I have three Marx streamliner coaches that I stripped and repainted. And..I think they look terrible. Has anyone ever used a chrome shop on tinplate?

Replies sorted oldest to newest

Somewhere, years ago, in some train show, I saw some chrome plated cars on a

table. That isn't a cheap process now, is it? Due to Big Brother, I heard people who

wanted the older style chrome dinette sets had to go to Canada after them.

Electroliner

I am working on doing some chrome work on an engine a little later this spring I got a chrome Plating kit from Micro Mark it is simple to use

later on I am going to get another kit and Chrome an entire engine with it. But for now I am only Chroming the side Skirts of a Williams 4-8-4 GS-4 The plating kits are not real expensive..

It's been over ten years ago that I had it done. I had my 616 black/chrome Flying Yankee redone. The metal cannot have any rust or corrosion. The more cleaning you do means less time for the shop. It is not cheap by any means. All four cars ran a little over, $400.00. Since California and the EPA got together, plating shops are few and far between. Shops here are sending their parts to, New Mexico and Texas now.

You might find that powder coating is more affordable. Many of the newer materials look like the real thing, well...almost.

Bobbie21921, I've thought about the same thing. I'd go with the nickel plating then buff and clear coat.

I have used the aluminum plumbers tape I picked up at Home Depot. More of a stainless look than chrome plating, but the price is right.

Steve

Attachments

I would get a Flying Yankee if they did the nose and tail in chrome instead of the horrible looking black! I know that's the way Lionel did it back in the day but being from Boston and a B&M fan it just doesn't look right to me. ![]()

I have old cars-

To chrome a radiator shell, I pay $500-$650 depending on the amount of rust which equals additional labor hours & additional "base" plates of copper or nickle.

I have powder coated " chrome". It is nothing more than dull aluminum. There is no real reflectivity.

If you can swing it, chrome is the way to go, you won't be disappointed.

One thing I have not tried- The home nickle plating kits.

The cost of chroming was a surprise. I appreciate as always the options other than chrome that were suggested. Another alternative that I have been mulling over are the very thin self adhesive sheets used by automobile modelers to "chrome" bumpers etc on their models. The application of this stuff seems daunting ( wrinkles, air bubbles etc) as well as finding the right width if it's available..then there's the matter of seams.I suppose if I could get the seam to match the roof line that could work. Then I would have to cut out the window openings, and fold this material back...a lot of delicate maneuvering.

There is a chroming system you can get that you spray on in different stages and you can do it to plastic metal and I think wood, no toxic chemicals

Heres a video for spray chrome

There is a chroming system you can get that you spray on in different stages and you can do it to plastic metal and I think wood, no toxic chemicals

Heres a video for spray chrome

Wow..not exactly inexpensive but cheaper than traditional chroming.

Chris,

I do not have the ability to post photos right now. my Yankee is chrome on both ends as well. Only the roofs are black. For the expense, I should have waited for one of the Stout auctions. It would have been cheaper to buy an original in C-7/8.

If anyone has used the system offered by Micro Mark, Sound Off! I'd like to use it.

Chris,

I do not have the ability to post photos right now. my Yankee is chrome on both ends as well. Only the roofs are black. For the expense, I should have waited for one of the Stout auctions. It would have been cheaper to buy an original in C-7/8.

If anyone has used the system offered by Micro Mark, Sound Off! I'd like to use it.

Count me in..I saw that Micro-Mark system in their catalog.

I posted above that I have the Micro Mark Kit and will be using it shortly

I have the copper Kit and I have the Chrome kit.

I will post a how to and photos as soon as I can get to it which with luck should be within a week. I have a couple of other things on the Honey dew list that have to come first you know the saying if Momma ain't Happy ain't Nobody Happy

The cost of custom chrome plating has skyrocketed in the past 20 years or so because of environmental concerns. Plating shops use some very nasty chemicals that are difficult and expensive to neutralize and/or dispose of safely. I don't know if EPA requirements for disposal are excessively expensive or not, but they have put many, many small shops out of the plating business and raised the cost enormously for those that are left. I can remember building custom motorcycles when I was in college and the cost of chroming an exhaust pipe or a fender was next to nothing. Those days are gone forever.

With regard to brush and spray plating setups, keep in mind that they are intended for small parts, not large surfaces. For chrome to be uniform and durable, it needs to be electroplated in a bath. Also, good quality chrome plating is a three-step process. Chrome doesn't stick well to steel and it is not completely opaque, but it is very, very shiny. A traditional plating process on steel consists of a base layer of copper, nickel over that, and finally the chrome. If you are plating brass, the copper layer can be omitted. Aluminum can be plated, but it is difficult and expensive to do. The plating will flake off if the job is less than perfect.

