Figure I my as well start up my layout progress thread as parts are slowly arriving.

Got most of the track today minus the switches. Picture looks like not very much but there is about 100 foot of track there haha. Also decided to mask off the floor in the garage to get an idea on the size.

I'll be off to Menards this weekend to pick up the wood and it all will begin!

Going to be using Gargraves track with Ross Switches.

Big thanks to Moonman (Carl) for the help with the design and final touches!

I will try and keep you guys updated!

Replies sorted oldest to newest

Please keep us posted.

Those plans do look neat. I also used Gargraves track and Ross switches on my layout. Looking forward to more updates.

I like that proposed layout. Should be fun operating it. Lots of room for accessories, buildings and scenery. Good luck!

Please keep us posted.

Will do Spence!

Those plans do look neat. I also used Gargraves track and Ross switches on my layout. Looking forward to more updates.

Thanks, I really like how the track looks.

I like that proposed layout. Should be fun operating it. Lots of room for accessories, buildings and scenery. Good luck!

Thank ya!

Tomorrow I am off to Menards to pick up all the wood and the base will be starting to get built this weekend. The fun will soon commence!

Nice.....looking forward to updates.

Peter

Lance,

Looks to me like you mean business!

I'm looking forward to seeing your progress. Looks like you have a good plan and are buying quality materials!!

Lance,

Looks to me like you mean business!

I'm looking forward to seeing your progress. Looks like you have a good plan and are buying quality materials!!

Thanks Mark! Figured id do it right the first time around haha.

It's always exciting when boxes of track and lumber show up! Can't wait to see your progress.

Lance

We will look for the build pictures.

I love it when a plan starts coming together.

Larry![]()

Looking good Lance, you are a good forward planner.

I probably missed it--but what type of switch motors are you planning and what type operating system[Conventional, DCS, TMCC?].

Power supply?

Looking good Lance, you are a good forward planner.

I probably missed it--but what type of switch motors are you planning and what type operating system[Conventional, DCS, TMCC?].

Power supply?

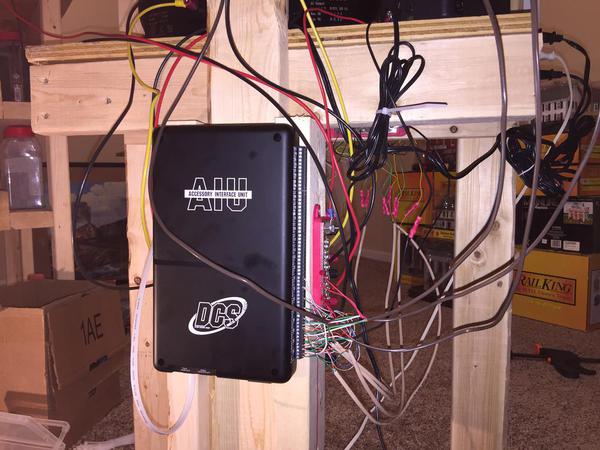

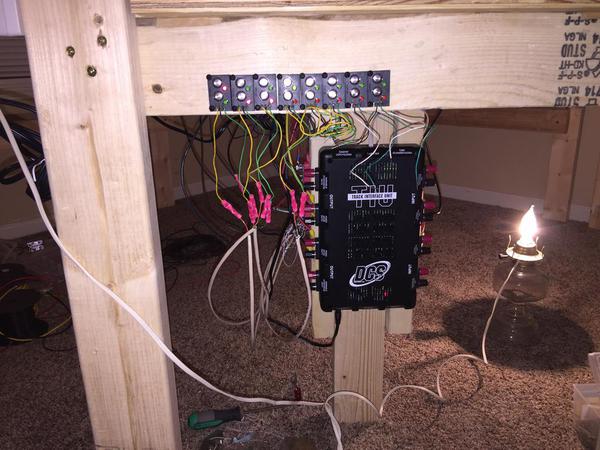

DZ1000 switch motors. I am going to be running the DCS system. Right now I am running it off a z1000 power supply. Eventually going to upgrade in the future to either 2 power bricks or a z4000. Haven't decided yet.

Sit on the floor and measure to the top of your head. Then add some clearance.

