With the glue dry I painted the cork this morning. Got to run some errands today but I hope to get the track down later today. Some pics.........Paul

if you would like. I can snap a pic of how it is laid out under the buildings

That would be GREAT!! Thank you.

The last few days, I've quietly been working on the last complicated bit of track. I've been chopping 072 switches to create an 8 track ladder with 4" spacing for the A yard.

To do this, I remove all of the "excess" rail and ties on the straight leg of each switch. On the frog end I cut all the way back to where the guard rail starts, and throw away the nub next to the frog. On the point end, I remove everything up to the points, but leave the bit of curved stock rail to fill in to the next frog. It's kind of like a puzzle.

Back at the computer, I created one of the most interesting spreadsheets to date - a punch list. Across the top, I divided the layout up into logical sections, then listed all the different projects down the side. I filled in the body with percentages to indicate the level of completion. I was able to fill in most of the table from memory, but there was still a bunch of running back and forth to verify current conditions.

This is Joe. See Joe wire. Wire Joe wire!

As I was sitting there helping Joe, I turned and looked back down the aisle, and this is what I saw. Before Joe on the left, after Joe on the right.

I filled in that section of the punch list with 100%. ![]()

Attachments

Elliot - We have chopped Atlas switches like that to achieve track spacing. It works great, but we then had trouble with many of our engines not being able to run through them without stalling. So, we had to power route the switches. Installing additional pickup rollers would help too, but not as easy as it sounds.

Looking great!

Art

AMAZING !!!!!!!!!!!!!!!!!!!

I've said it before and I'll say it again---- WOW !!!!!!!!!!!!!!!

I would NOT even have a clue as to where to start, cutting 072 switches apart in order to make what YOU want them to be !!

Elliot-- Where did you learn all this! You should sign up with the NMRA as a Technical Support guru or such !! Maybe even their President Emeritus !! (grin)

My wife Suzie wants to know just how BIG your basement space really is !! It appears to be long and narrow !! Maybe I forgot, BUT, is their a physical connection between your different levels ?? And those darn light bulbs-- I just can't get over the amount of HEAT in that layout space !!

By the way, who the heck needs YORK ???

Go to Elliot's house instead !! Put some tables in your front and back yards for vendors. Everyone else goes downstairs. Have LUNCH catered !! OGR and NMRA folks can run Clinics and slideshows !! Have plenty of coffee and juice on-hand !!

Bottled water too.

Charge a modest fee for admission, to cover Lunch and whatever.

I, am downright serious folks. Elliot needs to consider this and share his masterpiece with the overall railfan /hobbyist fraternity !

Take care and continue your superior expertise !!

Cheers.

Ken Shattock

Federal Way, WA. (KRK)

Art, I remember you telling me about this, and I have kept it in mind since then. My problem is that these will be manual switches, so contacts are going to be very tricky. In the case of the A yard, I may try to modify the rollers on a few engines to cope with the problem.

Ken, tell her the the space is 38'x42' with an extra piece in one corner for a total of 1900 sq ft. The reason it always looks long and narrow in the photos is that the layout consists of 3 peninsulas of staggered lengths in the long dimension. Now that the backdrops are up, you can't see across the width anymore.

There is no real heat from those light bulbs, they're LED's. Less than 20 amps to light the whole room.

Where did I learn all this? Well I use to hand lay track back in my younger days in both HO and 2 rail O. So to do these chops, is actually fairly easy by comparison. Then there were a bunch of clubs along the way, as well as the whole enterTRAINment experience.

It is funny that you mention the NMRA, I have been a member for 40 years. I recently volunteered to be the layout tour coordinator for the local division. Part of the plan is to get the layout "discovered" by the locals.

Over the last couple years, I've had the pleasure of a few visits from forum members. The invitation is always open. If you are coming to the Twin Cities, drop me an email to set up a time.![]()

Playing catch up on the posts. A lot of great work being done. Elliot's modifying the 072 turnouts with how he did it was great. His work and solutions has been a great inspiration on my planning. I just wish I had his space to work with.

As for me, Kadee conversions continue but now at a point that I need to start doing engines and Waycars. I had to repair a brand new engine MTH GN GP30, Two issues and drawing a huge amount of Amps to run and engine was not receiving the watch dog signal and would take off like a jack rabbit with no control in conventional mode. Fixes were simpler. Removed the shell and discovered the wires leading from the trucks had were to tight and had pulled loose at the connectors at the board, Tach reader was rubbing against the fly wheel and the wires had com lose at the connector on the board. Another thing to note, was whoever also at the factory who connected the zip ties was so tight the that the connectors were pulled almost sideways bending some of the pins and wire had been pulled loose. All easy fix straightened the pins pushed the wire ends back into the connectors, increased the gap on the tach reader and rezip tied the wire leaving plenty of play. I also discovered when I pulled the motors from the trucks that they were bone dry!!!. Put it back on the track and was finally able to load it into DCS and conventional control was also restored. I still had a huge amp draw with the smoke unit on. On a wim and after calling G, I swaped out smoke units and amp draw was back to normal. On closer examination I discovered that the motor was all but sized and the heater element its self may of had a short because it had that burnt wiring smell.. So much for QAQC at the factory. The next was simple I swapped out shell from the dummy unit with the shell and pilots from my other GN(BSB scheme) GP30.

