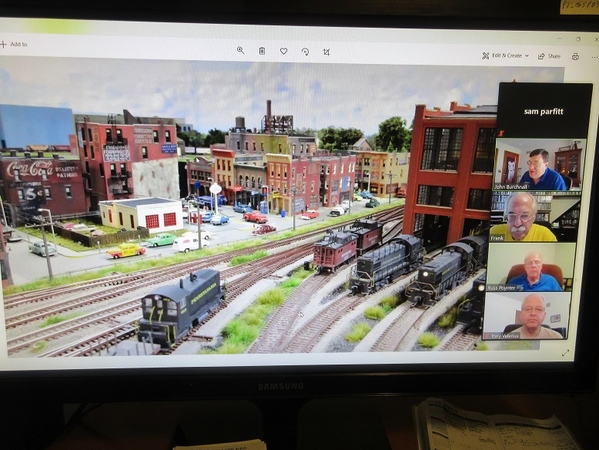

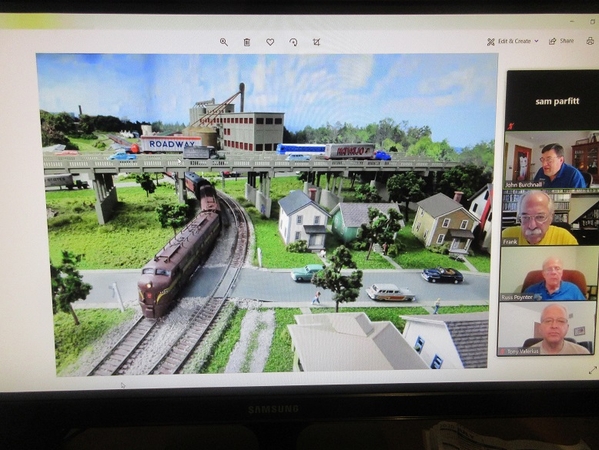

GNRW operating session, July 18.

