Dear Friends!

As you might already know I have finally made the decision to move on to Proto:48 standards. And now I am so excited about it that I get on everybody's nerves with that news. It's a small step for mankind, I know.

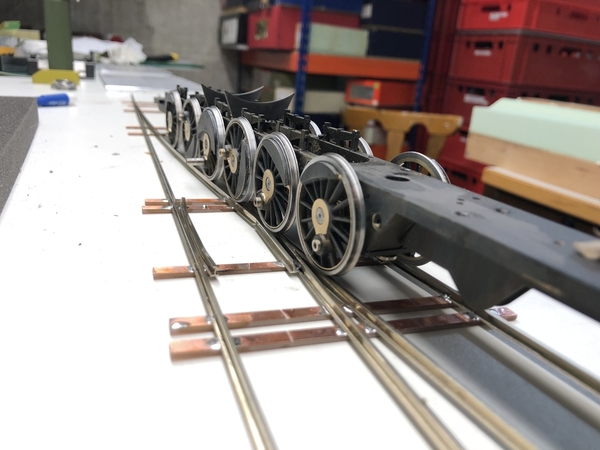

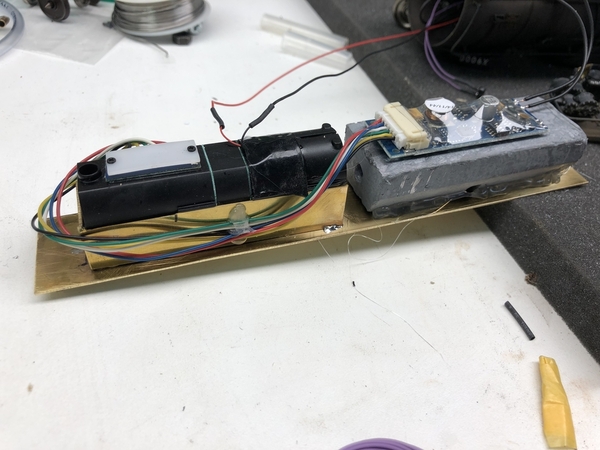

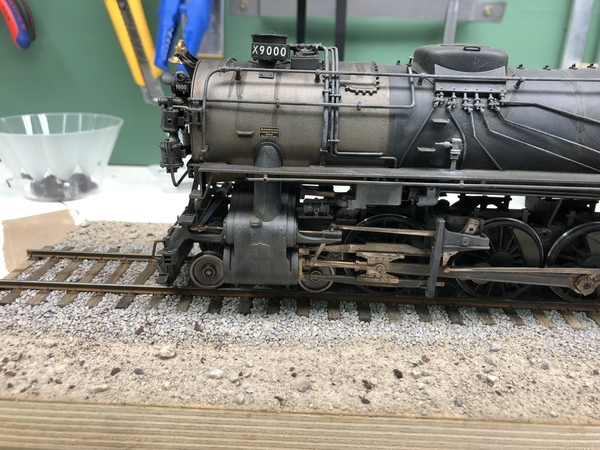

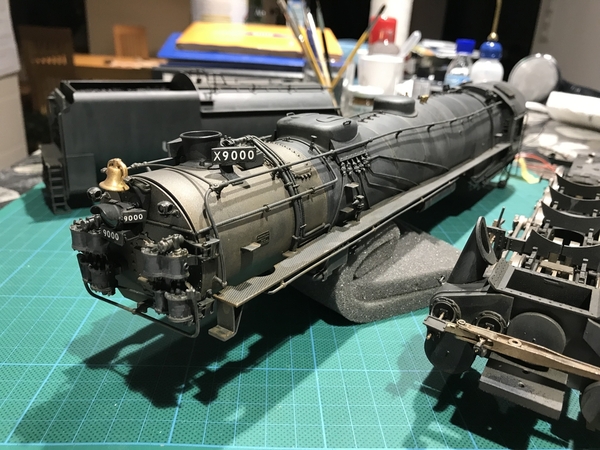

These are my first humble conversions of my Sunset UP 9000's drivers. I use the already filigrane architecture of the OW5 wheels to my advantage and remove material of the attached tire, so that is a simple conversion. Future projects might be more demanding. I have by now most of the tools together and first turning and milling experiences, I slowly learn how the different metals react and what they like and what not. Great adventure.

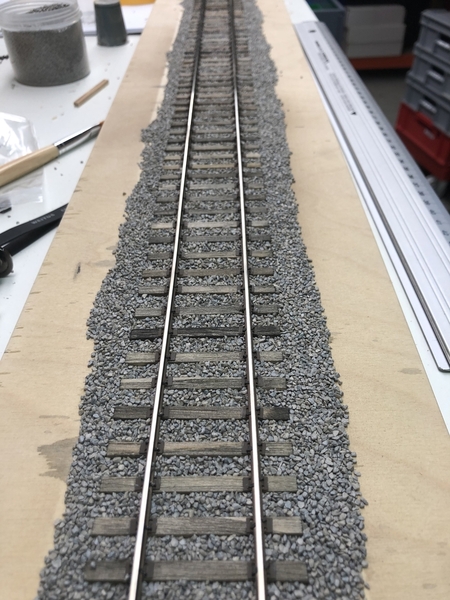

Just look how they 67" drivers sit on that code 125 rail. I'm so much into this now!

I would also like to say thank you to all of you that I had the pleasure to meet in Chicago. This is the worlds greatest hobby! Literally!

Sarah