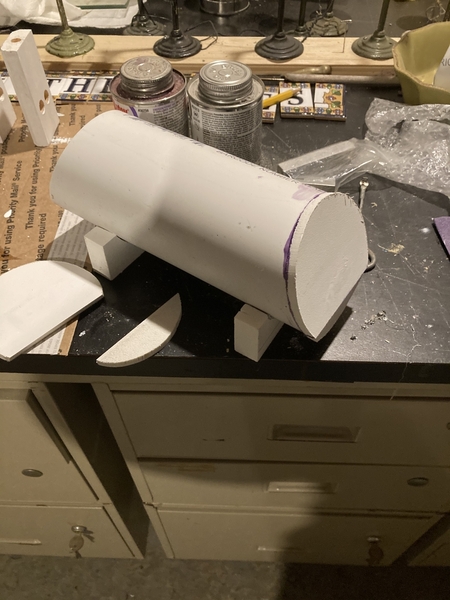

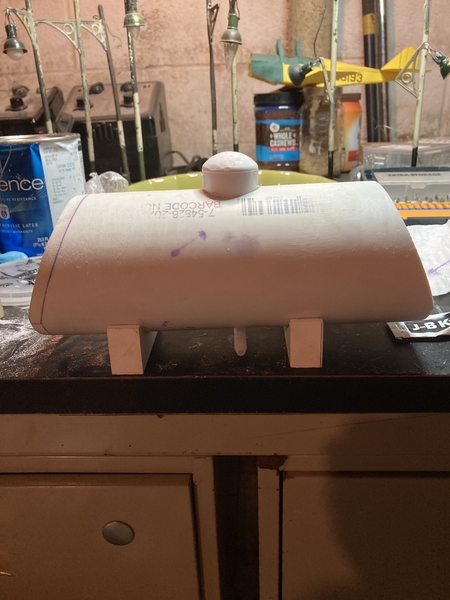

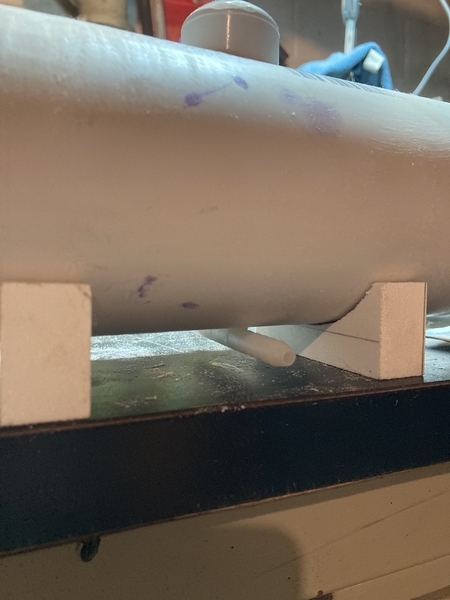

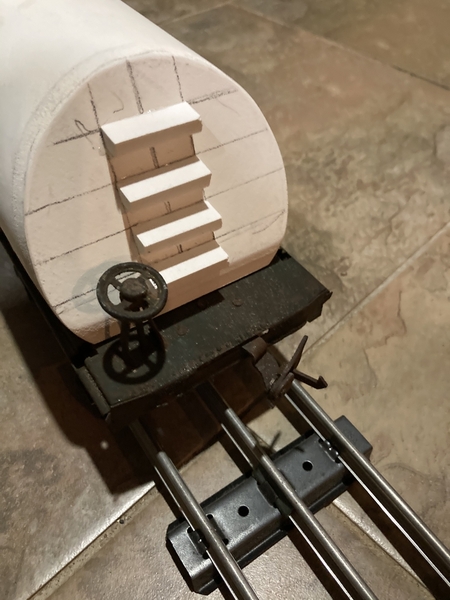

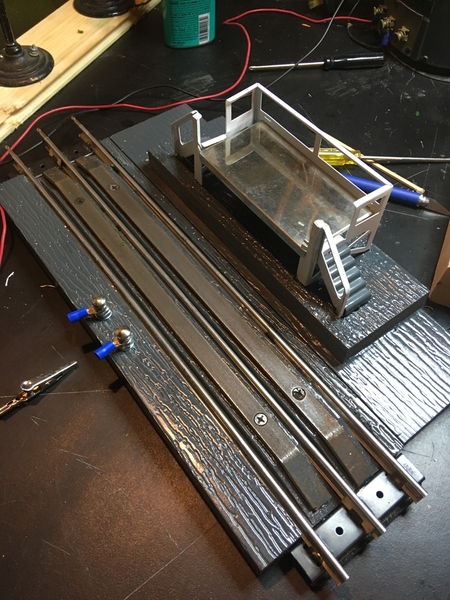

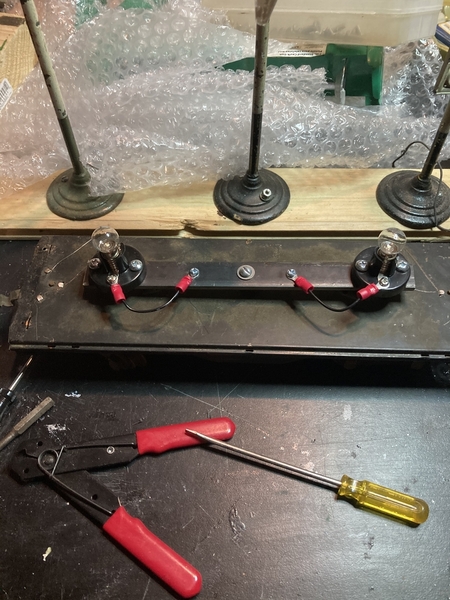

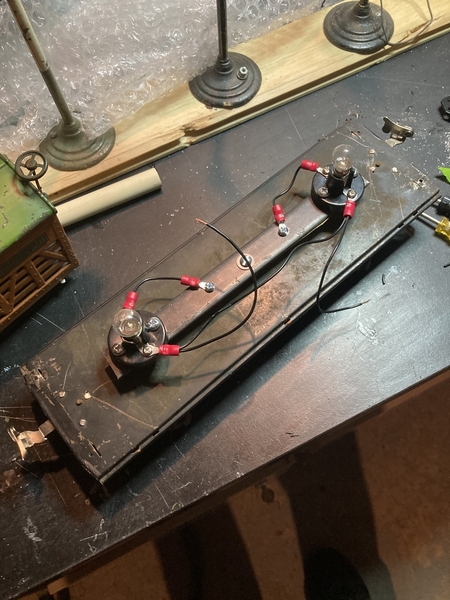

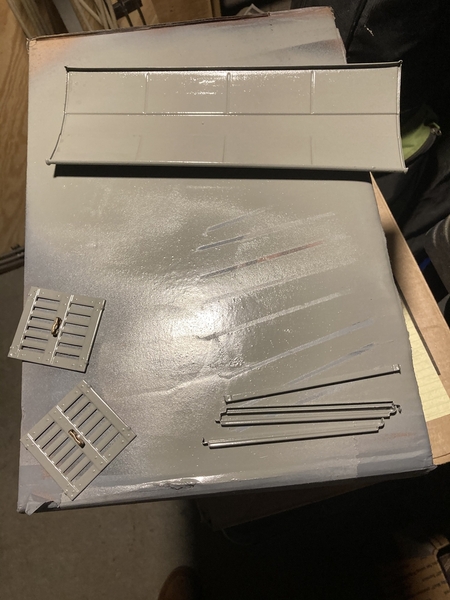

