How about increasing the gear ratio so the bridge doesn't have the possibility to go as fast in one direction. For speed control, there may already be something that exists, how about using the ERR Cruise Commander to control the bridge? It already has the back-EMF speed control build in. Finally, I think Stan's idea of the counterweight is a good one to balance the loads going up and down.

Another method I have used on small animated projects is the screw shaft drive. Similar to some garage door openers. On this LGB mart craneI used the screw drive to raise and lower the boom and another to extend the boom.

Hi Dan, I like that idea, but I would have to find an old screw type opener and kit bash it. But that's ok, isn't that what its all about. I will start looking around for a free one. Till then I'm still open to ideas!

I think to even out the up and down speeds, the counterweight would be a good start. That's how the real bridges do it. ![]()

Thanks John, that's something I am going to work on today, after Christmas light install, Have to keep Momma happy first!

A screw drive is a very good idea. No need to kitbash. There are very good high-power units available on eBay or Amazon for reasonable prices.

Go to eBay and search for "linear actuator".

Here's a random example:

These are very nice devices. I should have though of them first.

Attachments

The counterweight is still a very good idea, even with this device. Equalizing the load going up and down will make things work much smoother.

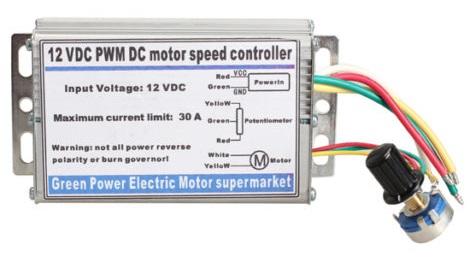

Moonman posted:...something like this Stan? motor speed controller

This is "just" a PWM controller. It does not perform constant-speed control. I guess it's semantics. Yes, it does control motor speed as you turn the knob, but at a given setting if the load torque increases the motor speed decreases. This also suffers from the kick-start problem; even if you found a setting that works for raising, I'm fairly certain you'd have to initially bump the knob clockwise for a second or two to get the mechanism started.

As for counter-balancing schemes or what I called option 2, this is a slightly different problem than a vertical lift-bridge. In that case the torque presented to a lift motor is relatively constant throughout the travel. So a "simple" pulley-weight works fine. In the angled-lift mechanism, the torque varies since gravity's effect on the moment-arm (or whatever the mechanical terminology) changes with the angle. You can "hear" this in the video when the bridge lifts; the motor speeds up near the top and you can hear the pitch/whine of the motor transmission increase. I may be mis-understanding the proposed pulley mechanism, but I think it would take a more complex counter-balance to present a constant-load torque irrespective of bridge angle.

Attachments

mike g. posted:So let me ask you this Carl, would the speed controller be wired in between the pedal and the motor? And back to my other question, would I have to adjust it for both directions?

That's how I would try it, Mike. it looked pretty nifty watching you use the pedal in the video. Set the knob and step on the pedal fully. The other option is to just turn the knob and leave out the pedal.

I did see some scooter and electric bicycle controllers and a twist throttle for about $50. They had too many plugs on the controller for other connections.

The electric go kart controllers are around $350 and complex, in that they step in multiple batteries. That didn't even include the throttle!

stan2004 posted:Moonman posted:...something like this Stan? motor speed controllerThis is "just" a PWM controller. It does not perform constant-speed control. I guess it's semantics. Yes, it does control motor speed as you turn the knob, but at a given setting if the load torque increases the motor speed decreases. This also suffers from the kick-start problem; even if you found a setting that works for raising, I'm fairly certain you'd have to initially bump the knob clockwise for a second or two to get the mechanism started.

As for counter-balancing schemes or what I called option 2, this is a slightly different problem than a vertical lift-bridge. In that case the torque presented to a lift motor is relatively constant throughout the travel. So a "simple" pulley-weight works fine. In the angled-lift mechanism, the torque varies since gravity's effect on the moment-arm (or whatever the mechanical terminology) changes with the angle. You can "hear" this in the video when the bridge lifts; the motor speeds up near the top and you can hear the pitch/whine of the motor transmission increase. I may be mis-understanding the proposed pulley mechanism, but I think it would take a more complex counter-balance to present a constant-load torque irrespective of bridge angle.

Thanks, Stan. I should have known that would be too easy.