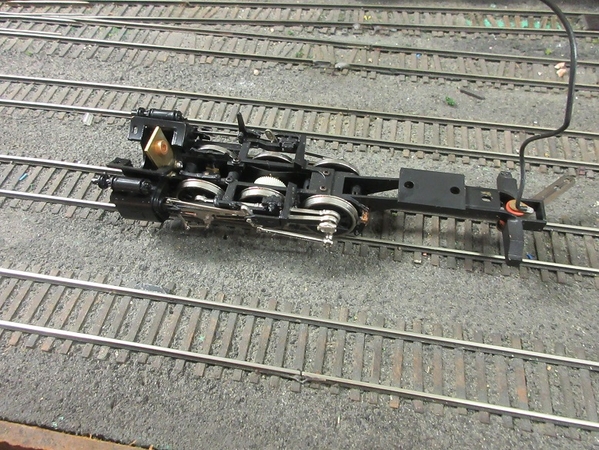

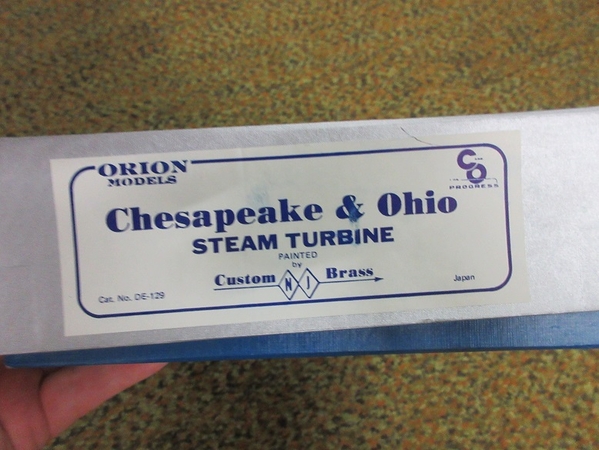

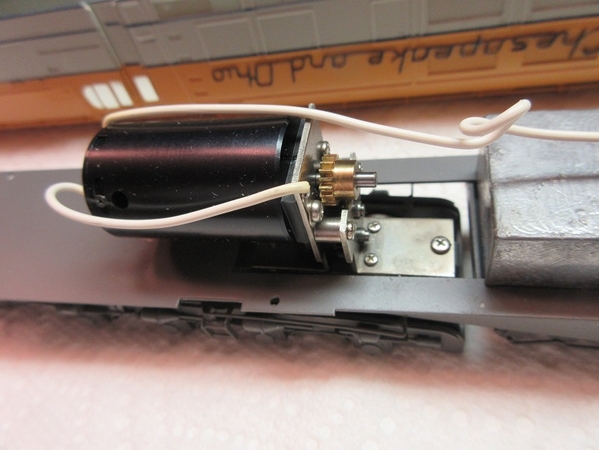

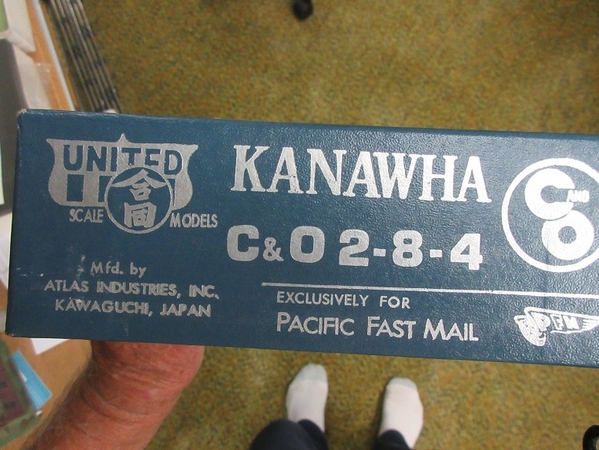

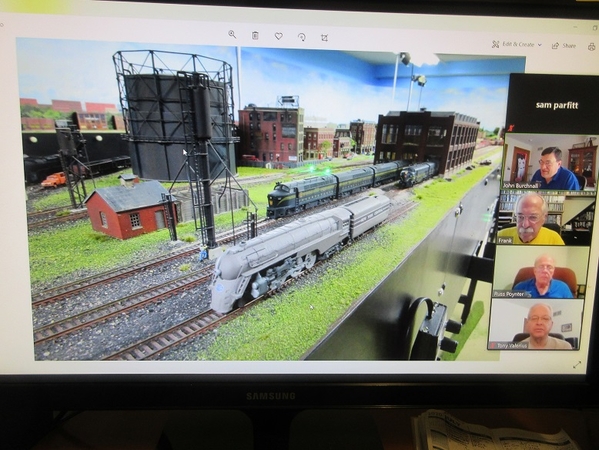

First one out was the new C&O M-1 steam turbine. Wasn't sure what it could pull so only put 30 freight cars on her 'maiden' trip: No problem handling the train. Pizza arrived so all activities, save eating, stopped!

C&O M-1 turbine video:

