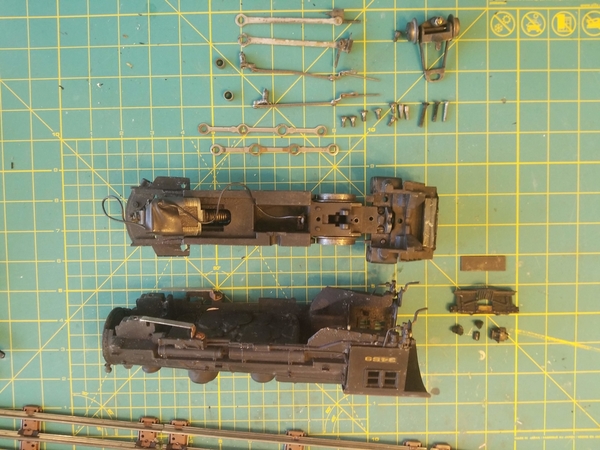

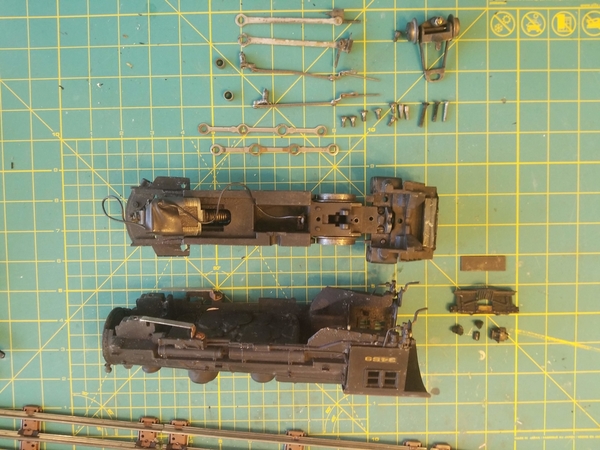

@Dave Funk: You nailed it. I got it in the mail today and proceeded to tear into it. It is indeed an old Lionel engine with all sorts of brass add-ons.

I've already torn it all the way down to the bare bones, including taking the motor apart to clean up what appeared to be a collection of gravel, concrete and old Fork V8 motor blocks in there. Well, not really, but it was not pretty inside.

It is indeed a DC motor with a permanent magnet. It had a hard time turning freely on account of the gunk, so I actually physically removed the armature and yanked all the stack plates and gave everything a nice mineral oil bath and scrub. Also polished up the brush commutator, although it was actually in decent shape as were the brushes.

The modeler before me milled out for the worm gear to mate with the motor, but there were a few problems. The milled-out area wasn't wide enough for the gear, and the worm was ever-so-off-axis, so when I manually turned it, it would grab one or two teeth on a tiny corner once per rotation. I was just able to get in there with the tip of my dremel and knock that corner off. I also re-seated the gear and centered it up better, now there's plenty of clearance.

Second, the motor was mounted to a custom brass wedge that then mounted to some machined holes in a milled-put area at the back of the frame in the cab. However, the wedge wasn't at enough of an angle, and as a result the output shaft sat too high and the worm teeth wouldn't mesh consistently with the gear so every once in a while it would skip a tooth. (I did this all manually with no power, didn't want to apply any juice yet). That was easy enough to deal with by adding a very thin shim to the rear portion of the wedge to force the output lower and now it meshes all the way into the gear!

Third, the existing power input to one of the brushes was soldered very poorly, and vibration would make some of the strands contact the motor frame and would almost certainly have grounded out the motor and not allowed it to operate. Instead of just re-soldering the wire, though, the previous owner tried to combat this by shoving some tape between the terminal and the motor frame. Btu the tape was worn through and it wouldn't have been effective. So I pulled them off and re-soldered new wires after cleaning the brushes and terminals thoroughly.

Lastly, the input roller assembly was grounding against the lower part of the chassis where the feed wire passes through. The owner cut some braided jacket and tried to shove it around the feed terminal, but the jacket is too short and the exposed terminal could tap-tap-tap the chassis. So I ripped that out, re-soldered and straightened the jacket, then taped it off for now until I can heat shrink around it.

I've started stripping the paint from the brass pieces. The brass add-ons at the front end broke off during shipping, looks like they were glued with a thick layer of glue before. I've spent some scrubbing time stripping that glue residue and trying to get the paint off. Still working on that. Godd news it appears that ALL pieces are accounted for, all the piston rod screws and piston rods seem to be present. Although they need a serious cleanup and polish.

My biggest conundrum right now is how do I affix the QSI ACRU-lp to the DC motor? (photo attached below) The motor has only two leads (+ and chassis ground). I can't see any sign of a rectifier on the reverse unit (there wouldn't be since it's an AC reverse unit). So can I wire the leads to the legs of a bridge rectifier and then out to the DC motor? In other words, treat the bridge as if it was the AC motor and then send the + and - outputs of the bridge out to the two brushes on the motor? This is my biggest challenge ATM....

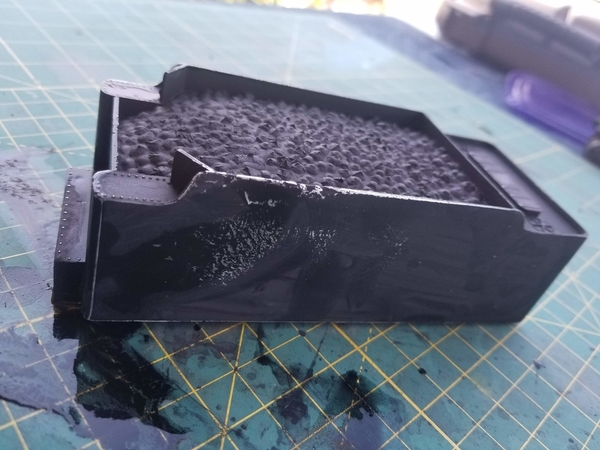

By the way, the reverse unit actually fits in the boiler but only AFTER I removed about 60% of the lead packing that was up in there. Seriously, this thing weighed like 18 pounds before I pried layer after layer of hammered lead out of the boiler. It still weighs a TON, but now I can fit the reverser!

By the way, and this drives me nuts, the original owner actually did a decent job on paint (although you could tell it was painted with the wheels and motor in place), but the cab is actually noticeably crooked! Oh well, once I get this mechanically and electrically rolling, maybe I'll try my hand at refinishing the exterior. I've stripped the brass so it's going to have to happen sooner or later!

Anyway, on to the photos!

Everyone's accounted for!

Brass front end fell off during shipping:

SO MUCH LEAD!!!! I think I need to file paperwork with the EPA when I sell my house now...

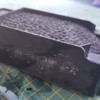

Pretty rough, and ( + ) terminal shorting intermittently

After a bath!

You know what really grinds my gears????

Rolls pretty nice after a rebuild of the chassis and axles!

View of the milled-out areas after everything got cleaned up.

Together again! And a NEW FRIEND!

Any advice on how to hook this AC reverser to the DC motor? Just through a bridge?

AAARGHH! (Yes, it looked like this in the auction website photos. Still aggravating!)