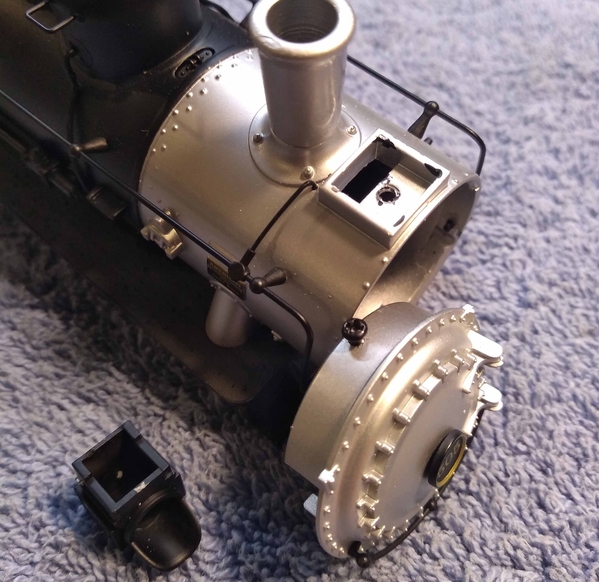

I bit the bullet and ended up buying one of the Atlas O 0-6-0 steam switchers... For my preferred railroad I had been watching for the two options available that have been made previously, either Atlas or MTH, and it turned out that after a long time watching an Atlas engine came up first and for a pretty decent price too. It appears to be nearly new if not actually new since the wheels and rollers looked pristine as did the rest of the model. Of course I went into this knowing these had some issues such as the drawbar and tether setup which was confirmed when I got it on the track. I've been considering trying to make some changes and improvements to the engine as a winter project and have a few questions for anyone out there who has had one of these apart...

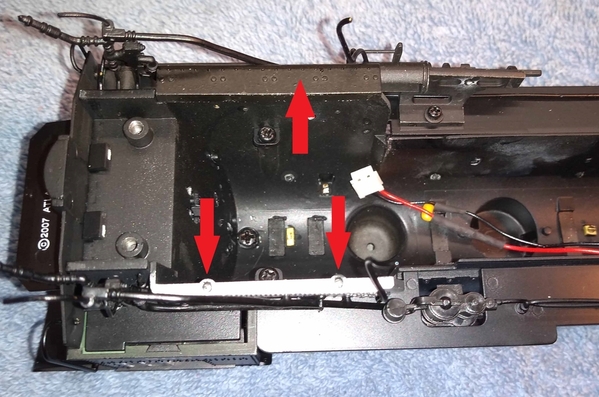

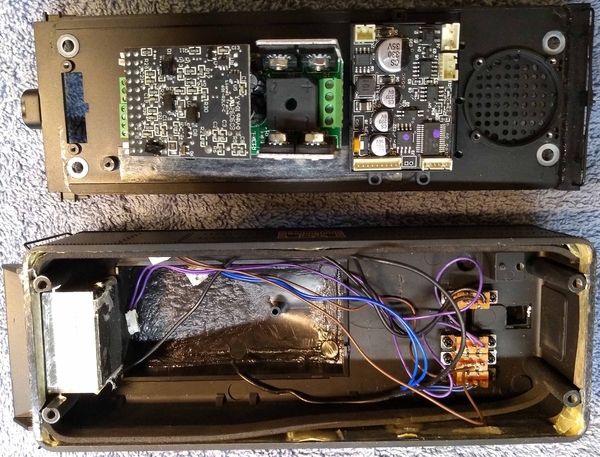

First, what are the "watch outs" or hints for getting the tender and locomotive apart, as in removing the shells? I've poked around on the tender a bit and it appears there are four screws from the bottom, one in each corner. The bottom didn't seem to budge though and I was hesitant to get too tough with it right away. Looking closely at the tender there almost appears to be a trace of adhesive on the bottom front and rear of the tank - did they do anything strange like both glue and screw the tender shell to the tender frame?

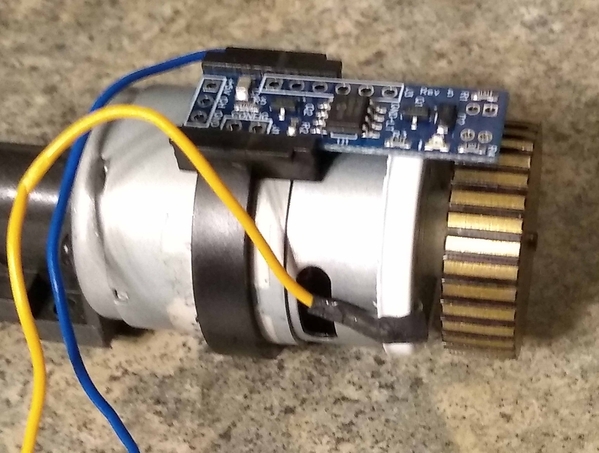

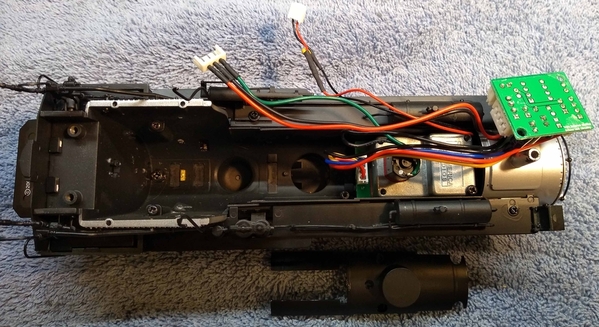

For the engine itself I've only seen a couple casual references made to it being difficult to disassemble but without much in the way of details beyond that... What should I look for, and likewise watch out for getting the boiler and cab off to expose the internals?

One more question for now, the manual makes no mention about the lights on the engine... I'm not sure if my eyes are deceiving me, but they almost appear to be LED's? Either way, can anyone confirm the voltage of the headlight, tender, and cab lights?