I have a pretty hefty power module on it, rated at 3 amps, and probably easily will do 1.5-2.0 amps. I have it set at around 7 volts right now, and it runs pretty well, the Geneva gear takes about two seconds before the table starts moving to the next position.

@gunrunnerjohn posted:I have a pretty hefty power module on it, rated at 3 amps, and probably easily will do 1.5-2.0 amps. I have it set at around 7 volts right now, and it runs pretty well, the Geneva gear takes about two seconds before the table starts moving to the next position.

I haven’t tried it with a load yet but the 9.5 wart is rated at 2.2 amps I think. If it still struggles I’ll quit cutting corners and just put a dedicated adjustable power supply down there. I have plenty. Could probably use an old computer power supply now that I think about it. Heck, I’ve cut and soldered it 3 times now and that’s about my limit.

Wow, a 9.5V power supply should really make the table fly! Mine doesn't seem to struggle, and I'm still running with the old square belt. I have the replacement round belts, but I figure I'll wait until the square one breaks.

I did get my DZ-2500 switch machines powered up today, I have a couple of out the 24 that need work, one looks to be certainly bad, the other may be adjustment or the spring, we'll see. Once I get them all working mechanically, I'll hook up the serial data and program all of them for TMCC ID's.

Simply update tonight. Started dropping power feeds on the second half of the layout. Installed the base of the roundhouse, and added 2 more turntable tracks. Parked the newly acquired Dash-9 (which is DOA) on one of the new tracks. Looking for a PS2 3v board or a PS32 board (please help GRJ).

Attachments

@gunrunnerjohn posted:Wow, a 9.5V power supply should really make the table fly! Mine doesn't seem to struggle, and I'm still running with the old square belt. I have the replacement round belts, but I figure I'll wait until the square one breaks.

I did get my DZ-2500 switch machines powered up today, I have a couple of out the 24 that need work, one looks to be certainly bad, the other may be adjustment or the spring, we'll see. Once I get them all working mechanically, I'll hook up the serial data and program all of them for TMCC ID's.

12v made it fly. Was way too fast. 6v struggled to turn it and I hated it. 9.5 seems to do pretty well. 8v as you have would probably be better. Easy enough to swap around and find the perfect sweet spot once it’s farther along. This weekends plan is to have every track powered and be able to move locos anywhere I want under their own power.

What are you using between each track of the TT? It appears to match perfectly.

Did you consider using a 14183 TMCC-AMC to control your table?

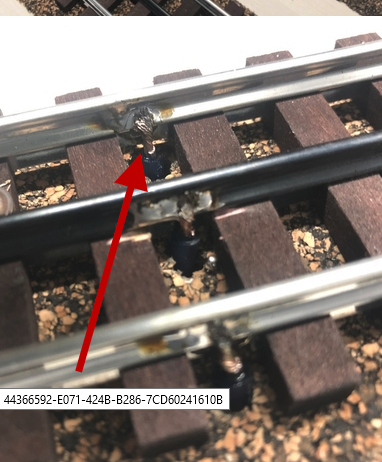

Important point on soldering on the track drops! The outside rail drops go to the OUTSIDE of the rail! If you have anything projecting from the inside of the rail, it'll hit the wheel flanges, bad things happen at that point.

Don't do this, I'd fix those.

Attachments

@Windy City posted:What are you using between each track of the TT? It appears to match perfectly.

I’m not sure what you’re asking. I use Midwest cork as roadbed and while atlas claims it’s a perfect match, there is a tiny incline where each track meets the table. Then the table rails sit a tiny bit higher than the track leading to it. None of it is an issue, but it does exist. The big boy goes on and off of it without problem. About 3 ties back from the table on each track I use 2 track screws to pull it down evenly.

@gunrunnerjohn posted:Important point on soldering on the track drops! The outside rail drops go to the OUTSIDE of the rail! If you have anything projecting from the inside of the rail, it'll hit the wheel flanges, bad things happen at that point.

Don't do this, I'd fix those.

Agree and it looks worse from the side. I make sure the solder and wire are inside of the rail web and on every single one of these I have done the flanges do not touch the wire or solder. They are all done on the inside as to not see them. If I run into issues I’ll move that one wire to the outside but so far it’s been good. Thanks though.

@Windy City posted:Did you consider using a 14183 TMCC-AMC to control your table?