If the electronics options (lots of techno mumbo-jumbo) is not in your comfort zone I'd think there are some mechanisms out there...most likely from the automotive world...that should be adaptable. For example, it seems a similar mechanism is the motorized-hinged tail-gate lift on a mini-van...or the motorized-hinged gull-wing doors on fancy cars. Varying torque is required to lift the gate or door (at constant speed) depending on angle. Likewise, varying torque (and less of it thanks to gravity) is required to lower the gate or door (at constant speed) depending on the angle. Obviously, in the automotive mechanism, the use of heavy counter-weights is not an option since that would add to vehicle weight. I can imagine these might be an application for linear-actuator motors as suggested earlier. In other words this is option 1 of finding a different motor gear/transmission that is stiffer in that speed variations are demoted in the presence of varying load torque.

OK so here is another question? If I went with a counterbalance and this do you guys think it would work?

mike g. posted:OK so here is another question? If I went with a counterbalance and this do you guys think it would work?

Almost certainly. I doubt you would need the counterweight (although it wouldn't hurt). I have used those things--they are incredibly powerful and smooth.

The reason I asked earlier about the Bascule bridge, is that it's the most common way of lifting an end pivoted bridge in the proto world. If you counter balance the bridge, it will take a miniscule amount of effort to raise it. Lowering it will also be easily controlled. Think of it like a see-saw or teeter-totter. Give it a few grams of positive down force and you will be able to raise and lower it with a tiny motor.

Even a model airplane servo.

The pulley idea won't work unless it located away from the pivot point of the bridge.

Extend the plane of the bridge past the pivot and add weight until the bridge is slightly down heavy.

You say the bridge is 40" long. Approximately how many pounds does it weigh?

Don't mean to insult anyone but basic high-school physics will ballpark the maximum (worst case) pounds the linear actuator must deliver to raise the bridge (starting from horizontal). Since travel of the linear actuator is less than 1 foot, you would presumably couple the linear-actuator a relatively small distance (also less than 1 foot) from the pivot point.

I'd think 200 lbs is more than adequate (no counter-weights needed) but why not measure-twice, cut-once. Doing the math might also suggest you only need, say, a 6" rather than 10" travel though it doesn't seem there is a gross cost penalty to buy the longer versions.

stan2004 posted:but why not measure-twice, cut-once.

You're no fun. ![]()

![]()

I'd consider at least the simple counterweight, that would remove a fair amount of the effort to raise and lower the bridge and give it some balance. If it was balanced at the half-way point, you'd have a lot less effort to raise and lower the bridge than without the weight. It's not only the effort to raise the bridge, but the strain imposed on mounting points for your lift mechanism. You may have plenty of power to raise and lower the bridge, but a mount might bust loose.

MaxSouthOz posted:The reason I asked earlier about the Bascule bridge, is that it's the most common way of lifting an end pivoted bridge in the proto world. If you counter balance the bridge, it will take a miniscule amount of effort to raise it. Lowering it will also be easily controlled. Think of it like a see-saw or teeter-totter. Give it a few grams of positive down force and you will be able to raise and lower it with a tiny motor.

Even a model airplane servo.

The pulley idea won't work unless it located away from the pivot point of the bridge.

Extend the plane of the bridge past the pivot and add weight until the bridge is slightly down heavy.

That's what I thought. I posted the same question to Banjoflyer. Scroll up a few posts to the diagram.

Hi all, thank you to everyone for there input. Here is what I came up with, I poured a counter balance to attach to the back part of the bridge just past the pivot point. its 7"W X 9"LX 31/2" thick. I am not sure what the weight will be but its more then that's there now. I also ordered the 10" Linear-Actuator just because they are out of 6" and 8".

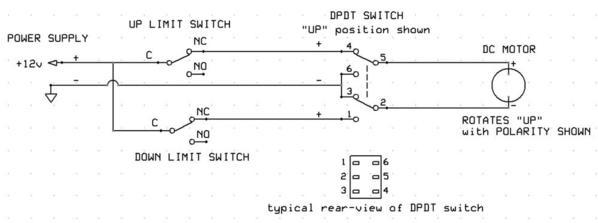

I am not sure what the bridge weights cause I didn't right it down like a fool. Stan if I just use a DPDT switch I would wire the limit switches just as before correct?

As far as the pivot point there are sealed bearings on each side.

mike g. posted:...Stan if I just use a DPDT switch I would wire the limit switches just as before correct?