I’m a novice, so I apologise if this is dumb idea or if it’s been discussed many times before. The flickering lights inside prewar and postwar Lionel passenger cars detracts from realism. Obviously having a pickup assembly on both trucks helps (particularly if the lights are wired together to run off either pickup), but bad connections can still happen.

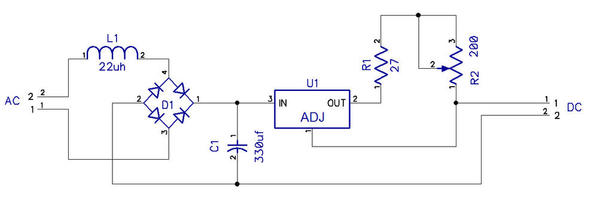

I thought the obvious solution might be to install a capacitor inside the car that could provide power to the lights when the pickup rollers momentary don’t make a connection. Has anyone tried this? If so, what value capacitor is recommended?