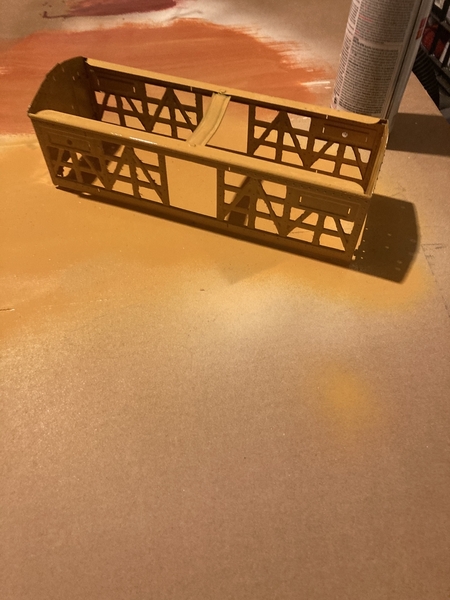

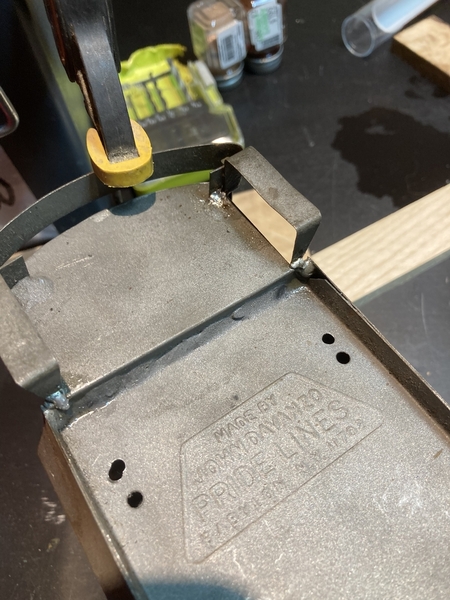

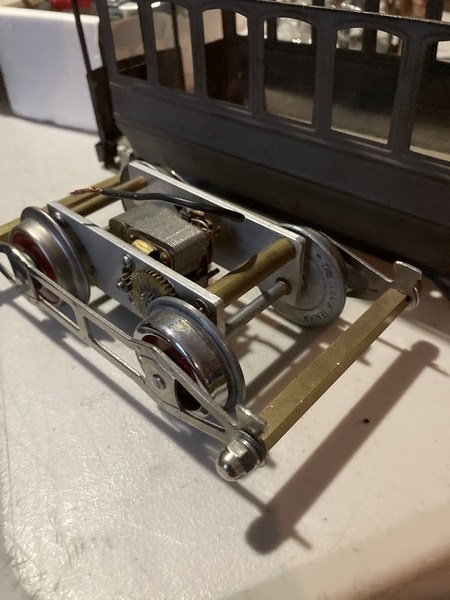

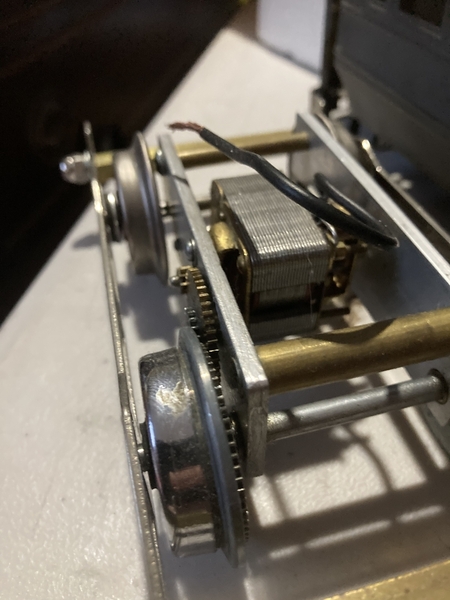

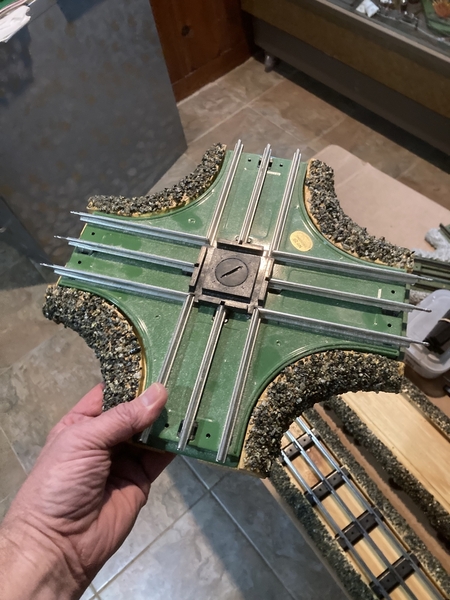

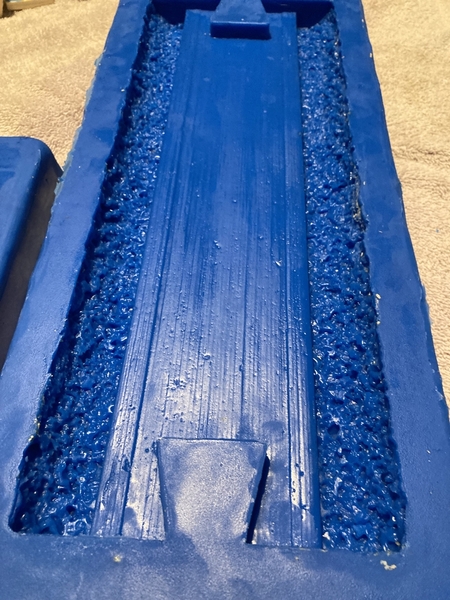

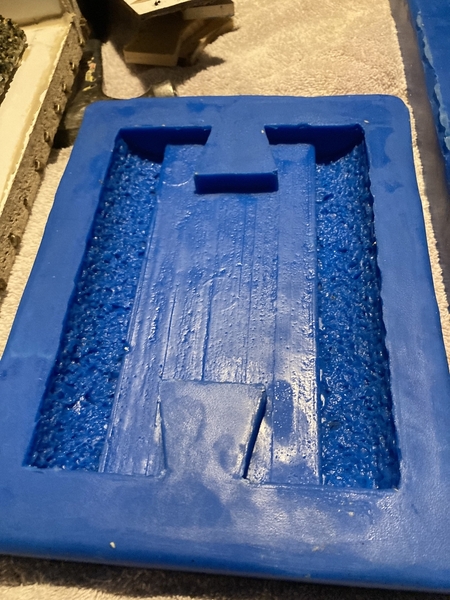

