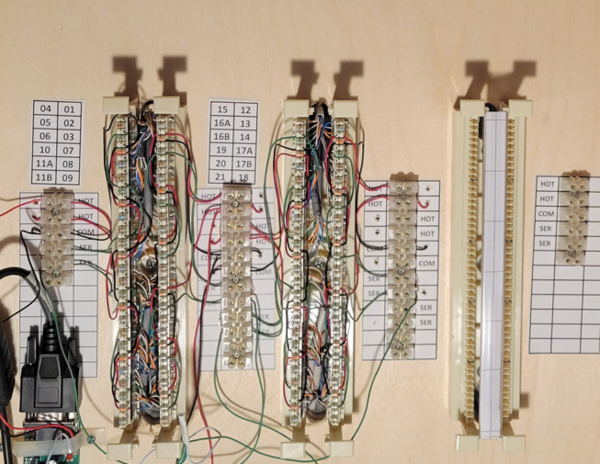

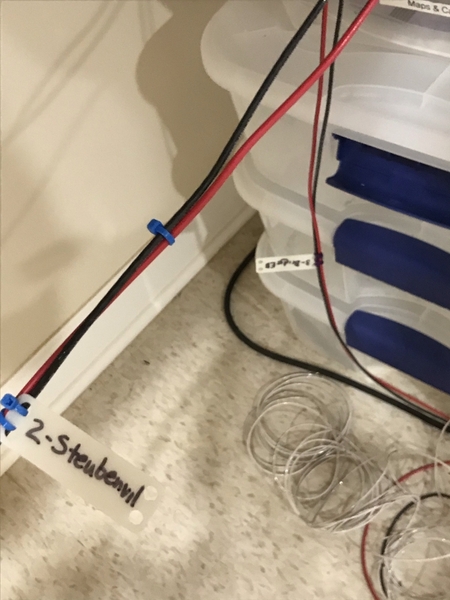

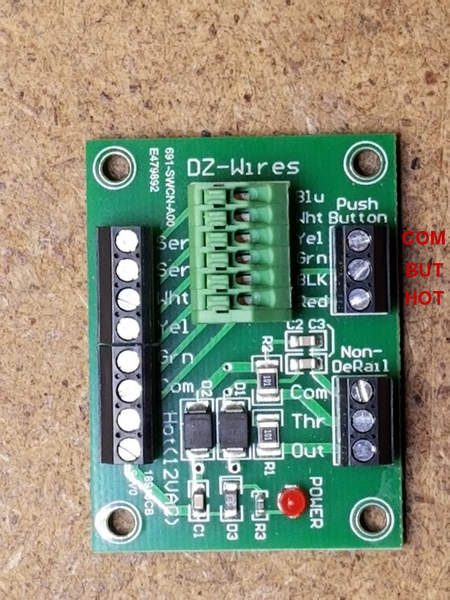

Is it just my layout or do all layouts require this much wire? I have been wiring the rails on my 16x17 layout and looking ahead is an eye-opener. I have 8 electrical blocks going into 3 TIUs. Each block needs--oh what--pick a number--say 6 drops for the center rail, and six for the outer rail (the two outer rails being just wired together so they only need one wire), going to a junction box or TIU close to the block. Even under the best assumptions for distance, this is 12 wires totaling at least 100 feet times 8 blocks is 800 feet.

Now we add switch machines, LED and/or bulb lighting, signals and so on. It's easy to guess that my 16x17 foot layout could require 10,000 feet of wire! And how many connections? Whoa...

Don Merz

Gett

Gett