No I did not. Currently I am exclusively MTH and quite ignorant to all the options out there. I have a power supply and rocker switch at the moment.

I don't think the AMC brings anything substantial to the party for the Atlas TT. A simple bang-bang control is all that is required by this TT design.

I am curious what these gray pie shaped items are between tracks of the turntable?

@Windy City posted:I am curious what these gray pie shaped items are between tracks of the turntable?

The base of the Atlas roundhouse I will be building. Put it down to get a visual of the size.

Any of you ever get lost on your own layout? I got most of the wiring done and started running trains. Within 3 minutes I had a traffic jam and had to completely stop to figure out how to get from point a to wherever. Can’t even fathom trying to figure out a setup like gunrunners. Of course, sticking to my “no picking anything up to move it” rule, I found myself backing around the entire layout once or twice to get on the end of the train I wanted to be.

Have an electrical mistake somewhere. Derailed and it tripped the breakers on both bricks. Loops are supposed to be isolated so I’ll have to trace that down and correct it. Also quickly figured out the polarity in the turntable manual is wrong. Pulling on the table the first time shut everything down in a small blaze of sparks.

LOTS of work and fine tuning to do. Mostly in the switches. Some are smooth and some are rough. Plenty of tweaking to do I’m sure. Shot a 2 train video that I’ll post later.

Having a blast.

I’ve had similar issues, and my layout is less complicated than yours. I haven’t even tried to follow John’s layout plan! 😄

That's Beautiful! I really like 4-4-0 engine! First time I've seen one of them in action.

Your layout is looking amazing and the speed at which you have this much completed is impressive!

@Sparty1225 posted:Your layout is looking amazing and the speed at which you have this much completed is impressive!

Thank you. I’m actually trying to pace myself so I don’t get too much done too quick. Pacing has also stopped many mistakes before they happened. The plan as of now is structure and proper running this winter and scenery next winter. We will see how well I stick to it though.

@Mark Boyce posted:I’ve had similar issues, and my layout is less complicated than yours. I haven’t even tried to follow John’s layout plan! 😄

My issue is just learning how the double-slip switches work, they're a really odd beast! Two of them together makes for interesting switching! The goal of the layout plan was to be able to reverse on the loops if desired, that got a bit more convoluted than I thought. I also wanted to be able to drive off the turntable and easily go either way on the service loop. Another goal was to be able to enter the other loops in either direction. The switches just seemed to multiply to get all that done. ![]()

I’m sure most of you already know this, but it’s amazing what you can learn if you just “listen” to your layout.

Ive spent the past few hours with a train just making loops and everywhere it sounds “off” I make adjustments while it’s on the other side. Much more pleasing than just trying to slide something back and forth. Some pliers and a grinder wheel on the dremel have made a world of difference already. Remember, all my switches are used.

Need some advice please. Layout is wired and I have switches to isolate power to inner and outer loops, as well as having the layout cut in half. Basically 5 switches. The fifth is for a programming track.

That being said, the turntable and its leads are powered at all times when the entire layout is “hot”. I have 2 schools of thought here and would appreciate input.

1- anything parked there is having its battery charged no matter what is going on which seems like a good thing.

2- unnecessary hours are being accumulated by the parked locos and the electronics are powered up possibly diminishing their life unnecessarily.

3- (I said 2 but oh well), when I derail or have a mishap on the inner loop, which is where the TT is wired to, when I restore power everything in the TT area starts up in conventional. Not really an issue other than the noise and of course in a perfect world I wouldn’t derail or have issues.

Anyways, open to thoughts on if I should have a switch to kill the TT and it’s leads when not in use.

Got some different distribution blocks from Amazon and like these even better than the first ones I got. Much easier to work with. I’ll end with a pic of one of the new blocks and a short video of parking the Big Boy for the night.

Attachments

David

Very late finding your thread here and will read and catch up. Impressive layout. I’ll have share some shots of mine that I completed back in the early 2000’s. Pre DCS Days

Are you going to add signals to your layout? I have Custom Signals on my layout. You might want to make some adjustments to isolate your outside rail now before you ballast the rail

What type of ballast are you going to use? I went with Brennan’s better Ballast process and brought the rail alive.