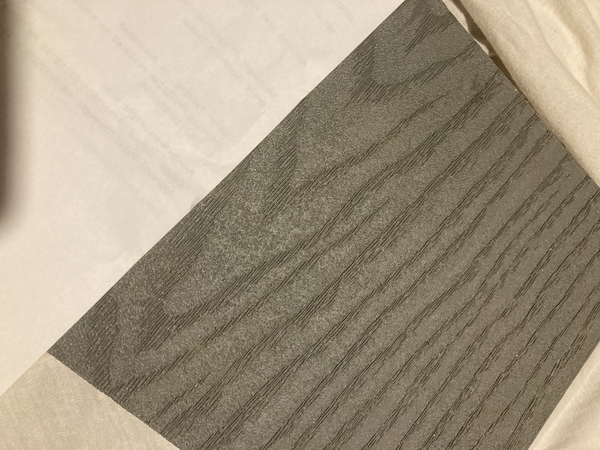

This is my latest project, its a Pride Lines reproduction of a Lionel#2 Trolley with a McCoy truck and an Ira Keeler drop in open frame motor. This is its first run ever and my puppy's first intro to trains. Now I will have to add a head light and a tail light, passengers,engineer, maybe a pantagraph or trolley pole, and some paint. If I add the pantagraph I can run it on my shop layout which has a live standard gauge catenary wire(rail). If I make a trolley pole I will make a trolley wire system like I saw at York in the orange hall. Either way it will be nice seeing it run from the over head wire/rail .

