Just got an Atlas TT and made a few observations. Most people complain about the belt falling off. Being from an engineering background, I figured that would be easily solvable issue and it is. Still can not figure out why Atlas never addressed this years ago.

Even Atlas cautions not to run it "TOO" fast with out giving any parameters.

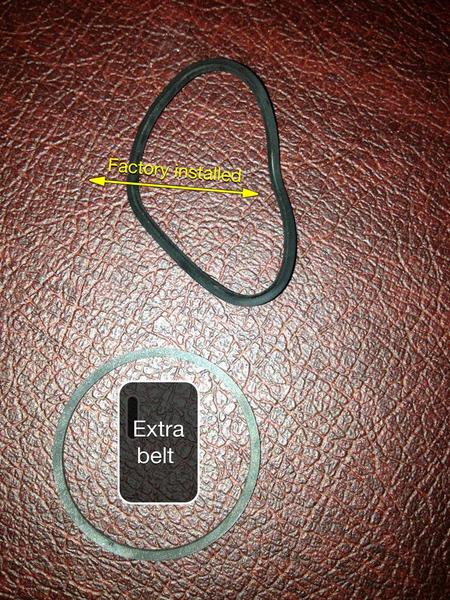

first problem is that the unit should be shipped without the belt installed. After long trip from China and sitting on shelf for a year, it looks like a triangle with an indent where it rests on the idler sheeve.

second issue is that the belt is too wide or sheeve to narrow (pick one).

the belt sits on sheeve at an angle which means that on a square profile belt, it is already half off and overstretched.

OnceI changed the belt and thinned it up with a piece of fine sandpaper, I test ran it for half an hour at full 18volts and had my son slam it into reverse a few times just for fun.

Never skipped a beat. I do not advocate this a a general opperating procedure.

also if you recommend lubing the gears than they should provide a small starter tube.

goes a long way toward customer relations.

I had another issue with the little guy in the shack was bouncing around and shack glued up tight. Atlas tech says this happens because the glue does not stick well to the rubber.

Customer service actually told me to send it back at my expense so he could cut the bottom off, re-glue the man and then ship back.

Said it did not affect the turntable from working.

Hello???

Me paying to ship, him spending the labor to dismantle and ship back has to cost more than popping a cheap plastic piece in the mail. And that still does not address the glue issue.

The Geneva index is a great idea. too bad whoever decided to use it could not figure out how to spec a simple rubber band.

Otherwise, for the price, it it a good option.