I am planning on using all Ross products because I have a fair amount of their track forming my loop layout. The switch thing does have me confused a great deal. The problem I have is equating the switch numbers (#4 for example), wye's and 3 ways to radius. For example, given a #4 turnout, will an 072 minimum radius locomotive pass through it? Given an 11 degree wye, will an 072 make it through? I was just told to stick with #11's by several people.

TL

All the numbered switches available in three rail O gauge including the entire Ross Premier line will handle locomotives requiring O-72.

An O-72 switch has a diverging route (the curved part) that is equal to a piece of O-72 curved track.

A numbered switch only has a curve on the diverging route between the points (the moving rails) and the frog (the angled crossing in the center of the switch which is plastic on Ross switches). Beyond the frog the diverging rails are straight. If the diverging route moves away from the through route 1 inch over 4 inches of travel you have a #4 switch. If the ratio is 1 inch for 6 inches of travel you have a #6 and so on. The curve between the points and the frog on a #4 or larger numbered switch is a broader curve than O-72.

Here is Ross's statement on that question.

Can my 072 engines run through a Regular switch?

Yes, with ease. The Regular (#100 and #101) is much more gradual than an 072. If you had to put a number on the curve in the regular it would be over 100" diameter.

The Ross 11 degree wye has a departure of only 5.5 degrees from the centerline. That makes it very gentle indeed. It is much broader than an O-72 curve.

Ross makes a # 10 switch. It is intended for sidings or crossovers on high speed main lines and would not be useful on a compact switching layout. No one makes a #11 O gauge switch.

I think it is an SD90 or DD40 that requires the 072. I know it is goofy but I have it and will only have this layout so I really want to run it.

The MTH SD90MAC only needs O-42. Their DD40, with its 4 axle trucks and greater length calls for O-72. When I said..

It can be a very enjoyable aspect of the hobby that makes us tackle 1:1 scale problems.

...you have one if you will be switching with a DD40. With numbered switches you will be OK radius wise. The MTH version has good speed control and remote couplers. But the length will limit its usefulness. It will cut down on the number of cars you can handle on many of your moves.

A real railroad crew would have flipped out if anyone gave them a DD40 as a road switcher.

I am going to go all manual throws so I do not think wiring should be that hard on the switches but some have even gone so far as to tell me to stay away from switches as the wiring is a pain even if manual throws are used. In 3 rail I thought it was as simple as providing common and poser to all three sides of the switch but I am told it is not that simple.

If someone told me to stay away from switches on a layout I would simply stay away from them!

Ross manual switches do not come with the center rails or the inside legs of the switches pre-wired together. You can easily wire them together or power them through the pins where they connect to other sections of track. There is nothing complicated about the wiring for a permanent layout. For the layout (actually two side by side layouts) you are looking at needing 15-20 power drops if you do not wire the switches for power.

The only way it might seem complicated is if you are coming from a carpet central world with only two wires to a lock-on.

If I am not taking the space now, should I plan for future expansion?

Absolutely! If you can think of your shelf switching layout as a module for a future larger layout you can add to your future enjoyment with continuous running, a yard for your local switch job to originate and terminate and more industries and scenery.

To be fair, there are not many 3 railers or even O scale people around my town so I could be getting some bad advice. I think I might have had analysis lead to paralysis. Coupled with the frustration it is kind of tough. That is why I joined the forum. So I appreciate your response and help.

You are in the right place here. Welcome aboard!

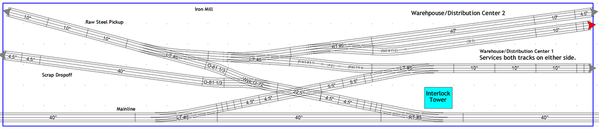

![]() I have a simple loop layout now but would like to get into the "switching" aspect of the hobby. I have done extensive "Googling and have found the Popular Timesaver and Inglenook type of layouts. Visited Carl Arendt's site http://www.carendt.com/microplans/index.html and such. All I can really come up with is variations on these Timesaver and Inglenook type plans. Two of my creations are attached below.

I have a simple loop layout now but would like to get into the "switching" aspect of the hobby. I have done extensive "Googling and have found the Popular Timesaver and Inglenook type of layouts. Visited Carl Arendt's site http://www.carendt.com/microplans/index.html and such. All I can really come up with is variations on these Timesaver and Inglenook type plans. Two of my creations are attached below.![]() so please do not be shy.

so please do not be shy.