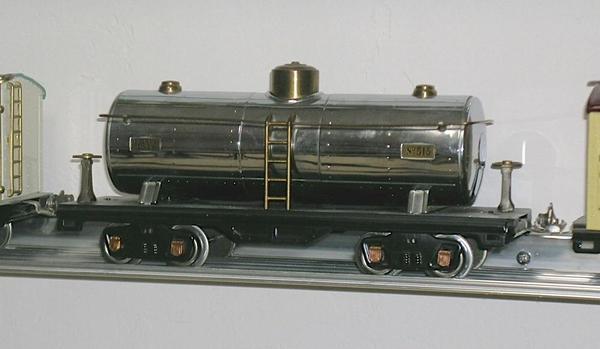

Here's a 515 tank car I picked up on eBay several years ago. Somebody did a very nice chrome job on it. Looks like it was done quite a while back, but still in excellent shape.

Attachments

Andy

It is self adhesive.

Steve

Yes, but how was it to apply to the carbody? Like around windows and such?

Yes, but how was it to apply to the carbody? Like around windows and such?

I had the same question in mind. I went to Lowes yesterday and found no tape in plumbing but did find it as heat resistant tape or silver ducting tape. It had 3M printing all over the tape..unusable. Steve..Where did you find this tape?

hi guys

try this site for chrome,have used in the past ,works well.hope this helps

http://www.bare-metal.com/bare-metal-foil.html

rich

Rich

That was the material I had in the back of my mind in an earlier post..my only concern would be burnishing carefully. I will have to measure the cars in question in relation to the length and width of this material to see if I can avoid seams.

Thanks much for the solid lead.

Bruce

Rich

That was the material I had in the back of my mind in an earlier post..my only concern would be burnishing carefully. I will have to measure the cars in question in relation to the length and width of this material to see if I can avoid seams.

Thanks much for the solid lead.

Bruce

Yes, but how was it to apply to the carbody? Like around windows and such?

I had the same question in mind. I went to Lowes yesterday and found no tape in plumbing but did find it as heat resistant tape or silver ducting tape. It had 3M printing all over the tape..unusable. Steve..Where did you find this tape?

Cool! Thanks Steve.

well today i worked with the Micro Mark Chrome kit and the Test pieces came out almost a Dull Aluminum Color which did buff up some

we are in a learning curve got to figure out what I did wrong

I have an idea that by copper plating them first dulls the final finish

but not sure though. Working on a solution will post pics if anyone is interested

well today i worked with the Micro Mark Chrome kit and the Test pieces came out almost a Dull Aluminum Color which did buff up some

we are in a learning curve got to figure out what I did wrong

I have an idea that by copper plating them first dulls the final finish

but not sure though. Working on a solution will post pics if anyone is interested

well today i worked with the Micro Mark Chrome kit and the Test pieces came out almost a Dull Aluminum Color which did buff up some

we are in a learning curve got to figure out what I did wrong

I have an idea that by copper plating them first dulls the final finish

but not sure though. Working on a solution will post pics if anyone is interested

read that the Copy Chrome solution is Nickel

Another option?

I recently had an old conductors lantern replated. It was finished in bright nickel, which has a chrome-like appearance. The company charged $175. to strip the lantern, replate it and ship it back to me. Here is the company I used.

read that the Copy Chrome solution is Nickel

Silly me, I thought that the chrome kit would be chrome. I should know better. I wonder what the difference is between the chrome kit and the nickel kit. Here's another suggestion. Try more polishing on the underlying surface before applying the plating. The guys in the business tell me the polishing is the key to a good finish. Also, be sure that any trace of polishing compound is cleaned off the surface before plating.

read that the Copy Chrome solution is Nickel

Silly me, I thought that the chrome kit would be chrome. I should know better. I wonder what the difference is between the chrome kit and the nickel kit. Here's another suggestion. Try more polishing on the underlying surface before applying the plating. The guys in the business tell me the polishing is the key to a good finish. Also, be sure that any trace of polishing compound is cleaned off the surface before plating.

So Did I

Chrome plating is chrome plating. It's not a paint and it's not a nickel plating, which looks pretty good, actually, and should hold up fairly well, although maybe a bit "yellow" in color. But painting or paint like stuff, or chrome powder paint is not the same, and it will never be the same.

Caswell makes some plating systems that use submersion or even pad plating with solutions, which may be good for side rods, trim, etc, however, large areas just generally do not turn out right.

On the other hand, if you take your flying yankee out to a hot rod chrome shop, it's not going to look right either. It's going to look too nice.

For what its worth, just buy the quality that you want in a chrome piece, and keep it dry. You'll end up dollars ahead, unless you want a chrome Mayflower set.

After reading all the great replies to my question, I took Steve's advice and went over to Home Depot where I found the foil tape in the HVAC section. Tomorrow I will experiment with it..and from the looks of it the stuff seems very workable.