The lemon that now runs like a champ.

Dummy now a power unit

The powered unit now is a dummy.

Attachments

The last few days, I've quietly been working on the last complicated bit of track.

...

As I was sitting there helping Joe, I turned and looked back down the aisle, and this is what I saw. ..

Quite a view, Elliot, which made me try to imagine something. You see, when I landscape a layout, inch-by-square-inch, I use these tools:

tweezers, of varying lengths; eye dropper; dentist's pick; chopstix; scissors; small paintbrushes; long-handled teaspoon.

I cannot even imagine how much time it will take you to landscape that huge layout. Being a master-planner, you have likely given that aspect of your creative adventure a lot of thought. Would you care to share how you see that aspect of your layout progressing, sir?

FrankM.

Attachments

Frank, I've always loved the meticulous nature of your work and your attention to detail. Truly spectacular!

My layout is quite different in its focus. There will be scenery, but it is incidental to the trains themselves. There will be very few 3 dimensional structures because most of the layout is railroad property. Because the area I'm modelling exists in the real world, I can actually take pictures of what exists. It is primarily an urban landscape with commercial buildings lining the tracks. Probably very few people or vehicles will be used, I just didn't leave room for those things (on purpose).

The primary scenic element, after the trains themselves, is ballast. There will be some greenery, just not that much. The entire upper deck is just one long string of yards, six of them, back to back to back... with double track mains running through.

Today I got most of the track laid down going to the station. On the siding on the back side of the station I added an uncoupling track. Now as I am finishing off the other two sidings I am thinking of maybe adding an uncoupling track to those also. If I decide to do that I'll have to see if one of the local hobby shops may have some in stock. Two of the pics show sidings where I would p[lace the uncouplers. The back siding the uncoupler is by the small freight shed. By adding uncouplers to all the tracks I would then have the option of using all the tracks at one point for unloading and loading cars................Paul

Attachments

I finally got this transfer caboose into the paint shop. It sits atop a Centerline Products track cleaner.

Attachments

Good Morning, Everybody. Been hard to find time to work on the new layout lately !

However, I ran the controller wires to all the 022/072 switches from central control.

But haven't hooked them up as yet. Some switches will have 153 block signals tied to the screw terminals for indicators.

OGR Forum member "Stewart Montei" has offered to assist with a track plan design for my proposed 2nd Level. Thank you, Stewart!

I just finished the construction of my new Accessory Control Panel. See attached Photo # 1. There are fourteen DPST toggle switches--- Four SPDT push-button switches---

and Three DIALCO panel lights: Green, Red and Yellow...

The toggle switches will initially be used to provide on/off power to the Sawmill;

the Greyhound Bus Depot, the Diner... Also power to Display Track 1 (three ATSF 70-foot passenger cars); Display Track 2 (four ATSF 60-foot passenger cars); Display Track 3 (four additional ATSF 60-foot passenger cars); Display Track 4 (Millenium Business Car); Display Track 5 (CSX SD-70ACe and Reading F-M Trainmaster units);

Display Track 6 (SP Cab Forward 4-8-8-2 # 4294) ...

The power to the passenger display tracks will provide lighting in the cars. The power to Display Tracks 5 and 6 will activate power units to sit there and idle (and act impressive looking) ... (Grin!)

On the new Accessory Control Panel, the four pushbuttons will be "Presets" ...

Momentarily depressing any one of the four pushbuttons will activate banks of relays for automatic routing of trains or trolleys without having to manually line up switches.

(My version of GRS "NX" nomenclature) ...

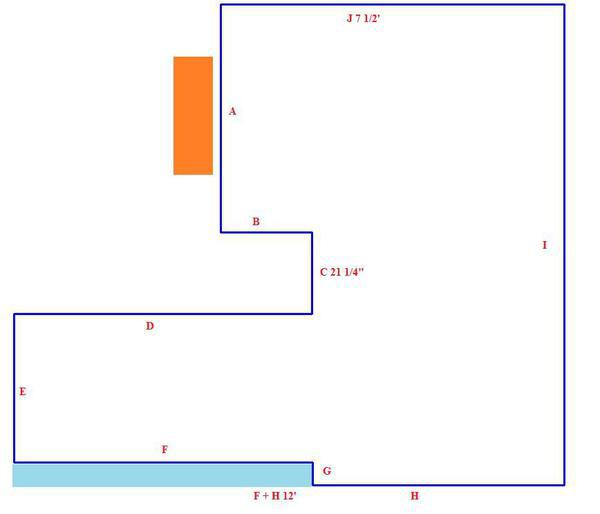

Photo 2. Total space available for Level 1 on new layout !

Photo 3. Rough track plan currently established on Level 1. Nothing fancy--just something for an old guy like me to play with !!

