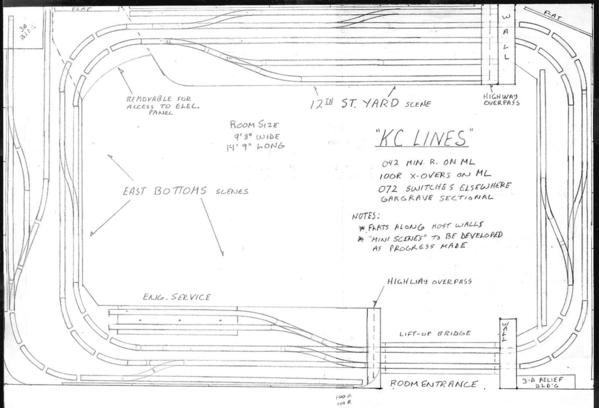

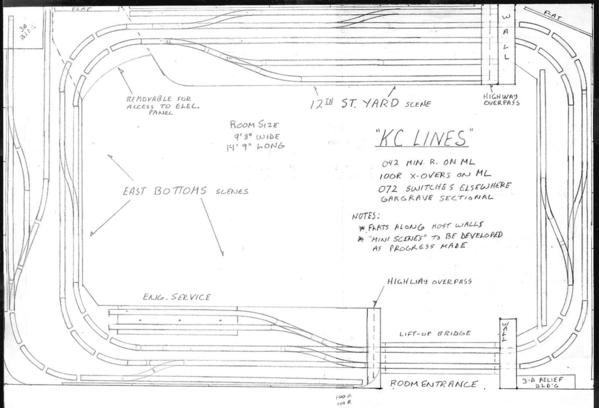

During my experimentation with 3 rail (early 2000s) to see if I could use the 3 rail medium to satisfy my desires in model railroading, which included with the ease of handling larger 3 rail trains, I designed an urban type switching layout to fit within a room of 9'6" width x 14' 6" length. (The 14' 6" length includes the closet.)

I had designed-in provision for double track loop running for those times I simply wanted to watch the trains run, or so I could have a train circling as I switched the industries.

The yard was to be treated like a "fiddle yard" in that I would manually swap cars on/off the layout in between "op sessions" for variety.

I actually got the entire double track main functional, all of the 12th St. Yard scene functional, some industry PhotoFlats created, constructed and in place, and was in the process of starting on the left wall industry tracks. Here's the original track plan:

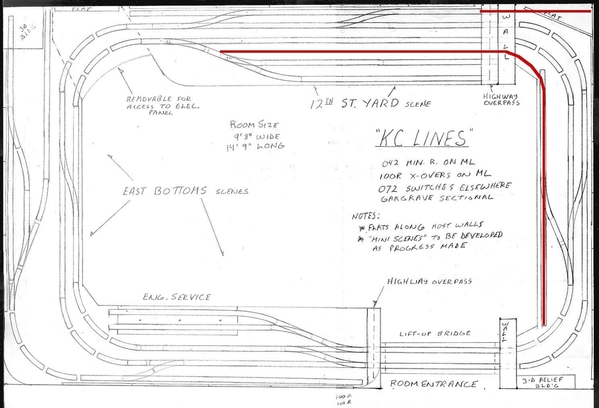

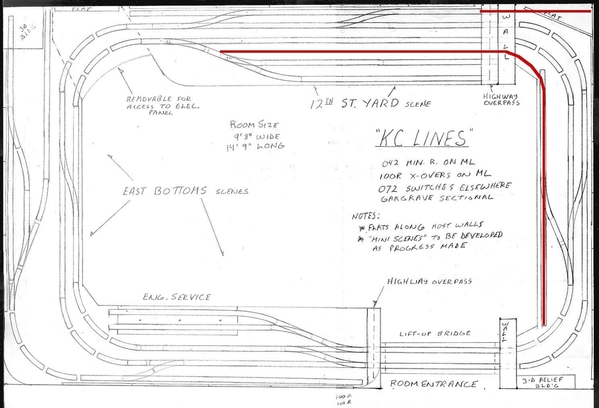

Once I had the 12th St Yard scene up and running, it didn't take long to see that I needed to revise the plan to do away with the switching area inside the closet, instead extending the industry track and inserting a long yard track for more car capacity, hence functionality. Doing would also eliminate concerns I began having about the user-friendliness of switching the closet scene. Here are those revisions shown in red:

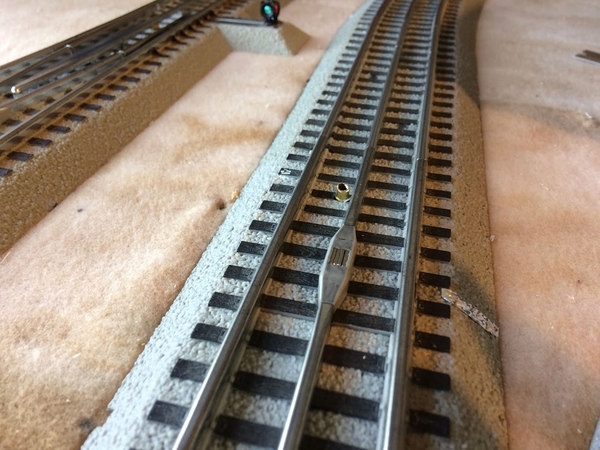

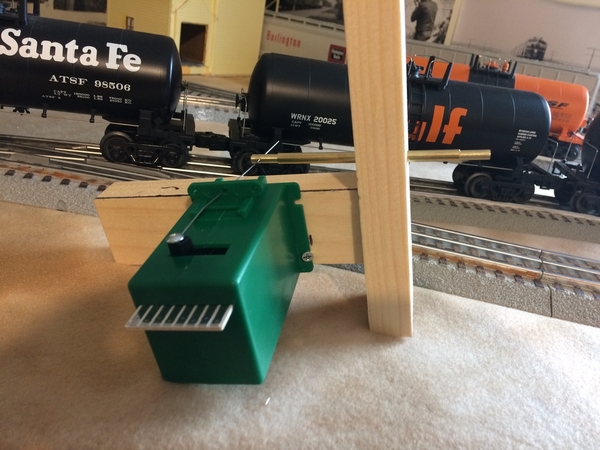

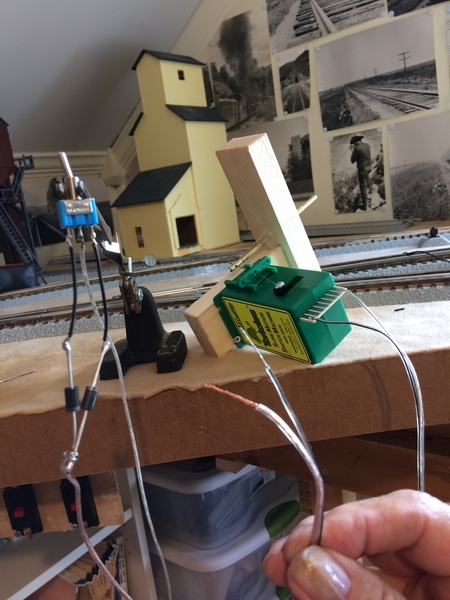

I liked the way the visuals were coming together in the 12th St Yard scene:

The reason for the decision against continuing in 3 rail has been mentioned before on these forums, so I won't rehash it here.

However, I did prove to myself that it was entirely possible to have a viable operational-based layout in a small space using 3 rail. In that respect, the experiment was successful.

Andre