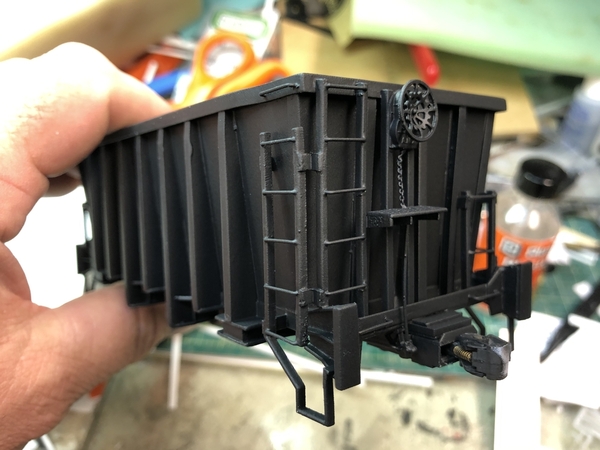

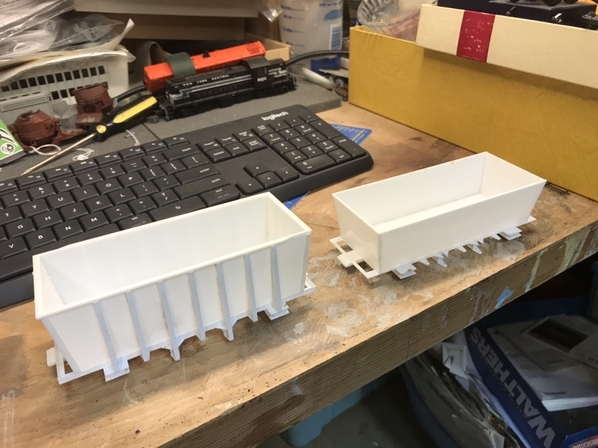

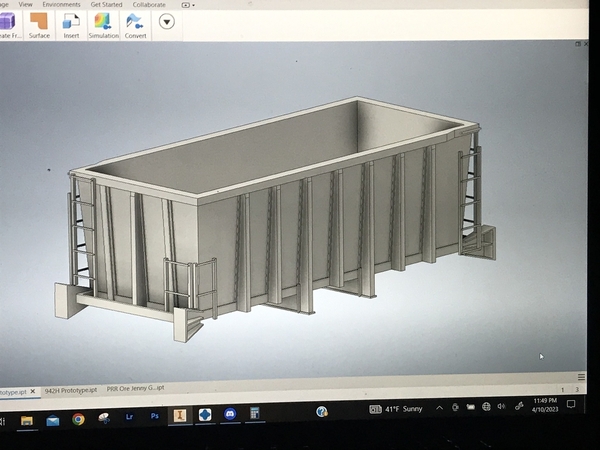

Version 5.0 construction is mostly complete. I may add cut levers and air hoses but debating these as they will be fragile and likely eventually break off. These cars are being built to run, not for a contest. I have a bit of cleanup - filing, sanding, etc., and then onto the paint shop. Painting will be a whole other challenge, as I have to perfect the stencil lettering. Plan B would be to have decals made up. Before all this, I want to test out the car’s running characteristics, hopefully this weekend. I have a slight concern that the bolster shape could be a problem and I might have to go back to a simpler design for better running. It might be as simple as milling the bolster flat and drilling for the truck screws on a drill press. I will be making improvements as needed as I build more of these.

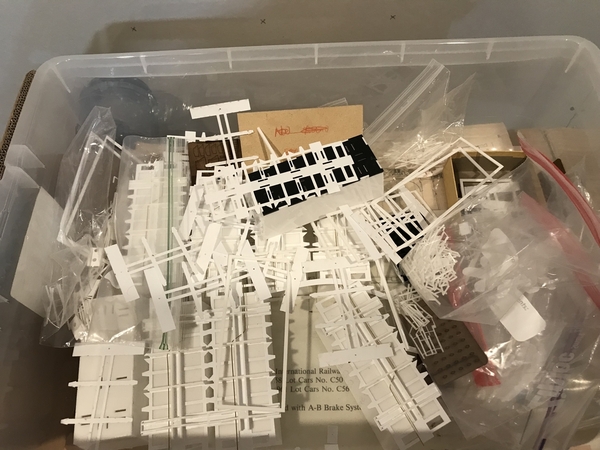

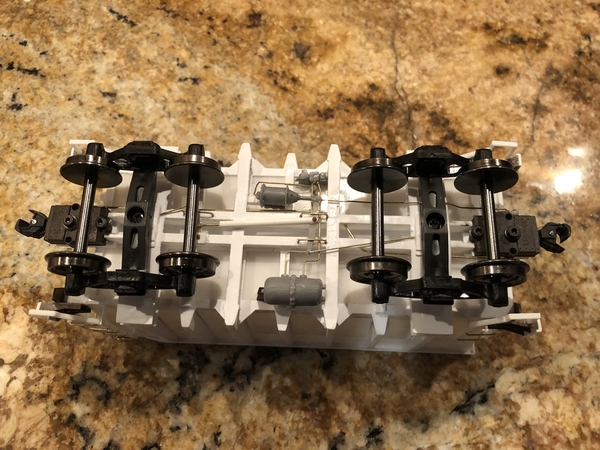

There were a few compromises made with the ladders as I had alluded to in an earlier post, but I’m happy with the result. They are cut from .060 acrylic, and include the steps, and two or three temporary “rungs”. The very thin temporary rungs are to maintain spacing while I bend and insert the individual .020 wire rungs, and are just cut out after all the wire is glued in. The laser “drilled” all the holes. The ladders should be fairly rugged for handling the cars, and surviving the occasional derailments at the club. The brake gear is Grandtline with wire and styrene where needed. The train air line is bent on a laser cut jig and the holes in the frame pieces have the holes pre-drilled from the laser - oval holes for where it passes through the main beam at an angle. The beams and bolster frames are slid onto the bent air line and then the whole mess is carefully fitted into slots on the car bottom.