Stay tuned ! More to come !!

KRK

Cool, but photos not showing

Last night I worked on an incomplete Marx 999 motor and pony trucks assy, that came in, that was missing its collector. I scrounged one off another motor, soldered it to its wire, and got it running. At first it would reverse but now it will not. Still fooling with it, as I want to build a critter around it. I need to build/kitbash a tender for the Lionel

loco I kitbashed into #60 for the GW. I am hoping to find a usable one to kitbash, rather that scratch up a styrene one. The original one that came with the Lionel loco

would have been a good base, but I have already kitbashed that one into a tender for

another loco...not exactly planning ahead!

Cool, but photos not showing

By chance are you using Firefox? I can't see them either, but I can see a bunch of others. Someone posted a topic in tech support about this problem earlier today.

Cool, but photos not showing

By chance are you using Firefox? I can't see them either, but I can see a bunch of others. Someone posted a topic in tech support about this problem earlier today.

IE with Chrome as a back up. nothing. Older post most of the Pics are showing.

Today not a lot of progress. I ran trains and while doing that I added a bit of ballast to the area I am working on. Under the bridge I had applied some plaster so I dabbed on some earth color. Got to get on the phone to locate some uncoupler tracks so I can finish off the station area. I did back some cars onto the siding behind where the station will be and I think the other two tracks will work as possible unloading sidings.......Paul

I masked around more track that I had already installed and then spray painted it with Rustoleum Camo Earth Brown.

I tried a thinner wire under my curves on the curved stone arch bridge in order to super elevate the curves. This up under the edge of the ties gives a little more than a 1/16 inch lift. I am looking for the minimum raise that will give the effect that I want. I have a switch quite close to where the outside track starts to curve so I have to be careful.

Art

Here we go again...

Good Morning, Everybody. Been hard to find time to work on the new layout lately !

However, I ran the controller wires to all the 022/072 switches from central control.

But haven't hooked them up as yet. Some switches will have 153 block signals tied to the screw terminals for indicators.

OGR Forum member "Stewart Montei" has offered to assist with a track plan design for my proposed 2nd Level. Thank you, Stewart!

I just finished the construction of my new Accessory Control Panel. See attached Photo # 1. There are fourteen DPST toggle switches--- Four SPDT push-button switches---

and Three DIALCO panel lights: Green, Red and Yellow...

The GREEN panel lamp will indicate when the ZW is actually putting out power... the RED panel lamp will indicate when the KW is actually putting out power... and the YELLOW panel lamp will indicate when the LW is actually putting out power !!

The toggle switches will initially be used to provide on/off power to the Sawmill;

the Greyhound Bus Depot, the Diner... Also power to Display Track 1 (three ATSF 70-foot passenger cars); Display Track 2 (four ATSF 60-foot passenger cars); Display Track 3 (four additional ATSF 60-foot passenger cars); Display Track 4 (Millenium Business Car); Display Track 5 (CSX SD-70ACe and Reading F-M Trainmaster units);

Display Track 6 (SP Cab Forward 4-8-8-2 # 4294) ...

The power to the passenger display tracks will provide lighting in the cars. The power to Display Tracks 5 and 6 will activate power units to sit there and idle (and act impressive looking) ... (Grin!)

On the new Accessory Control Panel, the four pushbuttons will be "Presets" ...

Momentarily depressing any one of the four pushbuttons will activate banks of relays for automatic routing of trains or trolleys without having to manually line up switches.

(My version of GRS "NX" nomenclature) ...

Photo 2. Total space available for Level 1 on new layout !

Photo 3. Rough track plan currently established on Level 1. Nothing fancy--just something for an old guy like me to play with !!

Stay tuned ! More to come !!

KRK

Attachments

Received a pair of MTH Premier heavyweight 6 wheel trucks today and replaced a broken truck on a PRR combine for my local 4 car passenger train pulled by an Atlantic. I do not use lights on my passenger cars and so I removed the roller and assembly. Easy install for the truck and ran the train.

Today I walked past it twice, Then I went outside and trimmed the schrubs for 3.5 hours. Came back inside, showered and drank a beer.

I may walk past it again later this evening.

Yesterday I had a visitor from Australia stop in to look at my trains. He is nine years old and is visiting his father who is working on a defense project in the area. His dad is working with one of my cousins on the project and he sent him over to look at the trains. His dad bought him a small N-Scale set while he was here, si I gave hime a bunch of KATO Track.

I built the Atlas single track Pratt truss bridge. I wasted an hour because of the instructions. First step is to remove the screws from the ends of the vertical truss' and save the screws to use later. Well when later came it was a confusion. The screws I removed were not to be removed. The screws to be removed were never there in the first place. They were hidden in a plastic envelope. All was not lost however because d![]() uring the hour it took to figure this out I was able to expand my vocabulary a good bit.

uring the hour it took to figure this out I was able to expand my vocabulary a good bit.

