Team,

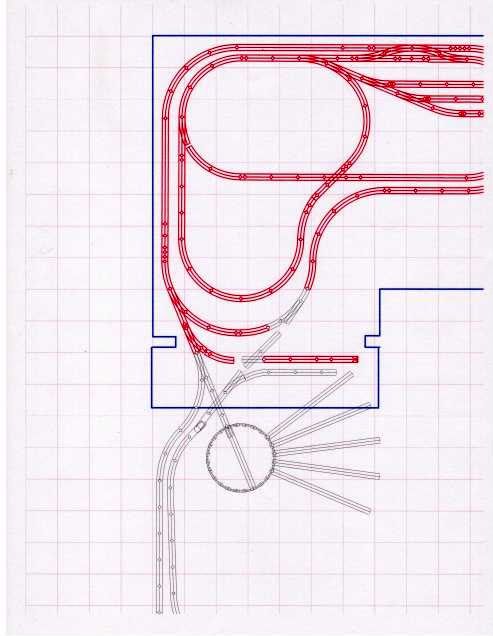

I am about to purchase and install my first turntable so I am trying to plan with options. Sorry but I have some very basic questions that I am hoping more experienced modelers can give me some direction on the overall plan and what the scene needs to look like

1. From the table pit, what is the average / prototypical length of the visible tracks to the front doors of a round house or Diesel Shed. I have heard anywhere from 8 to 10 inches is best.

2. What is the average depth of the Roundhouse or Diesel shed. I am looking at Korber as they provide a scale. Is that the best - scale I should use for planning purposes?

3. Did railroads with roundhouses typically have a set or tracks that went around the back of the Roundhouse? I have seen a wide variety of pictures on the Internet but not sure if the RR's did that. Historians - please help.

Thanks in advance.

Kevin

Parts/panels windows take some time to get right. Older 304 Korber model parts were poor, from the box, and required a lot of adjustment work. The color pictured, is a dye, install as part of the casting, the second Korber 304, that I did, was painted with Rust-oleum ruddy brown primer for the brick color.

Parts/panels windows take some time to get right. Older 304 Korber model parts were poor, from the box, and required a lot of adjustment work. The color pictured, is a dye, install as part of the casting, the second Korber 304, that I did, was painted with Rust-oleum ruddy brown primer for the brick color.