https://www.youtube.com/watch?v=zs8Am04c4lo

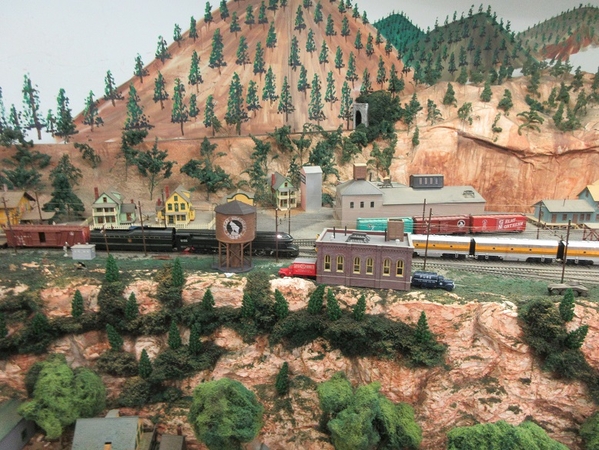

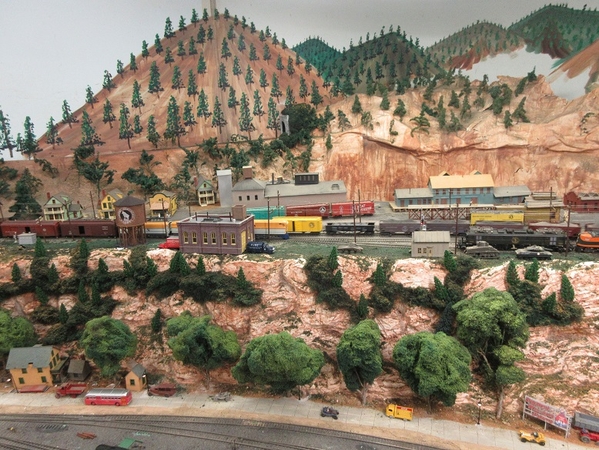

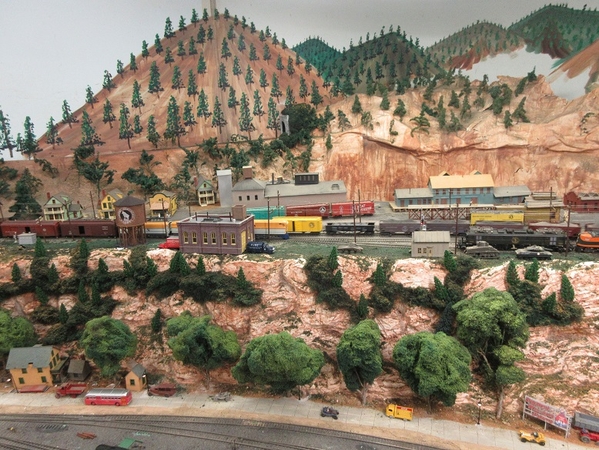

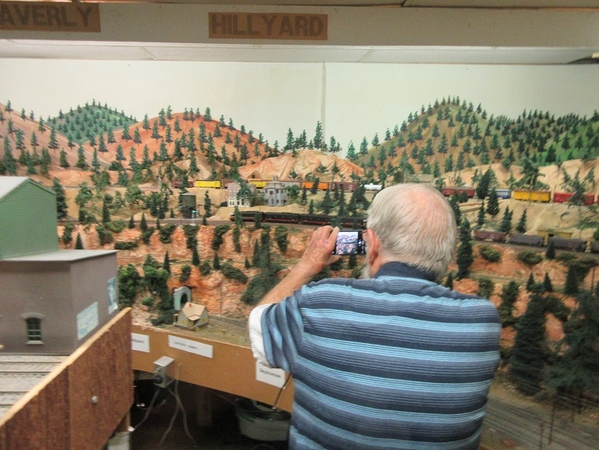

Taking on water at Hillyard.

Hillyard station.

Dave with a freight drag pulled by a GN R-2 2-8-8-2.

Bob's SP AC-9 2-8-8-4 at Wilmar.