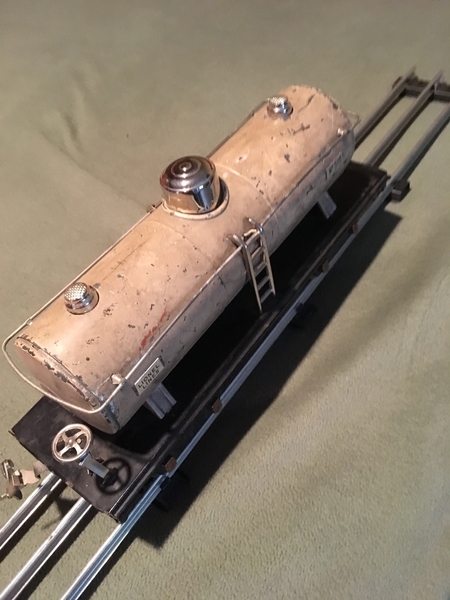

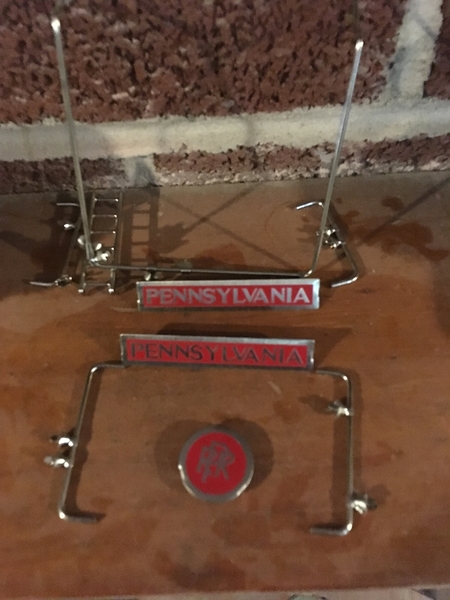

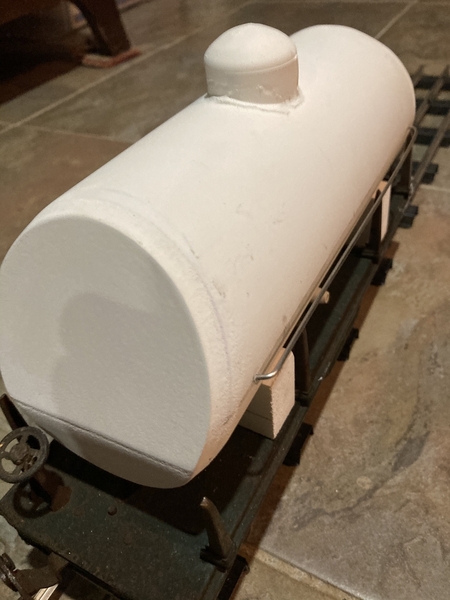

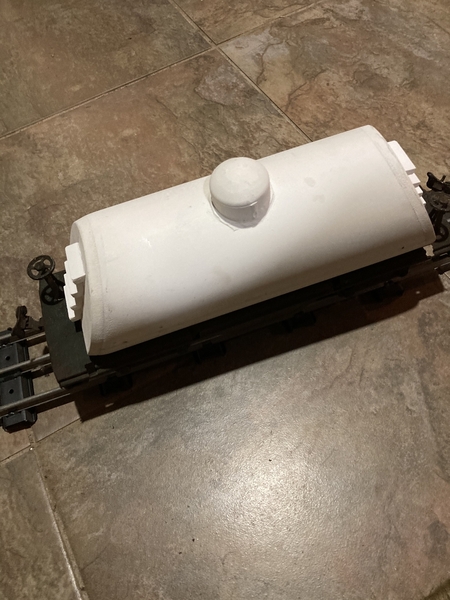

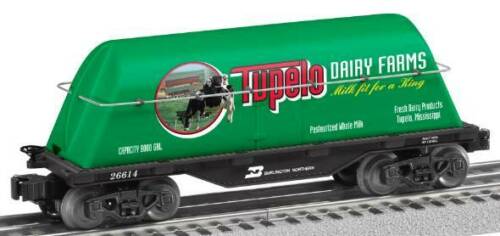

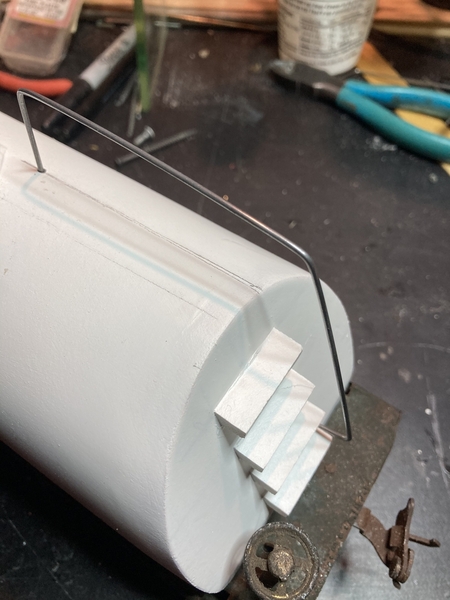

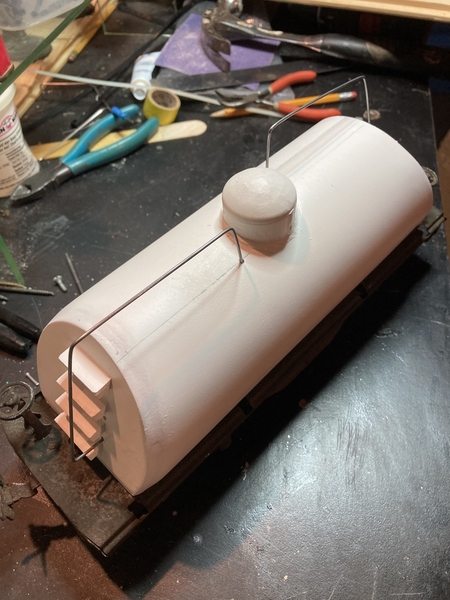

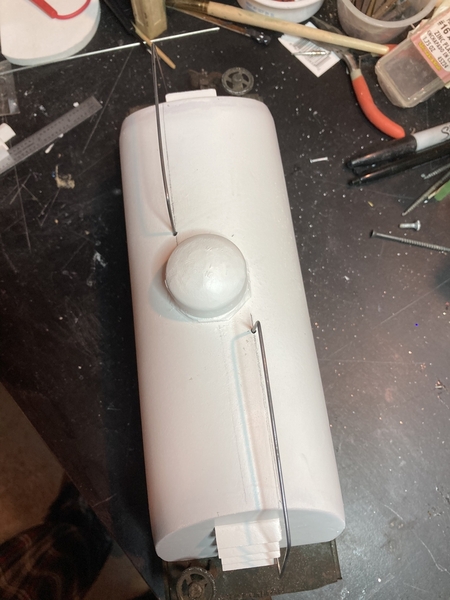