That way you can sit comfortably under the layout for the eventual under layout the time.

Also, if no littles are involved, a height of 40"-50" eliminates some of the helicopter view and improves viewing angles for adults.

36" is too low for you.

Also, if no littles are involved, a height of 40"-50" eliminates some of the helicopter view and improves viewing angles for adults.

36" is too low for you.

Though it's personal preference, I tend to agree with Moonman.

36" will wear you out crawling under it...repeatedly...

The legs should be fine if you add some angle braces from the top of the table. I agree with the others who like a layout higher, as it is easier to get under, and gives a view that is more like standing on a small hill trackside instead of in the helicopter, or drone as I've seen in some recent videos. My past layout was 48" high but when the kids were small, I had to hold them up to see the trains. If you have small children, you may want it lower as Carl inferred.

Make sure you drill a few holes to run your wire before you put the top on. You will thank me later.

I second Jmiller suggestion about holes for wires.

Get a large diameter drill bit -3/4inch or 1 inch and drill several holes in each cross piece under your plywood. It will make running wire much easier. I made this mistake and was drilling holes under the layout after the fact. And after drilling one or two holes - then I realized that I needed more holes - and the bigger the better ( not so big you loose structural support ) I have a modest sized layout but with track switches, track power, signals, UCS tracks and accessories. ( I have a lot of wire under my benchwork )

Steve

Thanks for the replies!

Another tip-don't brace the legs parallel to the floor. You'll get tired of crawling over them real quick...

Post pictures when you've made progress. Can't wait to see it.

Nice solid table. Did you do the "I have train table" dance on it to celebrate? Now it's time to nag the heck out of the heating contractor.

All of us can relate to the feeling you get when the table is completed.

Congratulations!

Lance-

I remember the great satisfaction I felt when I finished my benchwork. Congratulations!

Two comments -

1) I do not see holes drilled in the cross members for running wires.

2) Get some homosote or celotex sheets to cover the plywood. Get a gallon of cheap white latex paint and give them a base coat. ( both sides and the edges ) Then paint the top a neutral earth color ( Tan - Light Brown ) This will give a good surface for sound reduction and will hold screws well when laying track.

Keep up the good work

Steve

Great job!

Doing good Lance. ![]()

Out of curiosity is that drop down attic stairs above the layout?

Larry![]()

Nice solid table. Did you do the "I have train table" dance on it to celebrate? Now it's time to nag the heck out of the heating contractor.

All of us can relate to the feeling you get when the table is completed.

Congratulations!

Not yet haha. Still a few more braces I want to put in lol! And yes I'm getting antsy waiting on the heating people!

Lance-

I remember the great satisfaction I felt when I finished my benchwork. Congratulations!

Two comments -

1) I do not see holes drilled in the cross members for running wires.

2) Get some homosote or celotex sheets to cover the plywood. Get a gallon of cheap white latex paint and give them a base coat. ( both sides and the edges ) Then paint the top a neutral earth color ( Tan - Light Brown ) This will give a good surface for sound reduction and will hold screws well when laying track.

Keep up the good work

Steve

They are there. I took some of the pics mid drilling them. Battery was getting low on the drill so I had to charge it up a bit. Was going to paint it but haven't decided if I want to go a darker color or not. Thanks!

Great job!

Thank Ya!

Doing good Lance. ![]()

Out of curiosity is that drop down attic stairs above the layout?

Larry![]()

It's not a drop down, lazy builders only put a piece of drywall up there lol. But it's and illusion because the layout it about 8 inches away from it when standing directly under it.

Congratulations, Lance!!!

Lance,

As a former co-worker used to say, "Now you're cookin' and cleanin'!"

The table is up now and soon the fun will being.![]()

Looking real good. You've made very good progress.

Congratulations! Remember, few things worth a **** come easy!

So cool! Your layout is becoming a reality!

great job so far! keep up the great workmanship and you will have a layout to be proud of....

Lance, May I make a suggestion?

Stop where you are, cover everything with a tarp or plastic, and get out the spackling! Let it dry, lightly sand, then prime the wall. I won't go into all the details, as there was a thread about 4-5 months ago that covered this subject in detail. When the wall is ready, follow with a coat of cobalt blue. I know, it is a lot deeper than what you are expecting. But when you do your clouds, they will really pop! You may even what to think about what background you want, and get it installed or painted. Doing the wall now will be a whole lot easier than later, after you have everything up!