Some areas of the layout will be difficult to get to in the coming months and almost impossible to get to for the lights above areas that are starting to get finished. With that in mind replaced all the lights in the train room to LED's. Was able to go from 65w floods to 100w equivalent LED's and change lighting from soft white to daylight. It really makes a difference and shouldn't have to change them for 22 years.

I bought a used "real"camera for the manual functions today.

Time to see if I can still shoot with a "real" camera.(vs point & shoot)

Or if I ever could. I did my own developing and feel that it gave my quality a boost.

Digital doesn't have that option.

So blame todays forum photo loading issues on me.

That's my luck, buy a camera on a day its troublesome to use![]()

I got a little free time and finished painting 2 corners and one full wall run, now I'm waiting on it to fully dry so I can attach it to the shelf and that will have half the room done. Not a lot but some progress.

My locos from Serge arrived today!

This GM&O GP-20 is seen escorting some postwar tin varnish around the layout:

If anyone's interested in the shell and chassis, let me know; the running gear is slated to be transplanted into a New Haven EF-4 Rectifier. ![]()

The slightly battered Berkshire found its way into the shop for a bit of valve gear adjustment:

As can be seen, the cowcatcher simply isn't anymore:

However, I do have plenty of donors for repairs.

Here's a couple happy snaps of the Giraffe Express' new steam power actually pulling a gi-raffe car:

And, of course, the markings have been changed slightly.

Mitch

Attachments

This morning was spent going to two hobby shops and getting one uncoupling track. This afternoon I finished off the tracks to the station. Then I placed the station in place and everything came out good. I added some freight cars and two RDC"s to see how it will look. So far I am happy with the outcome. I may tweak the middle siding uncoupling track to allow two cars to sit there. Just not sure on the track in front of the station if I will add a uncoupling track there. On the track leading off the mainline I started to ballast and added a second coat of earth color. Pics...........Paul

Attachments

Picture of the mine so far, and some other things I've posted about here but had no camera. As you can see, I seldom finish something till I'm pretty sure it stays.

This camera doesn't have the manual focus. Only manual shuttering adjustments.

I read a review with a mistake ![]() . I haven't figured out the macro settings yet.

. I haven't figured out the macro settings yet.

yea... this ones done and the elevated launch pads beginnings.

Nothing glued. Needs 4 timbers, wood texturing & a few weak color washes. I still want a trestle to raise the track, non-roadbed track, and a turnout!

The rocks groups are embedded in glue. Dead layout recoveries. Lots of Greenery yet to be stuffed. And maybe some wetness???

I hear the old flagman helped make the bricks for that mine.

I didn't like the tunnel face for this side

There is a good chance I'll just board up "Mine Table #83a", or turn it into a doorway.

Fantasy road name for the mine is yet to be decided.

I want to remake the bracket on this one, or at lest find a better option than a hex head, but I like the "free" top hat spot lights

See the wires to the switch towers light? Above..............^^^^

This might be a pump, treatment & filter house for spring water coming from above the mine and ...... so on, and so on. My plans change.

I need a non-G scale ladder huh?![]()

(everything works, weather vane & mill fan, level gauge, insection hatch, slide spout).

I care more for easy detailing than scale. I did build it fit either really)

Progmess. (NO HARM WAS DONE TO ANY TIN PLATE IN CREATING THE SWITCH TOWER OR DINER!![]() )

)

(The Milkmans here)

Yep its lit. That glass will be the roof on a small veggi greenhouse kept by the proprietor.(a halogen floor lamps bulb cover.)

I'm going to "steam the windows" but in masking goo, write on a couple panes near the window seats. Like kids finger doodling as they wait. Maybe a couple in love has added their own arrow and heart shaped target?![]()

Attachments

I did not feel inspiration for much housework today so I spent about an hour trying to improve my results making evergreen trees. I used some jute and it worked OK but not great yet. I have to color the jute on the 4 trees I made. I might try dying them.

The Polar Gi-Raffe Express Berkshire is now cowcatchered!

The former Southern pilot and GX prepped for combining. Note that the little plugs on the Berkshire aft of the former cowcatcher have been pulled.

Test fit with rubber bands.

Pilot attached with brass screws.

A piece of stripwood holds the brass screws firm.

Remember, SCROUNGE!

Mitch

Attachments

Attachments

Attachments

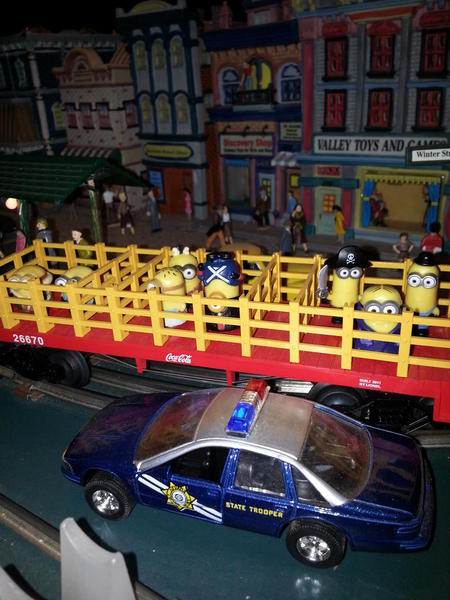

Did some cleaning in the basement and finished the basic installation of the Cruise Light on my diesel (Conventional works, but don't have TMCC to test that out). Low and behold, a new building popped up!