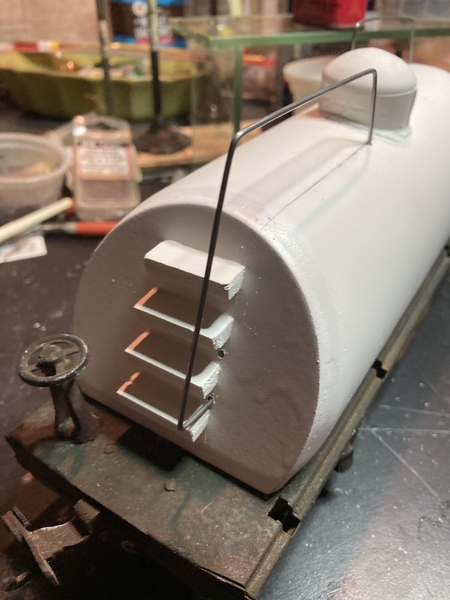

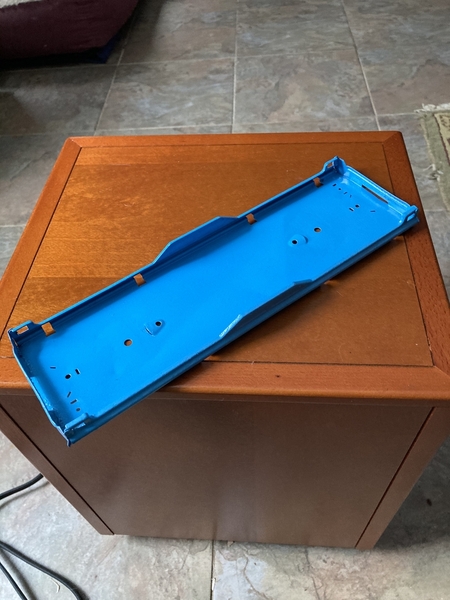

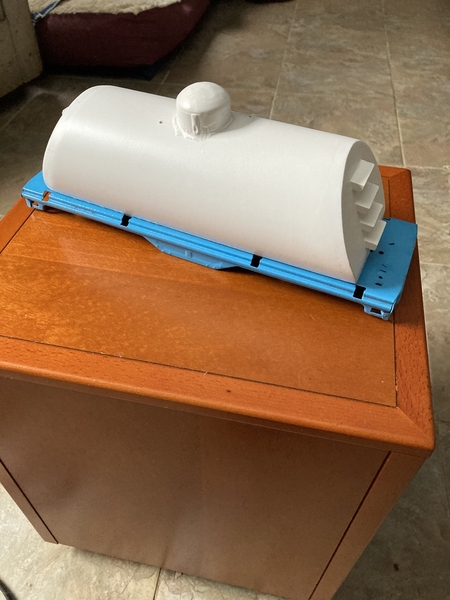

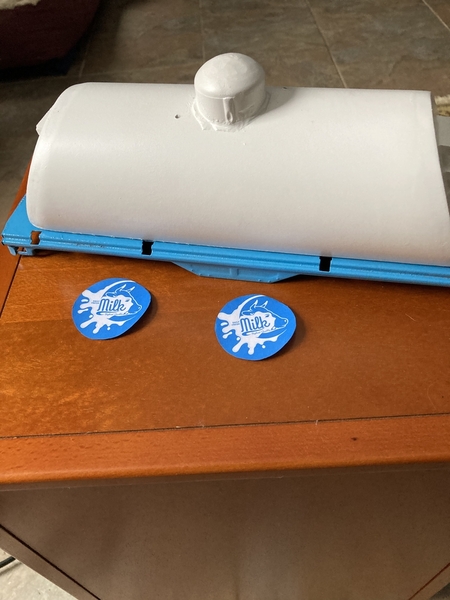

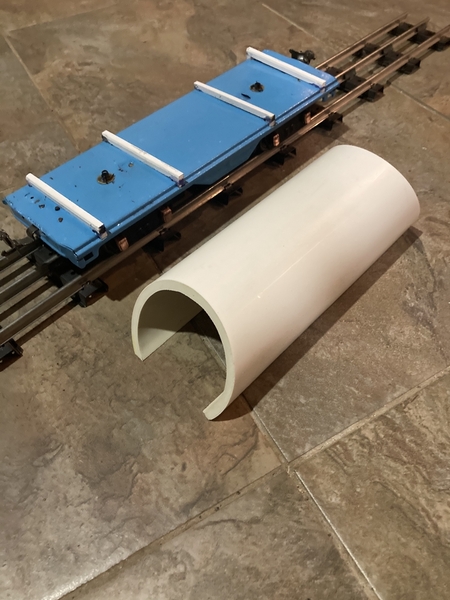

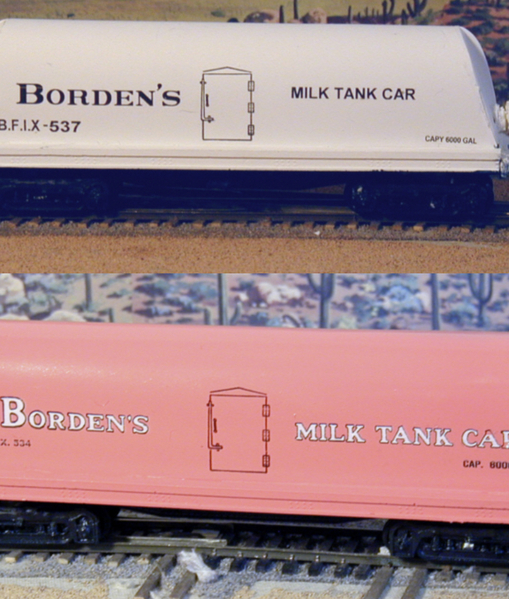

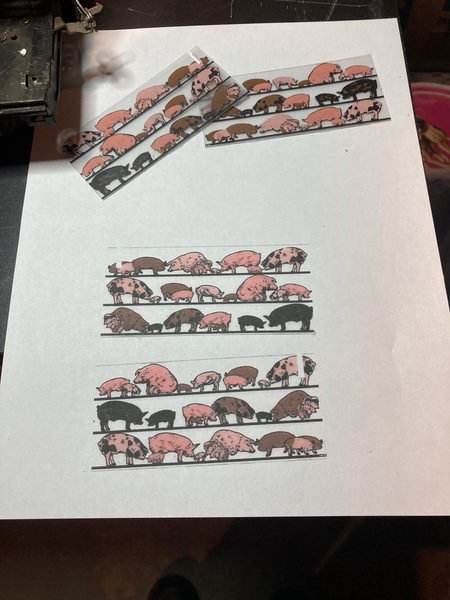

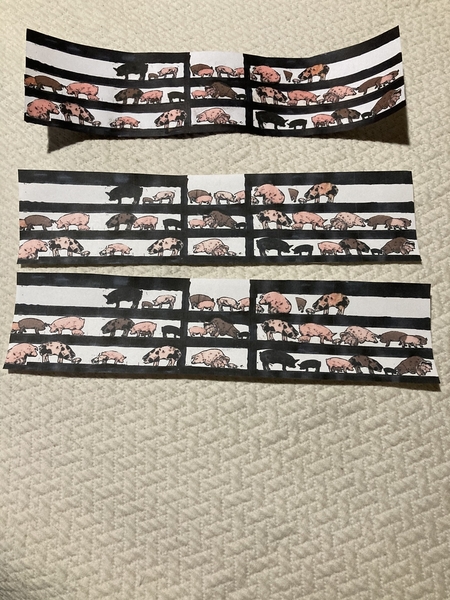

My other projects include: finding a pair of silver 512 badges for my gondola car, a silver center dome for my 515 tank car and a silver handrail for my 520 search light car. I also still have to find a photo of a drover to put in my lighted 513 poultry car that I made. Then maybe I can move onto the next standard gauge project! LOL