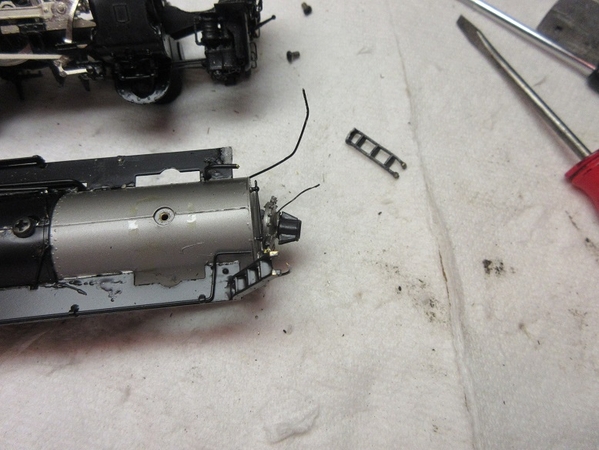

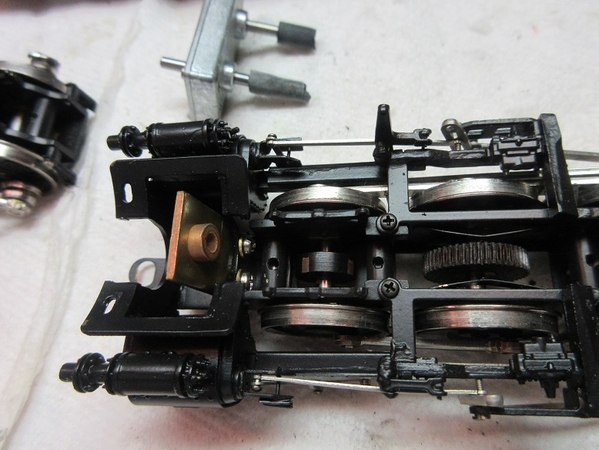

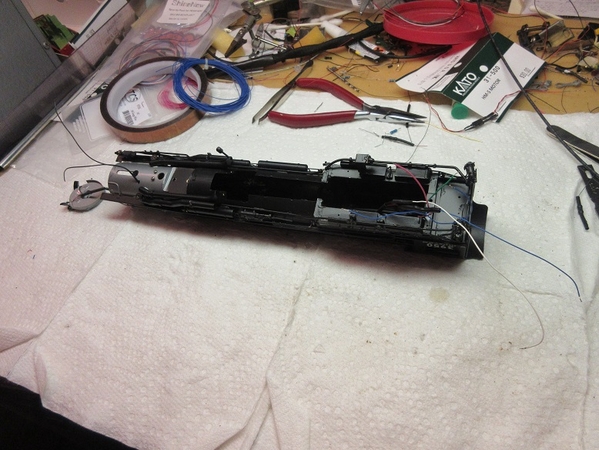

Steve discussing stripping his hudson with Jor.

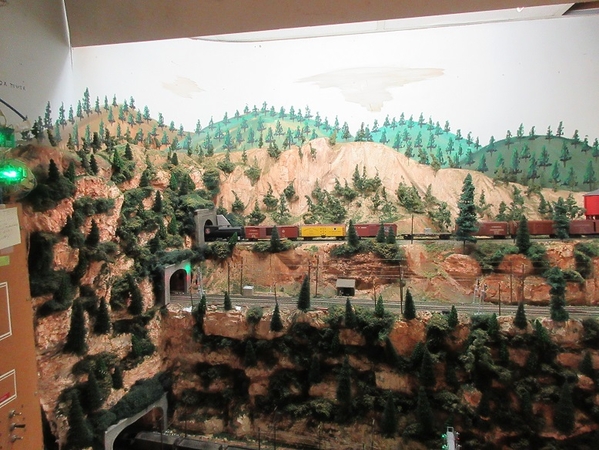

Bob's AC-9 west of Waverly.

GN R-2 just east of Wilmar.

Bob's AC-9 waiting for John's GN N-3 2-8-8-0 to free up the mainline at Waverly.

Jor's M-1 in the hole until Joe's new SP black widows pass at Tye.

Joe likes his SP black widows by BLI. With 3 of 4 units with power, he figured no problem just pulling one full string of 43 cars out of one freight track.

Jor the first in with multiple mainline trains following him.

John's GN N-3 just west of St. Paul.

John's GN N-3 heading for Waverly.

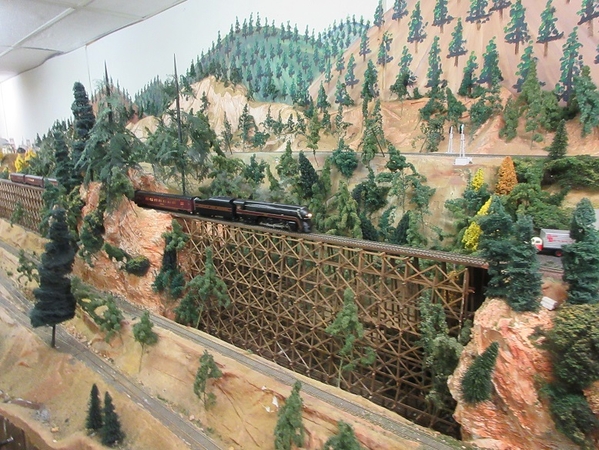

Joe's black widows about to enter Chumstick Canyon trestle.