Wait...what's going on at the platform? Invasion from space!

The minions are battling it out. Hopefully it doesn't impact ice cream sales!

Attachments

Waiting to show the layout to visitors. I'll post comments and pics later.

Art

I only had about 15 minutes after I got up this morning before we left for kids house, I am spending some time with my new grand daughter and hope to get another wall finished on shelf layout later tonight, might even mark where the ceiling brackets will got for bridge crossing.

I spent a couple hours yesterday weathering freight cars, two cabooses, and a Docksider steamer. Also weathered a 1953 Chevy garbage truck. Big fun!!

Today I spent severe hours doing scenery work on the Patsburg commuter rail station, posting signs on an adjacent building, and doing some ballast work. Took some pics of the weathered rolling stock, and garbage truck. Will put them up on the OGR Forum in the next day or so.

Of course I also ran some trains too ![]() A Baltimore and Annapolis end cab switcher pulling a mixed freight, and a Western Maryland H7 consolidated pulling a 3 car passenger consist of MTH Premier Western Maryland cars - baggage, RPO, and coach.

A Baltimore and Annapolis end cab switcher pulling a mixed freight, and a Western Maryland H7 consolidated pulling a 3 car passenger consist of MTH Premier Western Maryland cars - baggage, RPO, and coach.

Not much accomplished lately, but today I got the sides cut out of styrene for the

tender for #60 (which loco kitbash has been done for a month). I am looking for a

chassis for it before I do much more on it. Other projects awaiting parts are a steam

coach and a feed mill kitbash. I also hope to do a much longer version of a gas electric on an Industrial Rail streetcar chassis (lengthened), similar to the short one

I posted on here. Will probably use Walthers gas electric kit parts for it, too, although

I also have parts from an American Standard Car Co. kit. (just had a thought...I have

a LaBelle kit for a Rio Grande gas electric, one the Grande did in house with kits railroads used to be able to get from two Wisconsin suppliers...THAT is what I should use the IR chassis for!) (I don't think the Grande had much better luck with that car

than they did with the Prospector...I hope I do)

Hello everyone. Well today O did some more painting of the breezeway ceiling which has the 1st coat . I also cleaned the garage up wear there is no more junk piled up on the tracks. Well its been just over a month since I started and I know it will take some more time . One thing I am wondering about is painting the floor in the breezeway. How many of you have used Rust-Oleum Epoxy Shield paint for this purpose ?

Attachments

Moving 1936, Electrical cables.

My house was built in 1936, moving the cables from the 1936 fuse box, in the kitchen to the Electrical Panel in the Train Room. Also removing wall paper.

Gary • Cheers from The Detroit & Mackinac Railway

* Click on each photo to enlarge......

Attachments

This triple track curve needs to be finished so that the next time Patrick comes over, we can put on the Roseville deck. I painted the track the other day.

Today is ballast day, the first of many!

My weapon of choice, a simple 4" paint brush. I've had this brush for 40 years. Not only is the bristle end good for spreading and placing the ballast, but the handle is perfect for shaping the "ditch" profile.

It seems that whenever the subject of ballasting comes up, Dewey Trogdon suggests the use of the squeeze bottle. He uses cheap ketchup and mustard sets. I happened to have a couple of clear ones in my never ending junk pile. I've tried spray bottles and even a turkey baster. I like the squeeze bottle method. The glue goes right where you want it. Thanks Dewey.

The 2' test section. I still have to spread a little more ballast, but I wanted to see how this was going to turn out.

I may have to thin the mix a little, I did about 1/3 glue, and it had the thickness of maple syrup, not milk.

Joe Wednesday, Matt next Sunday, still working on a day for Patrick, and Jon MIA. I'll just keep chuggin along.![]()

Attachments

Wow! Eliot it is exciting to see ballast going down. It looks great!

Art

Been tackling a bunch of minor jobs now that all electrical and insulating is finished, fingers crossed. The final electrical check passed with flying colors. at least I haven't smelled anything burning yet. I'm happy to report that temperatures upstairs during these past few sweltering days are now better than tolerable, although A/C will definitely be needed above 90F.

Firing up this tube tuner/amp was a diversion from the mundane task of room construction. It once powered one of those aircraft carrier sized '60's consoles, soon to be a built in trainroom feature.

Electrohome no longer exists but this one still delivers crisp clean sound and deep bass when mated to decent speakers. An example of what manufacturers did by pulling out all the stops on tube tech right before the move to solid state. Also doubles as a space heater.

Bruce,

Its even older than mine! Yes, it will make a nice heater for the winter!

Wow! Eliot it is exciting to see ballast going down. It looks great!