Also, check your lighting. Do you have enough? Again, much easier now than later.

Chris

LVHR

Chris' point is actually a very good one....if you're so inclined.

Sadly, my basement has poured concrete walls that are not painted but are off white in color. All the smoke that I "generate" gets lost with walls of that color.

Blue would be.....beautiful, IMHO.

I would paint the walls if the layout was going to be permanently here. I built the base to be able to take apart in sections and it will be moving to my new house that I am planning on purchasing next year. Great suggestions tho!

My basement also has poured walls. The walls were wrapped with a white plastic coated insulation. I bought steel studs and framed around the wall leaving the insulation in place. I might have lost six inches of room space, but I think it paid off in the long run. I added a drop ceiling and track lighting one one side. I only hung one sheet of drywall spaced low enough for the drop ceiling to cover the top seam and built a box beam for the bottom edge to rest on and support the benchwork around the wall. I figured there was no need to cover the bottom part of the wall since the bench would cover that area. Once I'm done I'll wrap the bottom of the bench with a cloth drap and no one will know unless they lift up the cloth.

Attachments

Lance, you've made a lot of progress (and you sure are putting the hours in) and the track work looks really good.

I may have missed it, but how did you decide to bend the Gargraves, or did you use sectional curves?

Lance, you've made a lot of progress (and you sure are putting the hours in) and the track work looks really good.

I may have missed it, but how did you decide to bend the Gargraves, or did you use sectional curves?

Outside was sectional track. The custom bends are in the inner loop. Will be getting to those soon...(not looking forward to it tho haha!)

Hoorah, heat!

I think it's time to put a set of jumper wires to the track and run a train. Play with some trains, umm...er...I mean check that track work.![]()

Great work! I had to teleport in and test the layout.

Amen to that! Hopefully I get good news for the heating stuff today. Torpedo heater is not my cup of tea smell wise haha.

My basement also has poured walls. The walls were wrapped with a white plastic coated insulation. I bought steel studs and framed around the wall leaving the insulation in place. I might have lost six inches of room space, but I think it paid off in the long run. I added a drop ceiling and track lighting one one side. I only hung one sheet of drywall spaced low enough for the drop ceiling to cover the top seam and built a box beam for the bottom edge to rest on and support the benchwork around the wall. I figured there was no need to cover the bottom part of the wall since the bench would cover that area. Once I'm done I'll wrap the bottom of the bench with a cloth drap and no one will know unless they lift up the cloth.

Video of NS on layout:

http://youtu.be/T60RZXoVnaY

I

My basement also has poured walls. The walls were wrapped with a white plastic coated insulation. I bought steel studs and framed around the wall leaving the insulation in place. I might have lost six inches of room space, but I think it paid off in the long run. I added a drop ceiling and track lighting one one side. I only hung one sheet of drywall spaced low enough for the drop ceiling to cover the top seam and built a box beam for the bottom edge to rest on and support the benchwork around the wall. I figured there was no need to cover the bottom part of the wall since the bench would cover that area. Once I'm done I'll wrap the bottom of the bench with a cloth drap and no one will know unless they lift up the cloth.

The styrofoam in the previous picture is Woodland Scenic's foam risers. The blocks on the other side of the bridge are solid 6" X 12" X 48" foam blocks I purchased from a company that makes foam panels and the 6 X 6 X 12" blocks I bought from an art supply place. My track rises six inches where the bridge crosses. I found out the hard way that six inches isn't enough clearance for a Double Stack Train. Luckily I only bought one car. The Woodland Scenic is a combination of two inch and four inch riser sets. I put four of them side by side to get the desired width to fit the double track profile. After this photo was taken I covered the risers with one inch green foam cut to fit the curve. I covered everything with a product called Fibatape Super Crack Stop. Home Depot sells the stuff and it comes in a roll that is 36" wide X 50' It is the same type of material they make fiber drywall tape out of. I used it to give the plaster something to stick to. Once I covered all the flat surfaces with the mesh, I covered everything with a skim coat of Gypsolite. After it dried I painted the surface to seal it. I used it too fill in some voids between the foam boards and to add a little profile to the edges of the risers. On the other end of the layout I had the company do some custom taper cutting on three 24" X 48" blocks. One was taper cut along the long edge from 6" to 4", another from 4" to 2" and the last one from 2" to 0". In the back left corner I put the 6 to 4 block and ran it down to two 2" X 24" X 8' pink panels. The 4 X 2 went down to the end making a 90. This went to a 2" x 8' pink panel and the 2 to 0 was added to the end side of this panel.

