Here is a list of whats in the photos above.

1 165 magnetic crane

1 laser cut bridge ( painted yellow, bought at York )

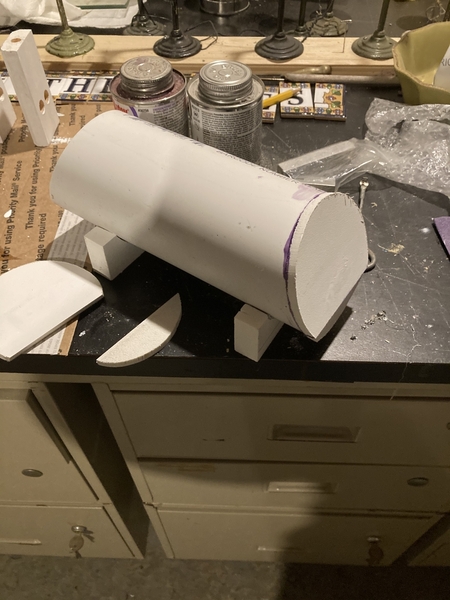

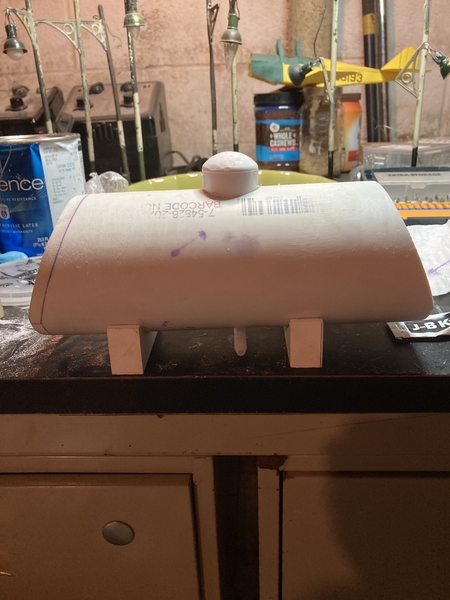

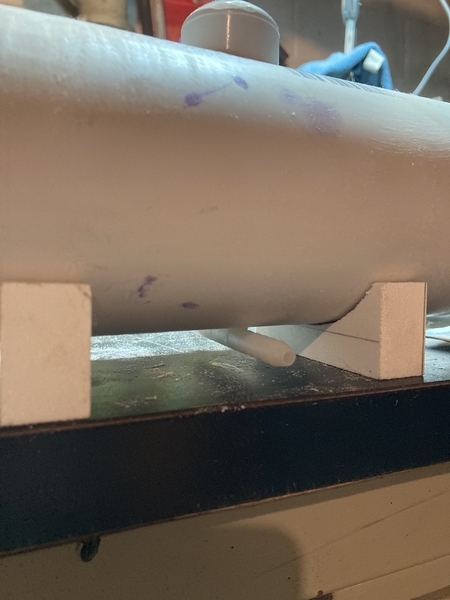

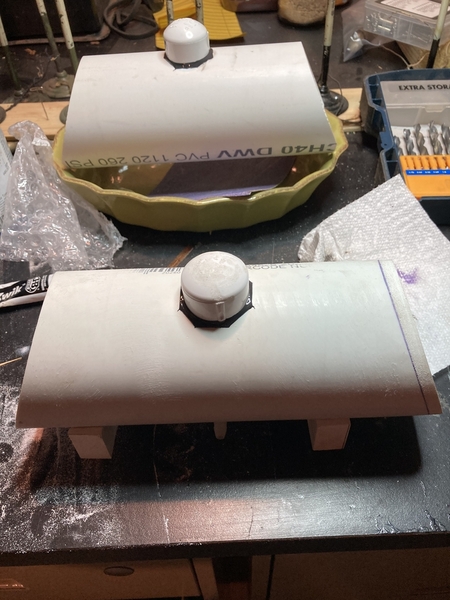

1 coffee can homemade water tower

1 3' glass top homemade station

1 437 switch tower

1 124 city station

1 436 power station

2 155 freight stations

2 120 tunnels

2 280 girder bridges

1 300 hellgate bridge

4 92 floodlight towers

2 438 signal towers

10 101 single span bridges

1 marx freight shed

1 marx switch tower

2 494 towers , one being a sand tower and the other a forest lookout tower.

1 cookie tin diner

1 3' tin roof station

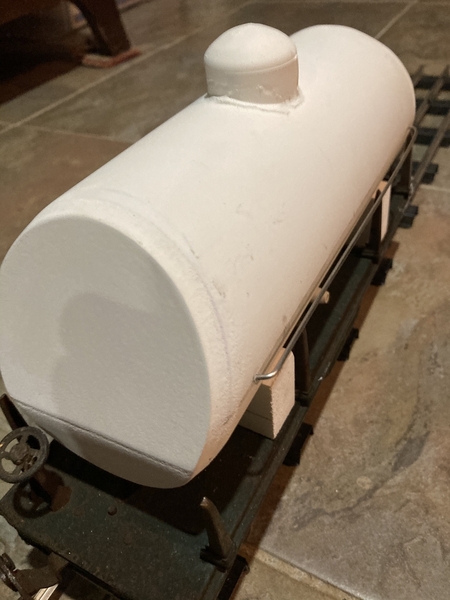

1 lighted water tower .