Dave's GN R-2 at St. paul.

Joe's black widows in the hole until Bob's AC-9 passes.

Old versus new : AC-9 passing black widows.

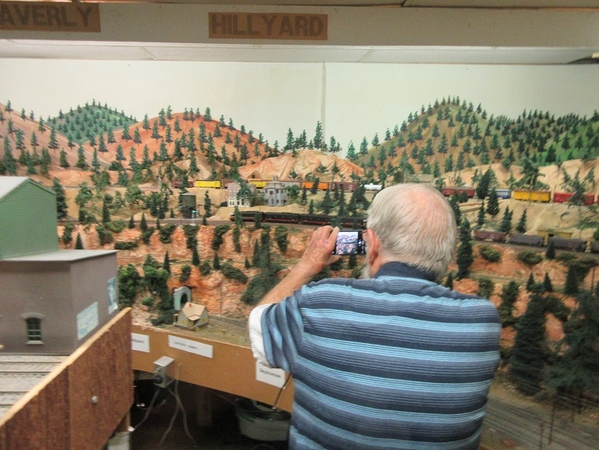

As usual, as seen by all the red on the dispatcher's panel indicating train locations, I was kept busy trying to prevent 'corn field' meets!

Bob's AC-9 at Marias pass.

AC-9 at Skykomish.

Joe doing some dispatching (routing trains) while running his black widows.

Bob's AC-9 dropped off his train and heading for the roundhouse via escape tracks.

Fortunately, after Jor finished running the M-1 turbine, he took over yard hogger duties.

GN R-2 passing black widows at Marias pass. Only had one SP cabeese and it was on the AC-9 so a UP was sub'ed!

AC-9 getting ready for servicing.

Dave's GN R-2 at Tye.

St. Paul yard.

Joe's black widows at Tumwater canyon trestle.

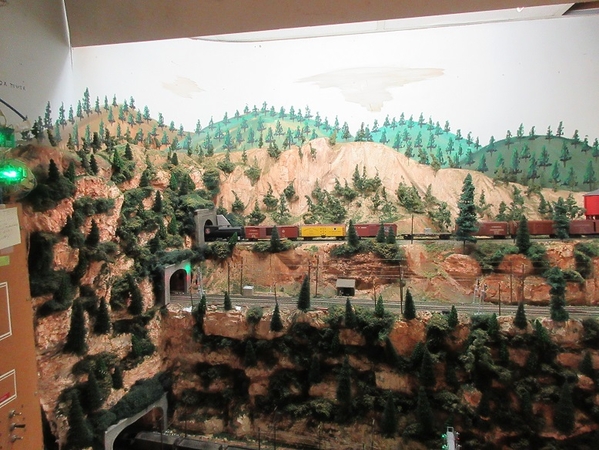

Maria pass.

NYC Niagara 4-8-4 passenger train at Wilmar.

After a hard day's work an orange cream cycle is a welcome sight!