Attachments

I looked up a dealer for Polystyrene Foam and happened to find one that was twenty miles away. Check the internet for a company near you and see if they will cut some for you. It made the raised level very easy to construct.

Lance, It sure is coming along ![]()

Try the fastener isle at Home Depot or Lowe's. Look for trim screws near the drywall screws. They have a small square drive countersunk head. They worked well with my FasTrack.

Now, connect two wires, and run some trains! Have fun, Lance. We're all having fun,through you.

Richie

Now, connect two wires, and run some trains! Have fun, Lance. We're all having fun,through you.

Richie

Well put Richie!

The outside loop is wired and I got to run the NS around it! Felt like a little kid haha!

Here's the video: https://www.youtube.com/watch?...Pw0&feature=youtu.be

Congratulations Lance! It's looking and running mighty good!

Great Looking benchwork & layout !

What a great layout in the making. Beautiful track work and foam.

Have fun. Keep the pictures coming please.

Glad to see you're still working on the layout, Lance.

Suggestion: get some Avery labels and attach them to your wire pairs to identify the circuit; just write on them and attach, even if they will only be a temporary measure. Likewise, get some tiny zip ties to keep multiple pairs of wires segregated from other similarly colored wires, and add the Avery label. For longer runs, use multiple labels on the same wire pair; e.g. when you go through a riser, you may have multiple pairs of red and black wires and you'll want to know which circuit they are for.

Not too much to update you guys on. Right now I'm just knee deep in wiring lol and almost done with track power. Decided im going to go ahead and get a z4000 to power everything.

I notice you have some wire sag. Get some of the plastic U Brackets for mounting electrical conduit. 1 inch is a good size. Screw them to the bottom of the plywood where you think you want to gather up some of the wire sag. Use just one screw. The plastic is flexible enough that you can slip wire in and out - but will hold up the wire. Helps with wire management.

Steve

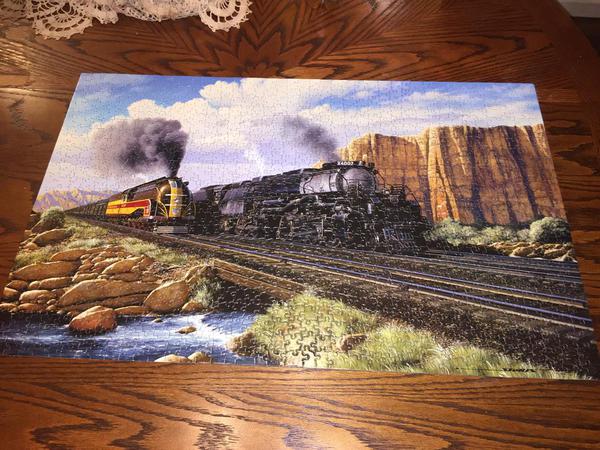

Looks like a UP 49er.

As 86TA355SR posted, it is the Union Pacific 49'er. Info and image below:

- The Forty Niner or 49'er, a streamliner passenger train between San Francisco and Chicago operated by the Union Pacific Railroad.

Image:

Nice progress!

Thanks for the update

Finished up the wiring on the inside loop tonight. Switches are the next thing up after I pick up my z4000 ![]()

Nice solid power, even with the small transformer. You hit it hard, from paper to trains running!

I would consider a control table on wheels or drawer glides to go under the table. I don't like the visual distraction of the power and control area, especially right in the center. You are running command, not conventional. Just my 2¢.

Bundle the wires and securing is no big deal. You needed them loose until it was all tested.

Nice execution of the build. You must feel good now.