Art

Thanks Art, it is exciting. My mind keeps projecting the ballast around the upper deck. I just have to carve the profile along the mains first. <sigh> I've got too many irons in the fire.![]()

Had visitors over yesterday afternoon, one of which was a big HO train guy. Ran a few trains and talked about the layout. Everything ran perfectly for a change.

Then went out to eat at the Bull Moose restaurant, my favorite train theme place to eat locally. After a great meal, I jokingly complained to the server that we had not seen any real trains while we were here and before I had finished my sentence, the Amtrak Illinois Zephyr blasted by. Then on the way back to my house we drove past a section of the BNSF mainline and didn't see any trains.

So I went the back way and as we approached the last RR crossing before we got home, the crossing signals came on and we were first in line to watch a 100 plus car silica sand unit train pass us. Their were two BNSF engines on the front and two more pushing on the rear. after it passed, we hurried home and went the crossing in our subdivision and saw it pass again and everyone took videos of it going by.

A great train day!

Art

Elliot; the ballasted section looks good. I remember a previous photo you posted of bags of ballast. Couldn't find it. Where did you get the ballast?

Elliot; the ballasted section looks good. I remember a previous photo you posted of bags of ballast. Couldn't find it. Where did you get the ballast?

I would like to know that too. I have a lot of it coming up as well. Not nearly as much as you do, but a lot for me.

Art

It is supposed to be very hot for the next two days, so I need to spend some time in the cool basement working on the layout. And I must wash the car today so it's clean for layout tours tomorrow.

Plan to paint more already installed track and switches. Must remember to cover the return air ducts from the basement into the air conditioner so I don't drive us out of the house this time. ![]()

Art

Elliot, what size dump truck (1to1) hauled in your ballast material. Must be a huge pile in the driveway. ![]() Photos please.

Photos please.

This triple track curve needs to be finished so that the next time Patrick comes over, we can put on the Roseville deck. I painted the track the other day.

Today is ballast day, the first of many!

My weapon of choice, a simple 4" paint brush. I've had this brush for 40 years. Not only is the bristle end good for spreading and placing the ballast, but the handle is perfect for shaping the "ditch" profile.

It seems that whenever the subject of ballasting comes up, Dewey Trogdon suggests the use of the squeeze bottle. He uses cheap ketchup and mustard sets. I happened to have a couple of clear ones in my never ending junk pile. I've tried spray bottles and even a turkey baster. I like the squeeze bottle method. The glue goes right where you want it. Thanks Dewey.

The 2' test section. I still have to spread a little more ballast, but I wanted to see how this was going to turn out.

I may have to thin the mix a little, I did about 1/3 glue, and it had the thickness of maple syrup, not milk.

Joe Wednesday, Matt next Sunday, still working on a day for Patrick, and Jon MIA. I'll just keep chuggin along.![]()

Technically, I'm not supposed to divulge my source for the ballast. My guy at the quarry swore me to secrecy.

This is a product known as head lap or roofing granules, and normally they don't sell it to the public, it goes directly to the shingle manufacturers. I was able to sweet talk my way into getting a good sized stash by contributing to their coffee fund.

What you are looking at is 17, 50 pound "sample" bags. The eighteenth is in a 5 gallon bucket that I'm working from. It took me 3 trips to get the nearly half ton.

This quarry also produces ballast for the railroads, so it is hard to get more prototypical than that.

Attachments

Great find Elliot! Very smart solution for a HUGE NEED.

I took time out working on the station to actually run trains for a few minutes I hadn't been up there in about a month so it was time. here is the results of that session ![]()

I did a total of 7 or 8 small videos not going to post them all here.

Elliot - I have been secretly thinking that I wanted to get a pickup truck. This could be another reason I need one. ![]()

Great solution and thanks for sharing.

Art

This afternoon I applied plaster to the bare plywood between the tracks to the station. Once that dries I can color it and then lay down ballast on the sidings to the station. I started adding ground foam to the cliff I have near the bridge. Shortly I will be adding some trees and shrubs to that cliff...............Paul

Elliot - I have been secretly thinking that I wanted to get a pickup truck. This could be another reason I need one. ![]()

Great solution and thanks for sharing.

Art

Yeah Art, I've been driving a pick up as a second vehicle for over 20 years. They are very handy especially for those Menards runs to grab layout materials. However, the last couple years, my orders have been so large I've just had them deliver those.

The delivery guy has been working at my local store since I built the house 15 years ago, and remembers me from back then. Now that he has been bringing layout stuff, I always invite him in to check out the progress. He likes delivering here.![]()

I've known about using roofing granules for ballast since the late 80's. The Twin Cities Model Railroad Museum (2 rail club) used them. My problem was I didn't have access to their source. It was actually one of the many ballast topics here on the forum a couple years ago, when someone used the magic word "quarry", that I put 2 and 2 together.

JACKPOT!!!![]()

![]()

Elliot; thank you for your response. ![]()

Check with your local quarry. Not every plant makes roofing granules, but you may get lucky and have the plant close by.

