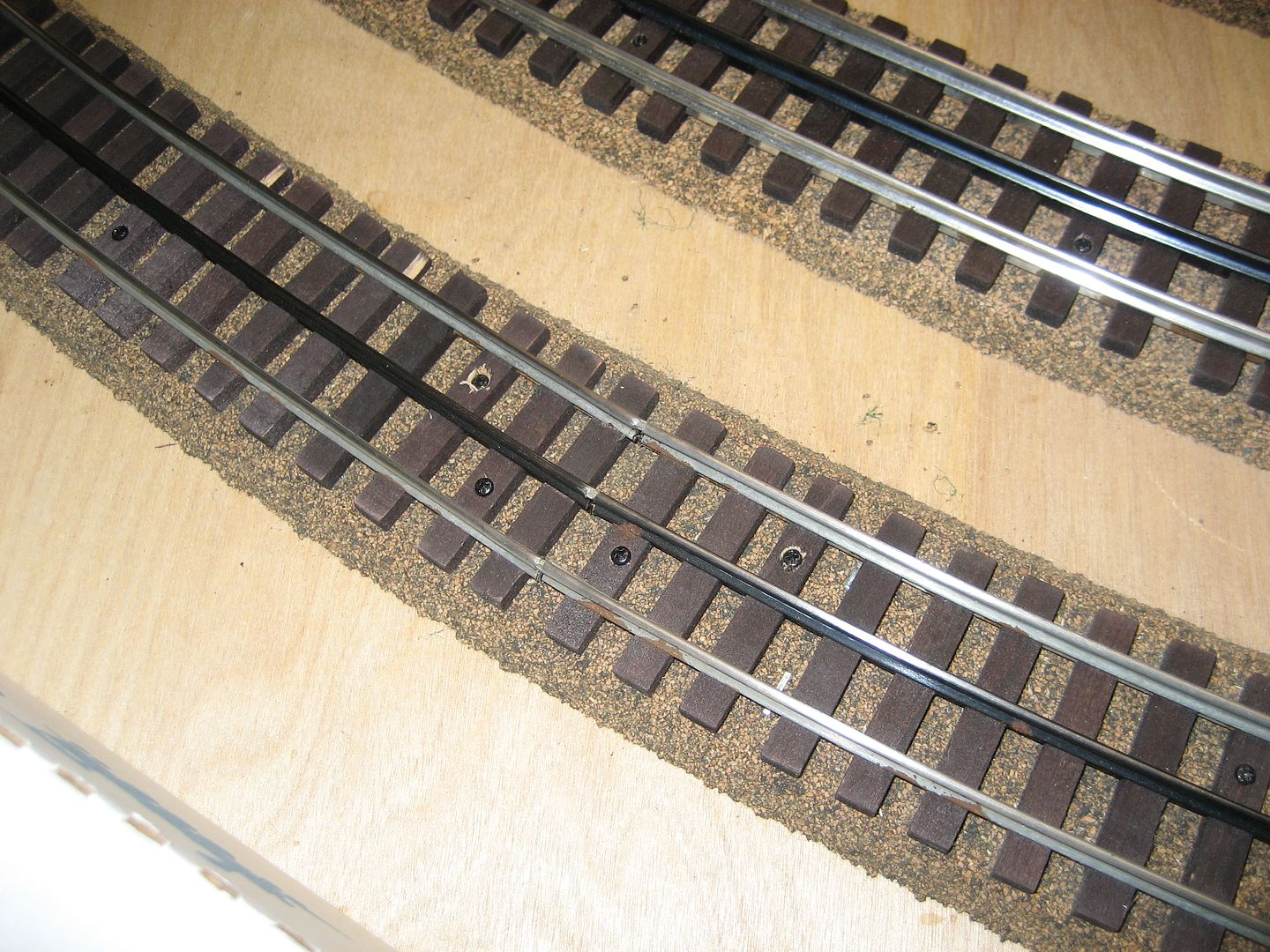

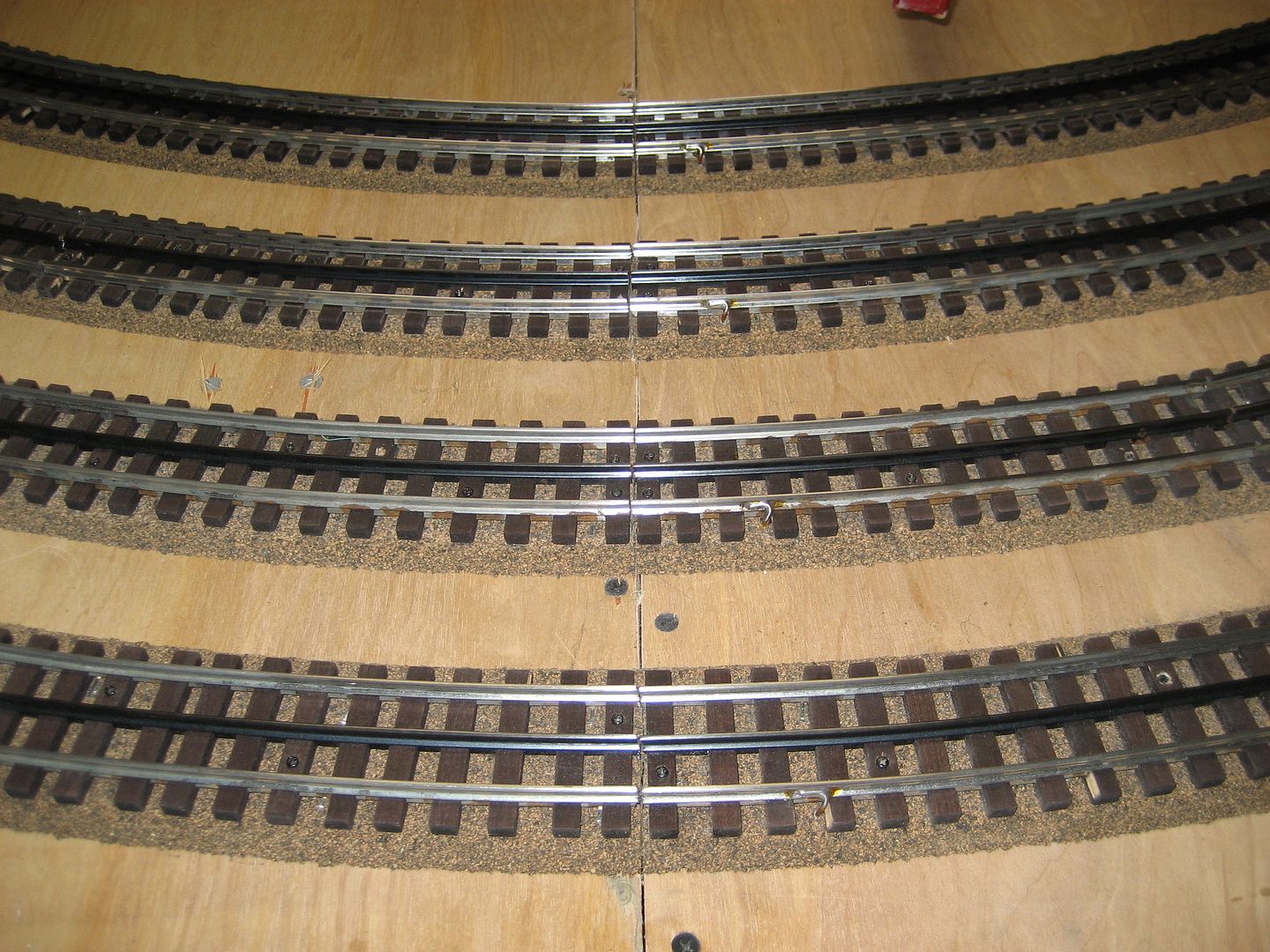

As you know, there are six holes in each piece of O gauge track for fasteners. In laying out my track for testing, I have been putting only two #4 screws in each section to hold it down on the plywood, one in each tie on the end, with the screws alternating up and down (zig zag).

With just the two screws, the track is rock solid down on the plywood. I can't budge it at all, or lift any ends to adjust.

Do you guys really put 6 nails or screws in each track section? How many do you use?

Thanks,

Mannyrock