Forgive my question, I haven’t read through all of the posts

@CSX FAN posted:David

Very late finding your thread here and will read and catch up. Impressive layout. I’ll have share some shots of mine that I completed back in the early 2000’s. Pre DCS Days

Are you going to add signals to your layout? I have Custom Signals on my layout. You might want to make some adjustments to isolate your outside rail now before you ballast the rail

What type of ballast are you going to use? I went with Brennan’s better Ballast process and brought the rail alive.

Forgive my question, I haven’t read through all of the posts

As you’ll find as you catch up, I’m unsure of most things. But I’ll try to answer what I can.

Hadn’t given signaling much thought. I like the idea, but it just appears to be another thing I need to research more. As of now both outside rails are joined together at every power drop.

For ballast again I’m not sure. I’m known to get bored and want to make changes so still deciding how “permanent” I want the ballast to be. In the mean time, I have 5 pounds of Brennan’s ordered to see how I like it.

Great progress David. I like your approach of "listening" to your layout. The more problems you can fix now the more you will enjoy the layout later.

I liked both videos too. What is your wife so diligently working on? And what's the cat's name? We had a Siamese blue-point when I was growing up. Her name was Roka (like the cheese). She lived to be 18! She used to love to chase my trains around the layout in her younger days.

Also love the poster from The Shining "Here's Johnny!" . One of the best movie lines of all time. ![]()

A thought on ballast. You can just ballast the outside of the track. It gives the appearance of ballast without fouling the tack itself and would make changes easier to do.

Keep up the good work.

Bob

@David K. Simpson posted:That being said, the turntable and its leads are powered at all times when the entire layout is “hot”. I have 2 schools of thought here and would appreciate input.

1- anything parked there is having its battery charged no matter what is going on which seems like a good thing.

2- unnecessary hours are being accumulated by the parked locos and the electronics are powered up possibly diminishing their life unnecessarily.

3- (I said 2 but oh well), when I derail or have a mishap on the inner loop, which is where the TT is wired to, when I restore power everything in the TT area starts up in conventional. Not really an issue other than the noise and of course in a perfect world I wouldn’t derail or have issues.

Anyways, open to thoughts on if I should have a switch to kill the TT and it’s leads when not in use.

Personally, I don't believe you should have all the engines powered on all the TT whisker tracks for a variety of reasons.

- First off, the possibility of damage is always present from a transient elsewhere on the layout.

- Next, they're all consuming power for no reason and running up the operating hours

- Finally, there are times that if MTH locomotives start up in conventional and get a power interruption, they will take off at full speed, probably not desirable for all of them to attempt to converge on the TT bridge. TMCC locomotives wil also do that if they don't sense the TMCC track signal.

@David K. Simpson posted:Need some advice please. Layout is wired and I have switches to isolate power to inner and outer loops, as well as having the layout cut in half. Basically 5 switches. The fifth is for a programming track.

That being said, the turntable and its leads are powered at all times when the entire layout is “hot”. I have 2 schools of thought here and would appreciate input.

1- anything parked there is having its battery charged no matter what is going on which seems like a good thing.

2- unnecessary hours are being accumulated by the parked locos and the electronics are powered up possibly diminishing their life unnecessarily.

3- (I said 2 but oh well), when I derail or have a mishap on the inner loop, which is where the TT is wired to, when I restore power everything in the TT area starts up in conventional. Not really an issue other than the noise and of course in a perfect world I wouldn’t derail or have issues.Anyways, open to thoughts on if I should have a switch to kill the TT and it’s leads when not in use.

Got some different distribution blocks from Amazon and like these even better than the first ones I got. Much easier to work with. I’ll end with a pic of one of the new blocks and a short video of parking the Big Boy for the night.

WOW, Makes me want to grab a layzee susan and see if I can make a prototype for my Postwar. Love the BIG BOY and BIG SMOKE. Great video sequence and loving the cat, checking it out in the background. "Do you know Ms. Kitteh?" thanks for the share. very nice

@RSJB18 posted:Great progress David. I like your approach of "listening" to your layout. The more problems you can fix now the more you will enjoy the layout later.

I liked both videos too. What is your wife so diligently working on? And what's the cat's name? We had a Siamese blue-point when I was growing up. Her name was Roka (like the cheese). She lived to be 18! She used to love to chase my trains around the layout in her younger days.Also love the poster from The Shining "Here's Johnny!" . One of the best movie lines of all time.

