Rather than hijack John's post and to allow for easier location of this thread in the future I moved it out of John's intro thread.

No parts were broken during this process if you're very careful at each step.

- Remove Truck screw and truck

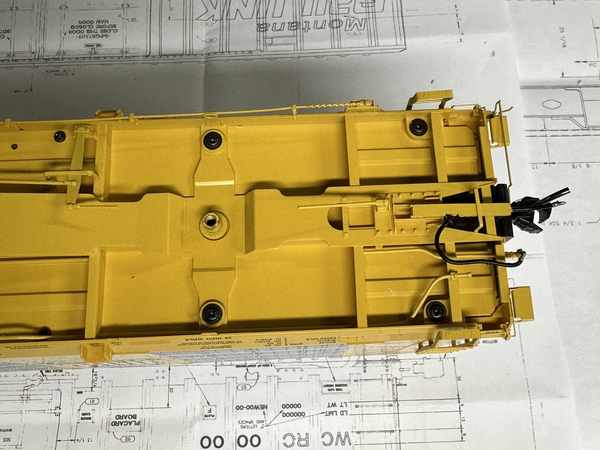

- Remove the 4 panhead w/built-in washer small screws you see below. thanks John for the photo! This portion of the underframe is removable, but also held into place by some of the brake rigging, so don't just pull it off or things will break!!!

Will look like this when finished

- Optional - The airline is attached as one piece and connects to the angle valve on the end of the car, it can be removed for easier access to the atlas and subsequent Kadee draft gear box, by slightly twisting the support bar which hold a larger pieces of plastic and the actual air line under the coupler. This larger piece of plastic also is glued in place but can be removed and lifted out if careful.

- The support bar is in the shape of a U with small lips on each side at the top which slide under gear box outer frames, removed in the photo above. Removing this support bar provided more access to the coupler boxes.

- Now it's time to carefully pry up near the screwholes the portion of the underframe exposing the gearbox. Be extremely careful NOT to pry to far or you will break something. Should look similar to the photo below. I've noted that you can gently rest the section on top of the stirrup steps without causing too much stress on the parts, but be careful and take it slow.

- You can now remove the atlas gearbox using the method of your choice, I use a small/thin flatblade screw at the rear of the atlas gearbox to pry back the slot on the gear box so that the tab in the lid is free . You can also insert a flatblade screwdriver into one of the slots in the rear of the box and while lifting up and twisting slightly the lid and/or tab will come free exposing the coupler, spring and screws to remove the atlas gearbox.

- Remove the coupler, spring and 2 phillips screws and the rest of the atlas gear box will come out

- A standard Kadee box with the ears trimmed off fit in the opening. Prep the hole close to the end of the car by using a 2-56 tap. Be sure to have the tap perpendicular to the opening as much as possible.

- I choose to clip the trip pins from my Kadee couplers and make sense especially with this cars airhose right under the coupler. I don't use magnets for uncoupling but if you do pay attention to the trip pin as it will likely be fouled by the airhose

- From here reassemble paying close attention to brake rigging and airline connections not to pinch anything to much as it will bend and ultimately break. Should look like the photo below

- Decide if all this work is really worth it!!! or just clip the atlas trip pin and call it a day. I may paint the kadee gearbox much like the atlas gearbox sticks out like a sore thumb.