Where's that heater guy before the Arctic Vortex rolls in this year?![]()

Nice layout and video! I'm new to this and trying to wrap my brain around the powering, are the dual trains running on one powered track and transformer?

Nice progress!

Thanks for the update

Thank you!

Nice solid power, even with the small transformer. You hit it hard, from paper to trains running!

I would consider a control table on wheels or drawer glides to go under the table. I don't like the visual distraction of the power and control area, especially right in the center. You are running command, not conventional. Just my 2¢.

Bundle the wires and securing is no big deal. You needed them loose until it was all tested.

Nice execution of the build. You must feel good now.

Where's that heater guy before the Arctic Vortex rolls in this year?![]()

Still brainstorming on where i'm going to put it. Just ordered the 4000 so hopefully it will be here later this week! I've been dragging my feet on getting that heater up out there haha. Holidays have had me swamped. Hopefully I decide on something soon!

Thanks Kon!

Nice layout and video! I'm new to this and trying to wrap my brain around the powering, are the dual trains running on one powered track and transformer?

Thank you Todd. My inside loop and outside loop are powered on 2 fixed channels on the DCS system. Each section is insulated into blocks and has power running to every 6 foot or so of track (from terminal strips that are fed from the Fixed Channels on the TIU). In the video, I just wired together both channels so I could run everything and make sure I was getting adequate power to everything.

Great job Lance. Track plan is well done and looks like fun! Have a great time with Big Daddy and thanks for posting!

JohnJr

I'm with William! You did it. I also agree, if it was me, I would cut in a couple of sidings before getting too far along. I mainly just like to watch trains run, but sometimes I want to do a little switching and have hopes of getting a log dump and sawmill some day. Maybe some other operating industry.

what did you spend on track for that size. looks like gargraves? or atlas? Just wondering because I may accumulate some of this type and ditch my realtrax. is this hard to bend to shape or do you use some sort of tool bender?

looks really cool!

Chris

what did you spend on track for that size. looks like gargraves? or atlas? Just wondering because I may accumulate some of this type and ditch my realtrax. is this hard to bend to shape or do you use some sort of tool bender?

looks really cool!

Chris

It's Gargraves with Ross Switches. I don't remember quite what I spent but it wasn't too bad. I bought some extra flex sections to practice with and bend. Some turned out okay and others I may redo. Just takes practice. As for the bender...I have a lot of money invested in it (my stomach LOL!) Thanks!

That makes good sense now that you explained. I will do the same thing, since I won't be able to buy all my track and switches at once. Get some trains running, then add the yard, sidings later.

If you said earlier you will be moving soon, I missed it or forgot. What are the size of the pieces of layout that you will be moving? Oh you're a young guy, you can probably pick the whole thing up and squeeze it through the sliding glass doors. ;-)

Not much to update you guys on, temp has been dropping here so I've avoided the garage a bit. Plus, been working 7 days a week to pay for my expensive hobby haha. Hopefully this coming weekend I can get all the switches wired up.

Good idea, and now I see how you constructed it in sections for moving. Very good!

I have a few supports to do under the table yet but pretty happy how it's sitting.

Also, I had to hack off 2 foot from the right side so I am redesigning the two curves on that side and moving the switches that were up front to the back.

It does feel nice to be inside and work on carpet!

Lastly, figured while I'm still messing with wood I would make a few model railroad "spice" shelfs. Also picked up this license plate frame yesterday which seems fitting

Attachments

Attachments

Attachments

Lance,

Movin' on!...bet you appreciate the carpet now.

I don't recall, did you get Ross ready or did you have wire for non-derail yourself?

Much nicer room! Coming along there.

Thanks for the update.

Just a quick video update...going to work on new sidewalks this weekend so I can start wiring and securing the buildings.

Layout update vid:

Lance,

Really starting to come together, very nice job! Now a 2nd & 3rd level engineering planning job is required.

PCRR/Dave

Lance,

Really starting to come together, very nice job! Now a 2nd & 3rd level engineering planning job is required.

PCRR/Dave

Yeah I definitely want a second level for sure!

Lance, I've really enjoyed your updates as you progressed from plan, to benchwork, etc. Thanks for the video.