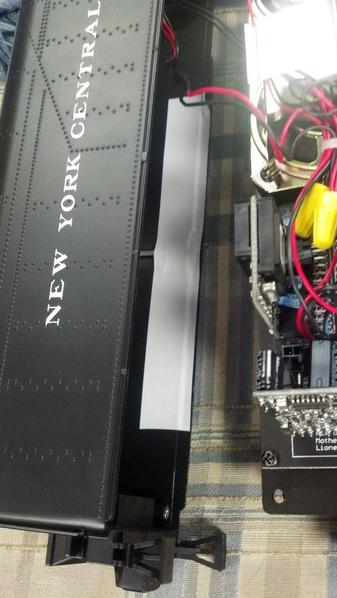

As I'm wrapping up all my little repair projects there's one phenomenon left I was curious if others have encountered. On my Lionel 28072 J3a Hudson, the tender emits a very high pitched rattle at any volume above the lowest preset. After disassembling it and checking for any loose items that may have been rattling against the speakers, it appears the rattle is actually the entire tender shell vibrating against the edges of the frame. If I squeeze the shell the rattle stops but when I let it go the rattle comes back.

I'm content to just leave the volume low but if there's an easy fix for this then I'd like to know. This is also the only engine I've ever had that does this. Thanks in advance.