Thought I’d start a post of my conversion of a Williams Scale 44ton diesel to Blunani. Since I’m an electronics neophyte I thought others out there might learn from my experience and possibly increase the interest in what Blunami offers. This will take a few months to finish since I don’t have a dedicated work area, yet.

Thought I’d start a post of my conversion of a Williams Scale 44ton diesel to Blunani. Since I’m an electronics neophyte I thought others out there might learn from my experience and possibly increase the interest in what Blunami offers. This will take a few months to finish since I don’t have a dedicated work area, yet.

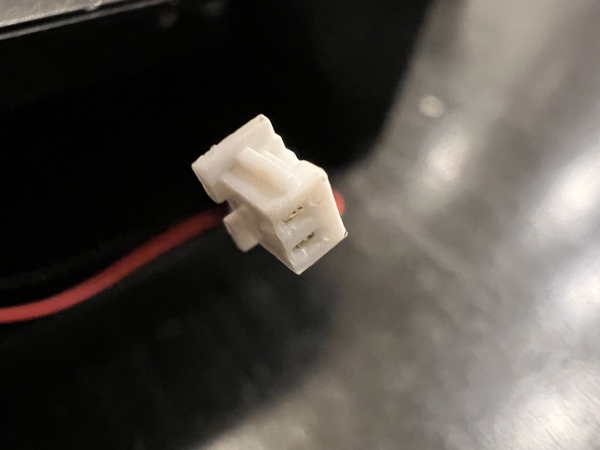

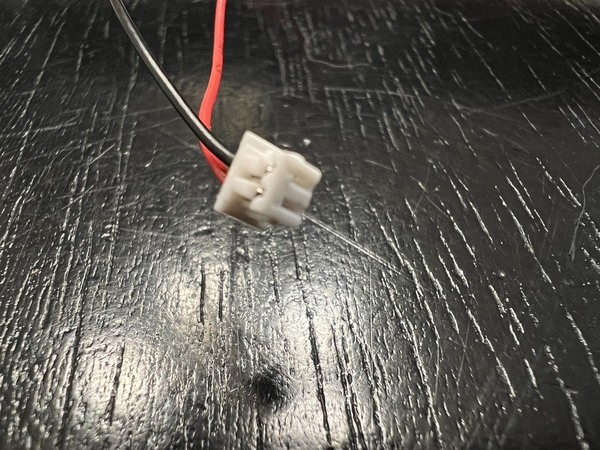

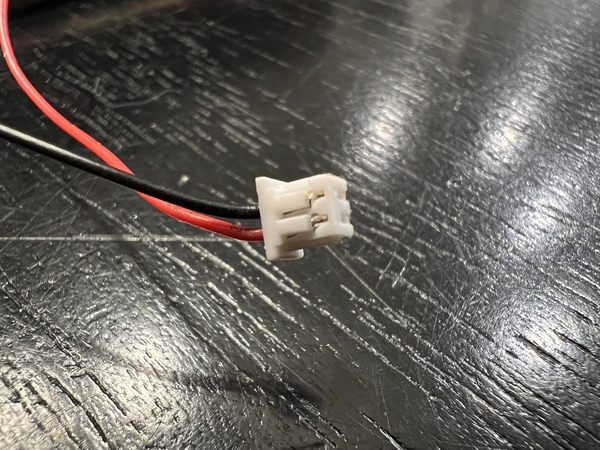

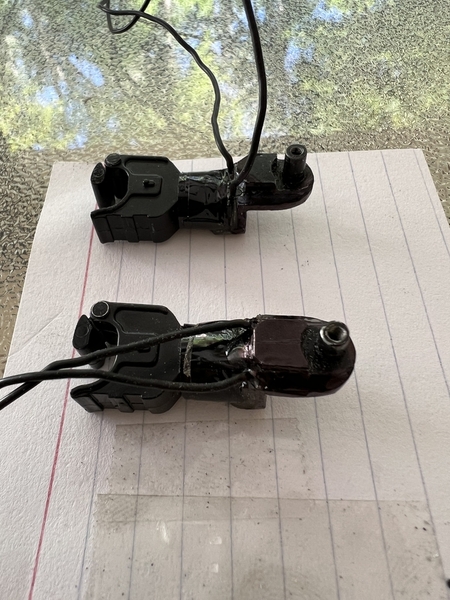

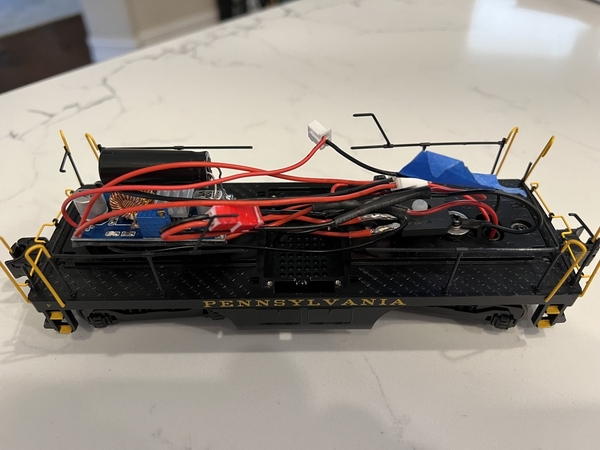

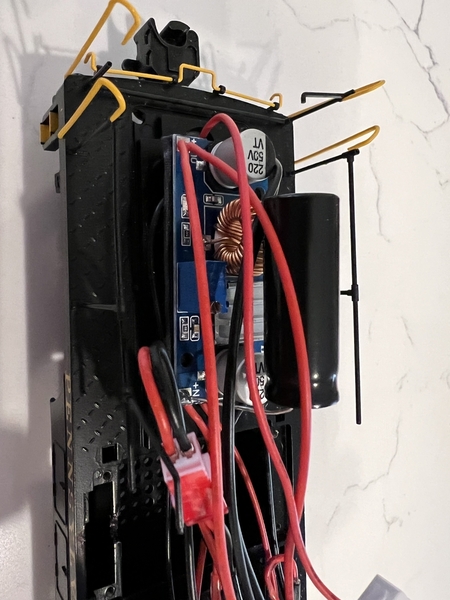

This Blunami conversion will use the track as a source for power as this engine will be given to my 5 yr old grandson. I have stripped the engine of the original electronics and cut off one of the standoffs to provide more room. The motors have been wired in series to slow the engine down a bit. I have completed and tested the build of the AC/DC conversion assy using the items suggested by KARLDL. The chassis was placed on the track, power was provided by a 180 brick and the DC/DC converter was adjusted to 18vlt output. I can tell already that wire management is going to an issue! Next step will be the testing of the Blunami 2200 module prior to adding connectors and installing. Does anyone know what tiny connector is used on the Williams speaker?

Phase-2 will be population and installation of the electronic coupler board designed by KARLDL and modifying Lionel trackmobile couplers to fit. Also thinking of adding lighting to the cab.

Up front I’d like to thank KARLDL, gunrunnerJohn, and Ron045 for providing technical data, component recommendations, and answering all my dumb questions!