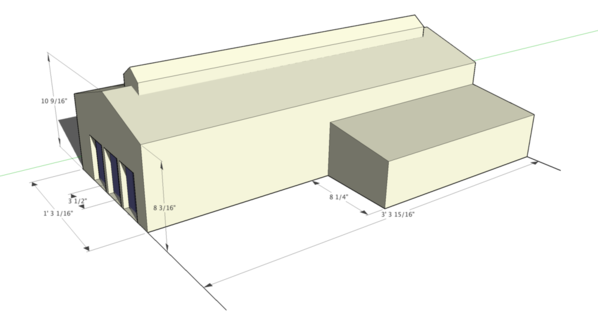

The supporting structures are really optional. It's really a chemical plant. Chemicals that you can drink. The kitchen is even exceeding my expectations.

Today I finished roof #2, got the lighting installed and then attacked the door and windows.

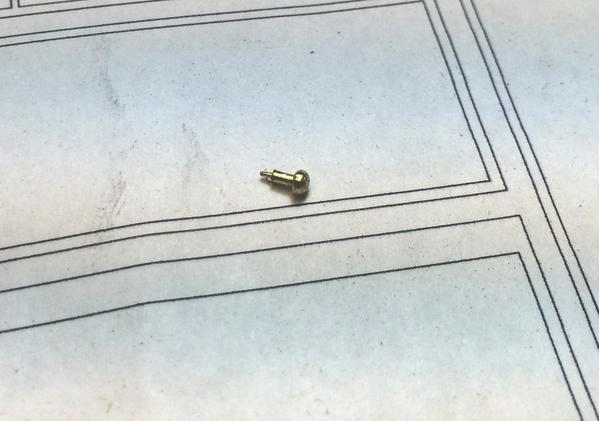

The first thing I did was turn a door knob. It ain't a door without a knob. I started with some 1/8" brass rod and turned the end down to a little over 1/16". I then used a tool which I had already ground a nice radius to form the front of the knob. I used a very narrow parting tool (also custom ground) to shape the stem down to something much smaller. The size isn't critical as long as i had a jeweler's drill in the neighborhood.

The stem turned about to be a #37 drill. I drilled the hole, inserted the knob and then used thin CA from the back to hold it in place. I also glue the window frame from the back using Aleen's glue, and then installed the "glass" (.010" clear styrene) using the liquid Pressure Sensitive Adhesive (PSA), and then installed the stain glass window. Before fastening in the stained glass I first installed a piece of clear styrene which gives the transparency film something to hold onto. I used a few drops of CA to hold the transparency to the styrene.

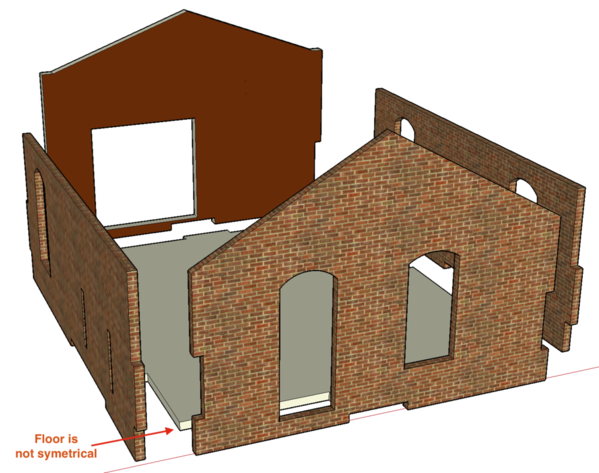

As i noted earlier, the production version of this kit takes care of some errors that I made in the initial design. This pilot is using parts in the first cutting. One of things I quickly realized is that the windows and doors need more than just a piece that fits perfectly in the opening. They need some support to hold them into the opening. For the Production version, I've added another layer that extends past the doors and window frames and holds them to the rear of the opening. For this pilot I had to add separate pieces to frame out the back of the door. It also blocks the excess light that would sneak out around the frames.