Eliot great progress. It really looks good. 900 pounds of ballast.. Wow!

If anyone needs a source of free sand, we are at Hatteras and found plenty this AM while clamming (got two 5 gallon buckets of clams). The sand comes with clam, oyster, and scallop, shells and traces of mud that can be washed out if desired.

Now we are getting ready to restart construction on the yacht sales office and will use the sand as basic material for the road in Wanchese/Manteo where the sales office will be located. The shells will be crushed as a base and the mud will remain so that the look is authentic.

About half of the interior is complete and as soon as that is done, we will attach the roof, etc. Weathering will be minimal (have to do the roof... you can't hide from the seagulls) because this part of town is an historic area and is well maintained.

Attachments

Why doesn't someone offer to clean a roofers truck bed for them![]() .

.

Please take a camera, I want to see their face as you ask.![]()

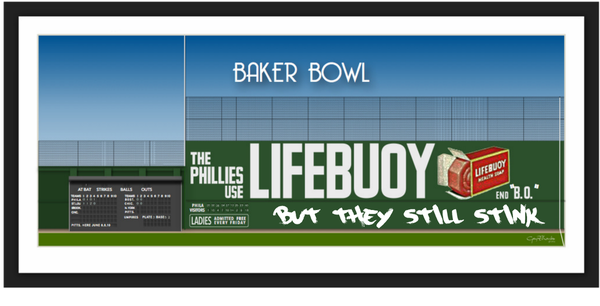

Kept working on my baseball field....got light towers installed and wired, chain link fence made and installed, grass beyond outfield fence put in. Starting planning next few steps...scoreboard, dugouts, backstop. Will start on those in next couple of days.

Attachments

I finally just "TOOK" time to finish trimming and leveling 3 walls of shelves, now I need to shave the edge of one and then paint it all, after that, tomorrow or the next time I get on it, I can screw it off and start tackling the bridge section, it feels good to finally get close on part of it, I even test curved some track on the outside corner, looks like it will be 054 and 048 if my samples are correct.

Attachments

Bryan, the baseball field is looking real good. The pics make it look like the real thing. I can smell the hotdogs...............Paul

This morning I got the yard work out of the way before it got humid. With the plaster down from yesterday I applied the first coat of earth color. Later today I will put on the second coat. Pics of the progress working my way to the back of the station area...........Paul

Attachments

Attachments

that is way cool

Visited another very cool layout in the area this morning with friends and family. Great day!

Art

Bryan this looks really good. Don't see any Dodger blue but Ohio is a long way from LA.

Please keep posting.

Covering up all that pink stuff is now in full swing. With the hip walls all paneled and almost completely primed, the job at hand is installing the thin 4' X 8' sheets of hardboard.

Down at this end you pretty much get the full effect of curving the hardboard in corners. This will help keep the layout background somewhat seamless. Adjoining sheets overlap each other for added support.

The cedar lumber that overlaps and supports the hardboard edges is a failed experiment. Some other form of finishing treatment will be needed here. The shelf top in back and off to the right will be future staging yard area, with as much of it left open as possible ( maybe half ) for easy access.

And finally the view from the other end. The overlapped seams are plainly visible now. I plan to snug the sheets together using structural adhesive. If you look close you'll see no nails or screws fastening sheets to the rafters. Basically, the curvature holds them tight against the studs and with enough rigidity that bulging insulation only bows them slightly at the upper edges. Hence those longitudinal boards take care of the slight deformation

At this rate I suspect layout commencement will begin on schedule in September.

Bruce

A new commuter station opened in Patsburg on Monday July 27. Heres a pic of the folks gathering and waiting to catch the first train out.

Attachments

I spent yesterday doing a bunch of stuff getting ready for Patrick, including more ballasting and some painting. As I had just finished painting the bottom of the Roseville deck black, and was going to put the lid back on the can. Unfortunately, the can was right under the duck under.

THWACK... OWWWW!!!

I walked into that thing so hard, I bounced off it, and landed on my butt. No serious damage, but it was kind of scary. There's no actual bump, but there is a sore spot. Imagine that.

A great afternoon with Patrick today. It started off with Patrick finishing off the Bondo on that pesky section of backdrop, while I continued to work on the ballast. Yesterday, I hung a couple sections of fascia, but today we went crazy and put up another 8. That's a total of 80'!

All of this is just tacked in place. Jon will be here on Friday and finish securing it. It runs from Shoreham on the left, around the curve through University on the right...

past what I have nicknamed the "narrows" (the tightest spot of the aisle)...

around Northtown curve...

past the bowl tracks and all the way down to the hump.

When we finished that, Patrick sanded and primed the backdrop.

While he was doing that, I was cleaning the glue off the rails, so we could install the Roseville deck.

We had to add scraps of 1/4" Masonite to get the necessary clearance.

Tight but adequate.

In the clear!![]()

Finally, there's this thing. This retaining wall is another "mall remnant". Over the last 22 years I came so close to throwing it in the trash so many times, but yet I hung onto it.