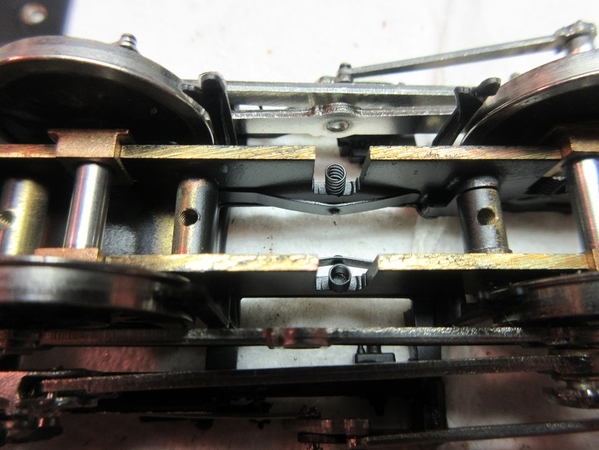

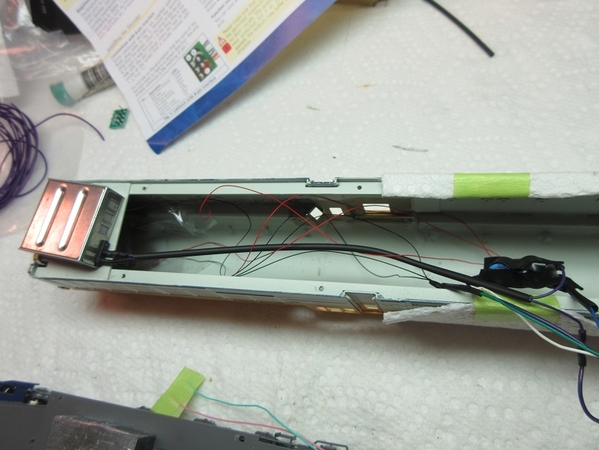

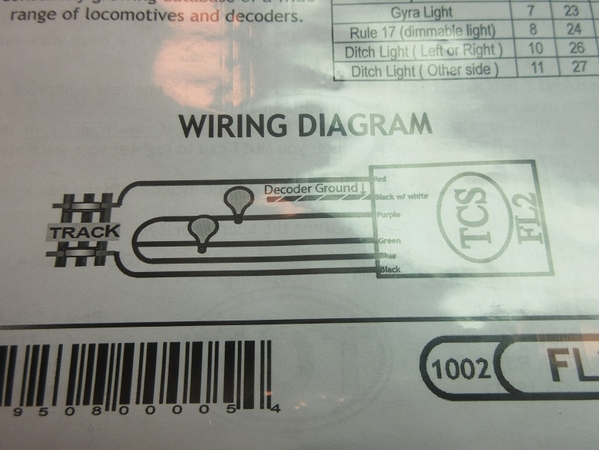

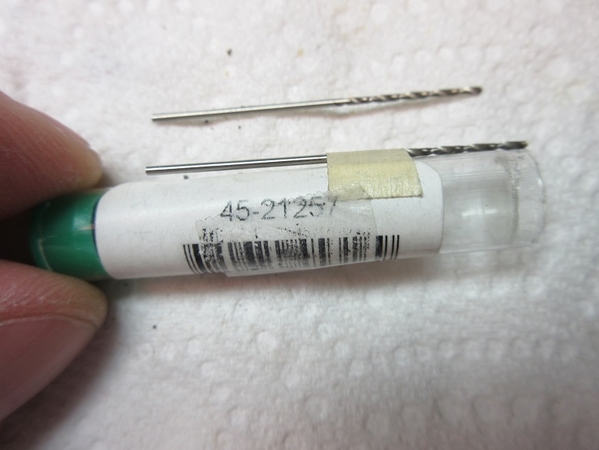

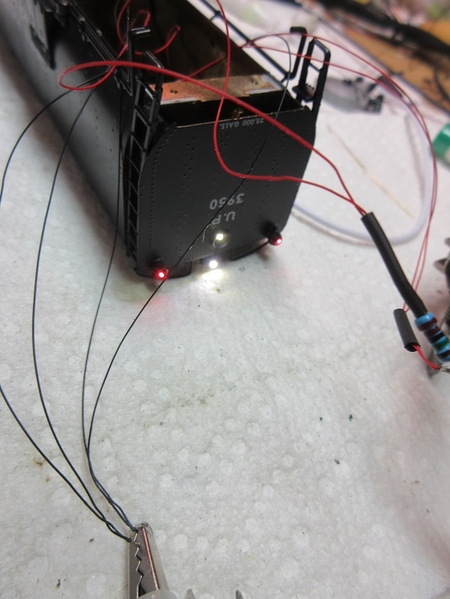

The lights were turned out around 1:30 AM: no world problems were discussed or solved but we did a lot of 'train talk' and did a little resistance soldering on Steve's brass engine that had a part come off.