I have never done isolated rail thing, how long does the isolated rail have to be and how far from the grade crossing protection can it be ? Also will this work with Z Stuff?

The insulated rail can be any length, and it can also be in any position. It really depends on what you're using the signal capability for. We have some on the club modular layout that are 20-25 feet long or more, they protect a couple of long tunnels that otherwise we could have issues if someone stops or gets stuck in there. There's a signal at the entrance, and right past the signal, the insulated rail starts until the tunnel exit We have some insulated rails that are shorter and are for crossing signals.

Probably just a try would be sufficient for me, don't think I would want a steady diet of SMT to assemble. Sending those out sounds like a good plan to me. I am amazed at how small things can be made with SMT.

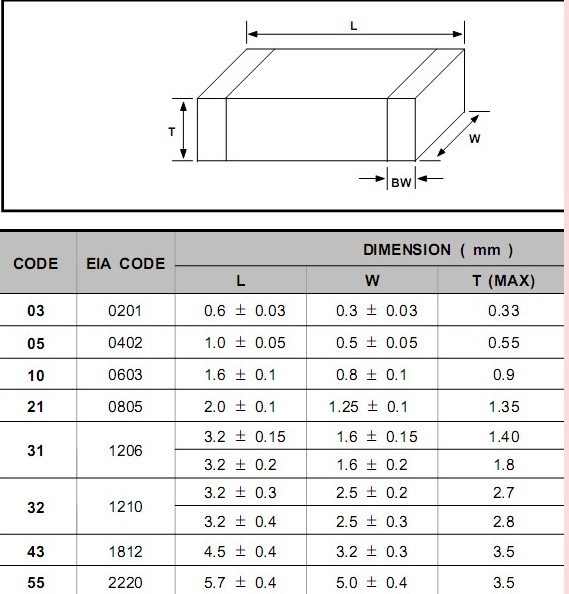

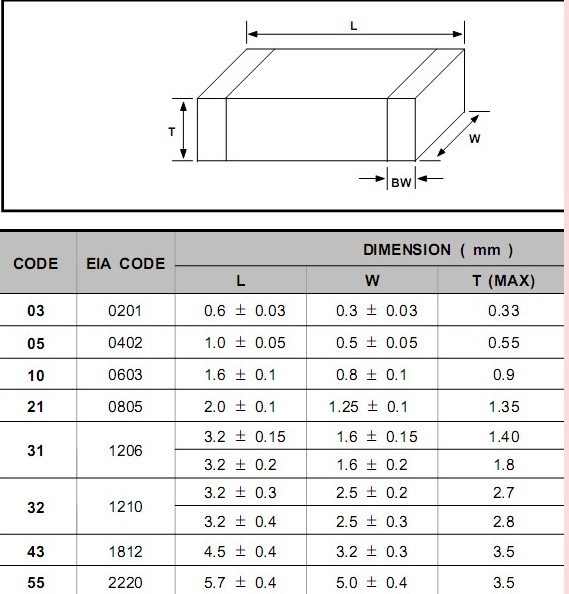

Yep, I only assemble what I need for prototypes or small low count projects. I also have learned quite a bit about laying out a design for easier hand assembly. Positioning the parts for easy soldering, and also picking sizes that are reasonably easy to handle are key. I did one design early on and I specified a size 0201 resistor! I don't don't know if you realize how small a 0201 resistor really is! Check the table below! I couldn't even see to position it using my desk magnifier, and forget about soldering it! I've since set a self-imposed lower limit of 0603 parts with a preference for 0805 or larger. I also steer clear of any multi-pin part at a spacing of less then about .095mm between pins.

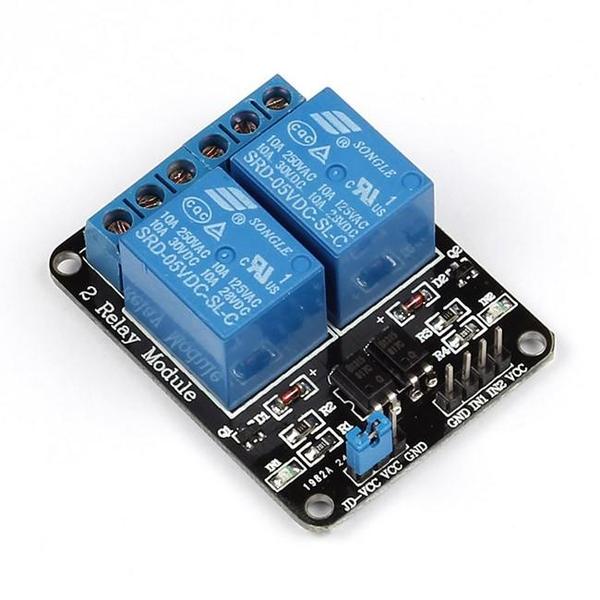

I think the time delay suggestion above might open the door for another module, but I think you are right to keep these simple and as they are. I think there would be many more users that way. You could add the time delay, larger relays, flashers or whatever in separate modules later if the demand is there. A modular system so to speak.

There's always room for a future product that does much more. If I went that route, I'd probably consider a uP based project to give me a lot of flexibility. A uP with a nice big jumper field for options would provide lots of flexibility, but it would also carry a higher price tag. There are always tradeoffs...