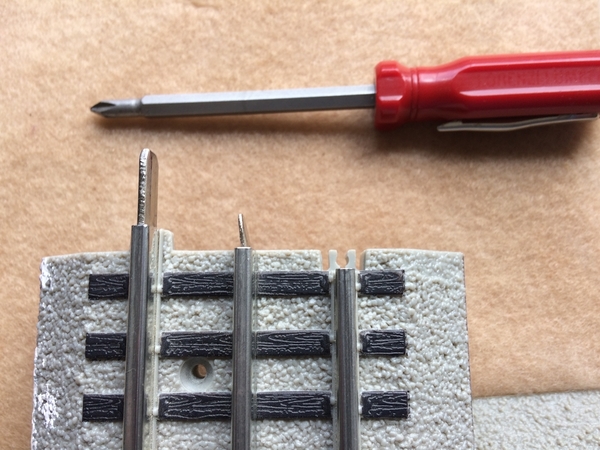

I like Fastrack but it has a couple design flaws that often lead to "dead" spots or even more sneaky "slow-down" spots. Lionel came up with the recommendation to laterally bend each center-rail pin to create a positive friction fit with the adjacent track pin/rail end.

Bend a few degrees to the left, towards the screwdriver tip in this pic. It takes a couple tries the first time because too much and it is impossible to join track pieces while too little doesn't address the problem.

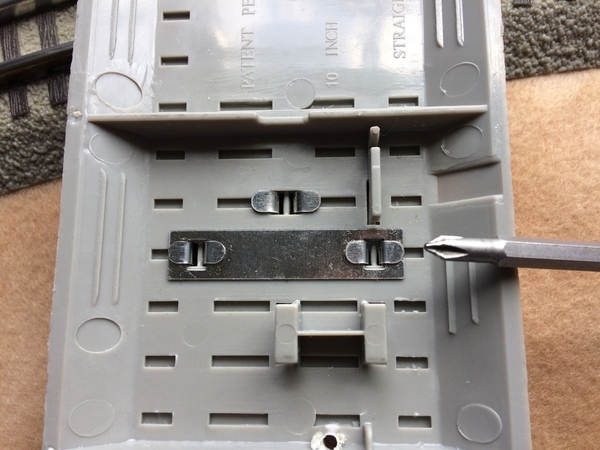

Under each track piece is a flat jumper between the outer rails which depends on a crimp-fit with tabs under the rails. Sometimes these are either loose from the factory or from vibration of trains running over the rails. Some people solder these connections.

Solder the tab to the plate.

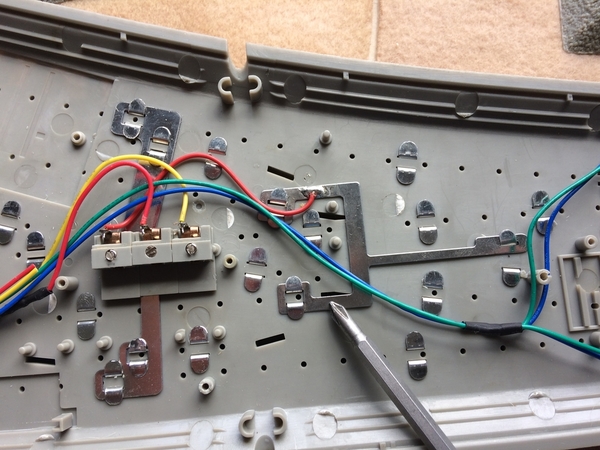

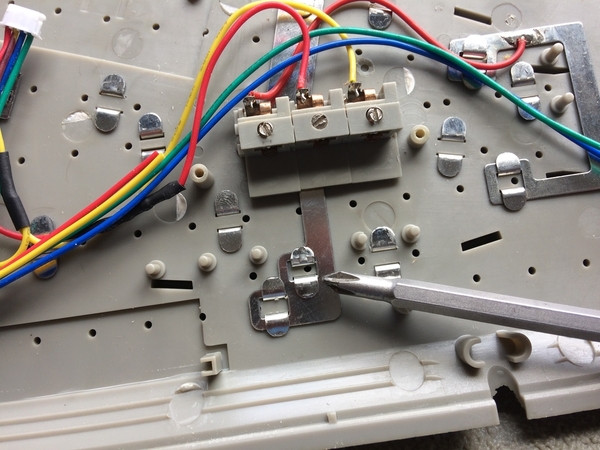

Fastrack track switches have similar jumpers and I plan to solder any that come up for maintenance.

This track switch has been parted out so most of the guts&wires are missing making it easy to see the jumpers.

There are four jumpers in an O72 switch,

Lew