretty much set the bench design for the first level.

The southside is made of 48" wide sections. With the exception of my lift table which has a 66 1/2" length, and one small filler, the sections are also 48" in length. The curve in the lower right corner is the anticipated curve of the backdrop to be installed. There will be some access behind the backdrop.

How good, or bad, is a design using software (anyRail in my case)? I believe like most things software, the results are as good as the effort put in. Spoiler alert! I've already built the top and left sides. When I cut the pieces for the filler between the to 48 x48 tables it was with 1/2" of the plan. It is tedious and a little painful to do freehand drawing with these software packages but it is possible to get good results. How well one can measure the room also has a great deal to do with how good of a model you can build in software.

I chose to build with furniture grade plywood, specifically arctic birch plywood, pocket screw joinery. This is the multi-layer, metric plywood you may see mentioned often. This choice was made based on price and uniformity of the material. I don't like paying $8+ for a curvy, wavy, stick of wood. My local supplier keeps a decent stock but the price has jumped over the last year, 69.95. I rip a sheet down into 3 1/2" wide strips, 16 per sheet. A 1 x 3 1/2 x 60 for less than $4.50 each. I takes 5 sticks to build a 48 x 48 table using 16" centers.

There are two, 48" radius curves at the ends of the southside, and there are two, 36" radius curves at the end of the middle walkway. My local supplier carries Whacky Wood (goes by several names, it's bendable plywood) for $38 for a 4 x 8 column which I ripped into 4" x 96" strips. This stuff is only 5/16" thick so I chose to use three strips for each curve so they would be at least 3/4" thick.

Once I cut the two sides and braces at 16" centers I laid out an approximate 48" arch on some scrap plywood and built a form. The whacky wood bends uniformly and helps this process along. If your cuts are true this will work well.

Here are three strips, formed and cut to length, ready for gluing up.

Glued and back into the clamps.

It just so happened that the location for the lift table was very close to the high point of the floor so I carefully set that table first, being triply sure to measure the distance from the long wall on the opposite side.

Once I build this benchwork, lay track, and wire things up I will reach the extent of my knowledge and experience with model railroading. That will begin a much slower, and hopefully relaxing, pace. I decided I will add a backdrop in hopes it will give me some inspiration for scenery. The bench work stopped and I popped open the ceiling tiles to locate the studs and added a valance to hang a 36" backdrop. The valance is right about 86" high and it is working out that my second layout level will be around 50" so it will be close to a good height. I used some 1/4" tempered hardboard I had in the scrap bin for the valance. It is 4" wide and I plan to hang the backdrop from it using double sided carpet tape.

At this point I built the 36" inner curve section and a 36" x 48" table to complete the west end. Once everything was squared and leveled up the 36 x 48 table was secured to the wall studs with #10, 3" deck screws.

This week I finished the main structure of the southside, where I'll pause until the backdrop gets installed. It may be a few weeks until I order one.

The legs are laminated 1 x 7/8 wide strips of two, 18mm (3/4") and one, 12mm (1/2") plywood. 48mm is approximately 7/8". I capped off the ends to help protect the plywood layers and give threaded inserts a good surface to seat on. Most all legs are set back 4 1/2" from the edge.

The plan was to have 39" height, I cut the legs 38 3/8" long and with the 5/8 for the leveler it should have worked out. What I didn't account for was the need for a jam nut (~1/2") and the addition of the 3" diameter plywood "hockey pucks" advised by Tom Tee that add about 5/8" to the height. In the end the lowest point is 40" off the floor. Not to design but I won't lose sleep over it. And those round plywood pucks with some plastic carpet pad on the bottom really made leveling possible on the carpet, even with no pad under.

That is where I stopped last evening. I'll be finishing up some odds and ends for a little while. I'd like to get on past this structural phase and begin the next steps in building the railroad parts, which is really where I need the most input. I have something of a track plan started, and some scenic ideas that I will share when they seem a little more evolved.

You may have noticed all the extra junk laying around that I have to keep moving out of the way. I've at least moved the heaviest stuff onto furniture dollies. ![]()

Thanks for playing!