It's just a bunch of old GarGraves ties glued onto a Masonite superstructure. But ever since I put it up there on the layout, people have said they really liked it, even though I'm not overly fond of it. With a little modification and some freshening up, I'll make it work, and maybe even like it again. There is going to be an oil loading facility up there, with 2 tracks and plenty of tank cars.

Joe tomorrow, Jon Friday and Matt Sunday. Thursday I'll probably get back to that ladder I was working on, and Saturday I have to get all that fascia filled and painted for Matt to do more manual switch throws. Busy, busy, busy!

Attachments

Hi Elliot - You always do an excellent job with the photography on your post.

The captions bring it all together. The layout looks great.

Gary

• Cheers from The Detroit & Mackinac Railway

Elliot; It seems like you guys are making some real progress. ![]()

Doing two posts today. This one is for Bryan who is doing the ball diamond. I ran into him at a train get together last night and he wanted some pics of the general layout because it had been many years since he saw it last. So here there are Bryan. Excuse the chaos. Been working on the layout............Paul

Attachments

Bruce,

The attic is looking more like a layout room all the time. The curved ceiling joints are cool!

Bryan,

The ball field is great!

After taking pics of the layout I got back to work on the station area. I was happy with the second coat of earth color so I sprinkled down some grass foam. Then I added ballast to the tracks. Now I will place the station first drilling some holes to run the wires from it under the table. Didn't finish the one track in front of the station. I ran out of plaster and didn't want to make another batch up till I had a place to use it all. .........Paul

Attachments

Jim and I were able to spend a couple hours on the layout last night after he got off work. We were able to cut the right end yard switch into the mainline. Then we added the curve tracks for the yard lead and added the first switch at the right hand end of the ladder which finished the first yard through track. Have some issues to resolve now by doing some major surgery of the next switch to allow 4" spacing instead of the stock 5 1/2" spacing. Will post some pictures later this evening.

Art

Kept working on my baseball field....got light towers installed and wired, chain link fence made and installed, grass beyond outfield fence put in. Starting planning next few steps...scoreboard, dugouts, backstop. Will start on those in next couple of days.

I got the scoreboard covered!

Mitch

Attachments

Bruce,

The attic is looking more like a layout room all the time. The curved ceiling joints are cool!

Thanks Mark,

It feels great to be nearing the end of the hard slugging and on to more detailed work. I'm more than half way finished applying the white melamine masonite, which is going up far easier than I expected. I often wonder what type of miserable job it would be to drywall the ceiling instead. The imaginative use of construction materials ( toot'n my own whistle ) has saved money, time and most importantly my back. Heat is the only obstacle holding me back at the moment. Under those circumstances I tackle something less strenuous like these shelves.

Bruce

Thanks for the overview pictures really helps visualize everything now. Layout is looking awesome and definitetly looks different from the last time I saw it. Keep up the great work.

Hello Everyone. Hear is a video of the progress I have made recently.https://youtu.be/yP37ZWdmePU

Scot - You have made a lot of progress! That should be very encouraging. I believe and hope that after you finish painting and get the bench work exposed without the clutter than you will be able to continue make a lot of headway. Thanks for the video up date and good luck.

Art

Doing some rebuilding of a Plasticville city hall to more closely resemble the one in my hometown.

Adding a base to raise it about 6' and adding a basement entrance, modified the roof a bit, and will be putting in aluminum framed glass doors fore and aft.

My layout is just a loop of O-72 on the carpet of the guest bedroom right now, but I did add Legacy to it today.

My layout is just a loop of O-72 on the carpet of the guest bedroom right now, but I did add Legacy to it today.

A table doesn't have to be the answer.

Carpet is very quiet in comparison to any table layout.

I had 0-27 on the carpet for a literal lifetime. At least once a year my whole life, there has been track on the floor somewhere.

All tracks up and running today, I have 7 lines above the waist. But I still put track on the floor, from time, to time.![]()

I never bent one on the carpet in a derail.![]()

I stumbled and stepped on a plastic tender though![]() .

.

I'm going to toss a throw rug up on a table; just for my old stuff; just for laughs; some day.

But seriously

Scot - You have made a lot of progress! That should be very encouraging. I believe and hope that after you finish painting and get the bench work exposed without the clutter than you will be able to continue make a lot of headway. Thanks for the video up date and good luck.

Art

Scot,

I agree with Art's statement. Room preparation is important before getting too far. It is easier to cover the table with plastic now than later. I haven't said it before, but I really like your enclosed breezeway for a layout room. In the daytime you will have plenty of light, and it was practical to cut a hole in the wall to extend into the garage. I agree, thanks for the video!

I wondered what track you had in the garage. Thanks for the look see. It is looking good!

been playing more than working the past few days. haven't touched the layout. but ran trains, haven't touched the station but ran trains yea running trains has been more fun the past 2 days. here's another video my note 4 sitting in the railing on a Lionel sd40t-2 LOL

Absolutely nothing. While my boy has been running trains, more than likely I won't find the time to get down there to do anything until Oct.