A thought on ballast. You can just ballast the outside of the track. It gives the appearance of ballast without fouling the tack itself and would make changes easier to do.

Keep up the good work.

Bob

She’s working on a paint by numbers painting. I laughed at the idea at first until she bought one and I was blown away by how intricate it is. I can’t even see half of the little spaces that she is painting.

cats name is Samus. There’s another one running around somewhere but she’s the curious one.

@David K. Simpson posted:Need some advice please. Layout is wired and I have switches to isolate power to inner and outer loops, as well as having the layout cut in half. Basically 5 switches. The fifth is for a programming track.

That being said, the turntable and its leads are powered at all times when the entire layout is “hot”. I have 2 schools of thought here and would appreciate input.

1- anything parked there is having its battery charged no matter what is going on which seems like a good thing.

2- unnecessary hours are being accumulated by the parked locos and the electronics are powered up possibly diminishing their life unnecessarily.

3- (I said 2 but oh well), when I derail or have a mishap on the inner loop, which is where the TT is wired to, when I restore power everything in the TT area starts up in conventional. Not really an issue other than the noise and of course in a perfect world I wouldn’t derail or have issues.Anyways, open to thoughts on if I should have a switch to kill the TT and it’s leads when not in use.

Got some different distribution blocks from Amazon and like these even better than the first ones I got. Much easier to work with. I’ll end with a pic of one of the new blocks and a short video of parking the Big Boy for the night.

David,

Please send a link for the distribution blocks you found helpful.

URBEST 5Pcs Terminal Block... https://www.amazon.com/dp/B074...ppx_pop_mob_ap_share

Thank you David

@Windy City posted:Thank you David

They are great because you can cut the jumpers and make the blocks have as many shared connections as you want.

@gunrunnerjohn posted:Personally, I don't believe you should have all the engines powered on all the TT whisker tracks for a variety of reasons.

- First off, the possibility of damage is always present from a transient elsewhere on the layout.

- Next, they're all consuming power for no reason and running up the operating hours

- Finally, there are times that if MTH locomotives start up in conventional and get a power interruption, they will take off at full speed, probably not desirable for all of them to attempt to converge on the TT bridge. TMCC locomotives wil also do that if they don't sense the TMCC track signal.

Going to leave the turntable lead and the table itself on normal track inside loop power. Should I just have all the whiskers wired as one or put individual switches in for each whisker? The latter sounds like a pain.

I left my turntable lead and the actual bridge on the service loop power, I don't see a problem with that. However, I am individually powering the whisker tracks for what I think are a number of good reasons.

Powering up all the locomotives on the tracks risks a lot of the same issues I previously mentioned if you left the whisker tracks powered all the time. If you have a DCS locomotive that's not in the remote, and you try to add it with a dozen other locomotives all powered up, the chances of success are pretty small. The same issues with start-up in conventional mode and potentially taking off at full speed are obviously multiplied having a bunch of stuff powered up. Finally, all those locomotives having power are likely to degrade the DCS signal, exacerbating the very problems previously mentioned.

Bottom line, wiring a layout is a PITA, but it's got to be done. ![]()

So when you put power to an individual whisker, will you reset the TIU so that the watchdog signal goes back out or just accept that the loco on that whisker powers up in conventional and then take control by hitting start up?

We are going to use individual power for each whisker and control with the remote. Yes, it is a PIA but one remote will control all of the engine service area tracks, turnouts, etc.

We set up the passenger and freight yards and passenger station track power this way using DCS, an AIU, and relays, and they do fine. We used touch toggles for the turnouts and will probably switch to the remote.

Thanks.

@David K. Simpson posted:So when you put power to an individual whisker, will you reset the TIU so that the watchdog signal goes back out or just accept that the loco on that whisker powers up in conventional and then take control by hitting start up?

I don't have to reset the TIU, that's why I have the perpetual barking watchdog generators on the outputs of everything but the mainline. ![]() These continually send out watchdog signals ever second so that I don't have to be concerned about DCS engines waking up when I apply power without resetting the TIU channel.

These continually send out watchdog signals ever second so that I don't have to be concerned about DCS engines waking up when I apply power without resetting the TIU channel.

Perpetual Barking Watchdog Board Topic Link

Attachments

Fascinating.