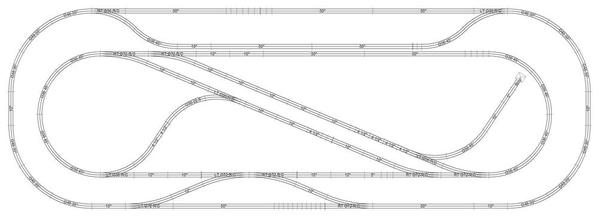

Hello all, this is my first post but I have been lurking on here for months now. My question to the experts is this; I am using SCARM software to design a fastrack layout and in a few spots I can only get to within a 10th of an inch making the connections. I have spent hours using every combination of connector pieces that I can. In the real world if there is a 10th of an inch gap in the track will it matter? There are a lot of switches in this layout and I'm wondering if that is what is causing the issue. I can't understand why a radius wouldn't connect perfectly. Any advice you have would be greatly appreciated.

Just wanted to update this post with the pictures of the finished product. Thank you all again for your design help it really made a big difference.

![FastrackDesignerTable[1] FastrackDesignerTable[1]](https://ogrforum.ogaugerr.com/fileSendAction/fcType/0/fcOid/70411412280701347/filePointer/70411412281019488/fodoid/70411412281019484/imageType/MEDIUM/inlineImage/true/FastrackDesignerTable%255B1%255D.jpg)

![FastrackDesignerTable[1] FastrackDesignerTable[1]](https://ogrforum.ogaugerr.com/fileSendAction/fcType/0/fcOid/70411412280701347/filePointer/70411412281019488/fodoid/70411412281019484/imageType/SQUARE_THUMBNAIL/inlineImage/true/FastrackDesignerTable%5B1%5D.jpg)