The Atlas SDP-35 is a very nicely detailed model. Weighing in at 2.2 kilograms, it's a very impressive beast.

Here it is on the left.

I've added a few bibs and bobs to the Weaver GP-38, so that it keeps up a little bit in detail.

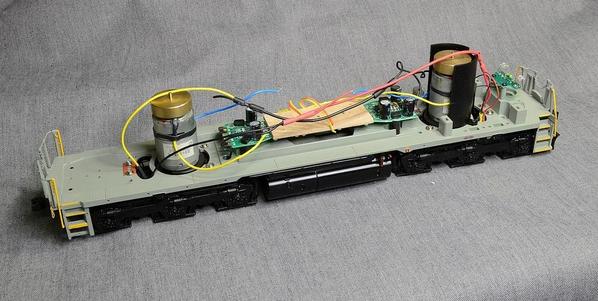

I've stripped the loco down and ground off all of the redundant bits on the board. Then I've fixed a piece of 3mm MDF on top to screw the Loksound mounting board on to.

I've lost a bit of clarity in the upload, but if you screw your eyes up you can see on the right hand end is a little board with the rear marker lights mounted on it. The grain of wheat lamps have made way for LEDs.

I separated the pickup wires as best I could, because Atlas have chosen the time honoured tradition of making the body of the truck one of the conductors. Perversely, it's the right rail on the front truck and the left rail on the rear truck. Go figure!

Also, Atlas have completely ignored the NMRA wiring colour code. ![]()

Not to worry. I've set the loco up so that there is no short circuit between the two.

Imagine my surprise when I mounted the Loksound daughter board and then plugged in the Loksound Select L decoder!

SHORT CIRCUIT. ![]()

And to add to the mystery, the short only happened when I plugged the decoder into the board. Unplugged = open circuit. Plugged = short. What can be happening, Holmes?

I eventually assumed that the decoder must be defective. Bryan at sbs4dcc came to the same conclusion. I ordered another decoder and a spare board from him. Then I removed the daughter board from the loco and made a decoder tester by attaching it to a piece of MDF. I have many spare speakers, LEDs et al and a spare motor which I took out of the Weaver.

Time for another surprise! The board/decoder combo worked perfectly on the tester. ![]()

Back to the loco, armed with my continuity tester. What I've discovered is that the bodies of the electric motors are connected to the frames of the trucks - and also connected to the (+) brushes of the motors. As the decoder is plugged in, the circuit between the wheels and the motors is complete.

Well, butter me on both sides! (Or words to that effect).

I must now disassemble the motors to see how to separate the brushes from the motor bodies.

"I shall return, in ze foolners of tarme, mes amis." Inspector Clouseau.