Thanks, guys. I have no test cradle on hand. I overturned the loco and tender and used test leads. Seems to run fine without jackrabbiting into motion and without slamming to a stop. This is "wheels up" with no weight on the drivers at all of course.

BUT . . . while running slowly, if I ring the bell, or blow the whistle, without adjusting the throttle, it takes off and tries to go supersonic?

While pretty adventurous, I am reluctant to remove the brass shell from the chassis to get at the motor without some kind of diagram. Not clear to me how to take the shell off. The drive rods look complicated. I would hope it is not necessary to disassemble them first?

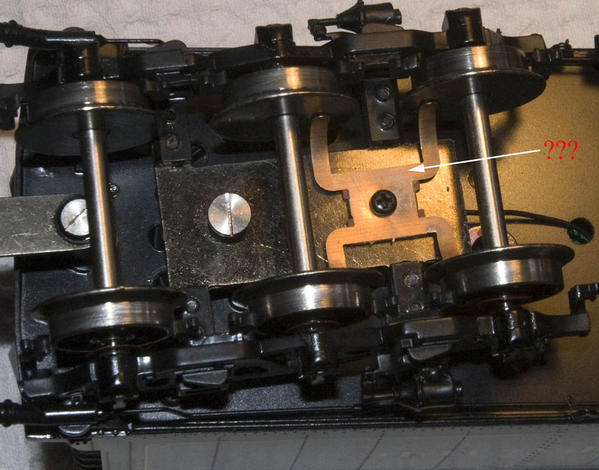

I removed the cover to the gear box to check on grease, thinking, a simple lube might help. There is no way for me to know how long this loco has sat in its box since being manufactured. (It's a Weaver CP2816 Hudson).

I was looking to see if there was anything obviously wrong with the gears. I saw nothing. Added a little white lithium grease. It occurred to me that the gears might be rubbing the gear box cover? So, I tried running it without the cover in place. That did not work at all! It moved a few feet and stopped, with the gears still turning, obviously out of mesh. I replaced the gear box cover and it ran as before, i.e., lurching into motion and slamming to a stop. Somehow, having that gearbox cover in place is necessary for the gears to mesh?

The loco runs fine at speed. There are no sounds indicative of their being anything hard

fouling up the gears, like a broken tooth.

But something seems wrong with its motor speed apprently being hypersensitive to small changes in voltage.

Seems I have three choices:

1/ Accept it as it is. Runs fine a reasonable speed.

2/ Try to get Weaver to service it.