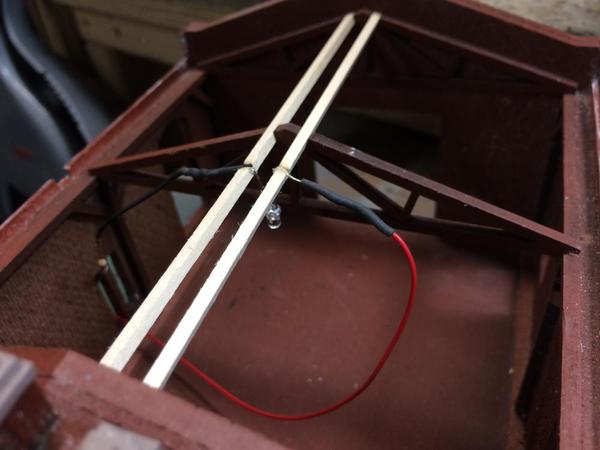

Before going further with the windows, I needed to get the lighting in place. Once the windows are in, it would be more fragile and handling it would be problematic. I'm using one single LED and I attached it to the purlins. I sawed a couple of notches in the purlins so the roof would close down tightly against them. I hooked up the LED, soldered the red and black leads to the + and - leads, and ran the wires out of the extra hole in the side (the one that was an error in the first drawing). I couldn't wait to light it up and hooked up the 12VDC source. Nothing. Reversed polarity and still nothing. What's wrong? Any ideas? Well... I'll tell you what's wrong. I did it again. In my haste to see if it lit, I forgot to install the 470 ohm current limiting resistor. The LED never had a chance. It blew out without even a whimper. I got another one, this time adding the resistor and the light worked perfectly.

Here was the first one mounted on the purlins.

That was the LED I blew out. Here's the installation complete.

The LED is secured to the purlins with some CA.

I added some shrink tubing pieces to the leads coming out of the building to keep them ship-shape. They'll tie into the lighting leads in the main building giving only one connection.

With the light done and checked (it worked!), I started on the windows. Because of my inexperience, my first designs for the windows were incomplete. I missed two key features. First, I didn't allow for any material to which to glue the bottom (inside) sash. Second, I didn't allow for any support to hold the windows in place and aligned.

So in this case I improvised by adding some of the same 1/32" ply stock (edges of the windows fret) to make side supports. I also added the supports just to the lower sash area to space it backwards one window-thickness thus allowing the lower sash to lie behind the upper, and, in the case of the front window, enable me to position the window open. In the production drawings this is all corrected making the parts look more like they should. Since this is an all masonry building the windows are inset into the walls. If it were a frame structure, the window designs would be reversed, more like how Bar Mills does their's.

I glazed the windows with the 0.010" clear styrene. For the windows I'm using three different kinds of adhesives: CA for to hold all the sash pieces together, Pressure Sensitive Adhesive to hold in the glazing, and Aleens PVA to hold the windows into the building. I use Chobani Yogurt cups turned upside down as glue receptacles. In this case, I put blobs of each type on one. Having them raised above the work surface makes it less likely that I will lay something in it, or get my hand on it. Notice I said, "unlikely", not "impossible". With me, nothing is impossible.

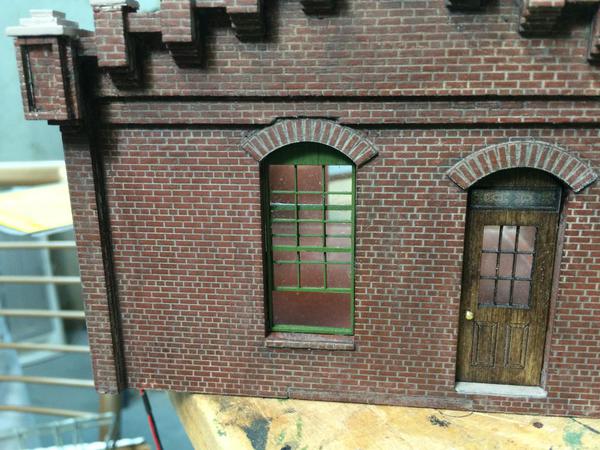

Here's the front window installed.

Here's the back view showing the extra material that's supporting the window.

A little bit of light can still leak out around the upper sash so I may just glue a piece of black construction paper butte up against the window to block that little gap that still exists. I did the same thing on the top of the door.

Here's another view showing the relief better. Those laser-cut bricks sure look good!

I could have made the curved lintels above the openings as part of the brick design. Instead I close to make it a separate piece so it's proud of the surface. I've seen buildings both ways. Any one have any opinions... not for this structure, but future ones?