Michael, I thought that would be the case. I haven't jumpered for the manual reset or wired in the reset switches yet. I got working on my liftup bridge, and once my mainline had two opening, I haven't bothered with more wiring.

Tonight I mounted and wired the final terminal block for track power. This one is going to power the yard, so I mounted it underneath the center of the yard instead of on the board next to the TIU, which is closer to the center of the other 3 loops. That way I will have shorter wire runs from the terminal block to the yard tracks. I also checked the voltage at each terminal block and they all checked out correctly. Over the next couple days I will probably set up a test track and test each terminal block connected to that with an engine to ensure I'm getting good dcs and tmcc signal.

Michael

Attachments

@Mark Boyce posted:Michael, I thought that would be the case. I haven't jumpered for the manual reset or wired in the reset switches yet. I got working on my liftup bridge, and once my mainline had two opening, I haven't bothered with more wiring.

Mark, I haven't had a chance to comment yet on your page, but I have been following your lift bridge project and it is impressive. You're doing a great job! I can't wait to see them when they are complete and operational! I'm sure you want to get that completed so your mainline isn't fouled up and you can run trains again without them falling off the cliff 😁.

Michael, I can’t wait either. Getting everything lined up right on the lift bridges is a little tricky for me! Yes, I took a break from the bridges to fix a minor problem on my most expensive engine. I did a test run very slowly, and went into Advanced on the DCS remote. Then I tried to slow down without getting out of Advanced. Of course nothing happened. 😱 As I moved over to break a fall, I fumbled to the right place and stopped the engine with 3 or 4 feet to spare. 😊 It was a wake up call to continue on the bridges exclusively until finished.

I just wanted to say Happy Memorial Day and thank you to all the courageous men and women that have sacrificed and gave their lives for the freedom’s we have here in America!!! In honor of them, here is a short video of my freedom train on a short section of the layout in progress. Thank you!

Michael

Attachments

Hello,

Just a quick update to show some of the progress I have made in the past couple months. Progress has been slow because during the summer, much of my free time is dedicated to outdoor yard work and family. Nevertheless I have been inching away at it when I have time.

I have rough laid the lower level double main line and reversing crossover. All the track is screwed down so that I could get all the flex track pieces bent correctly. This was a lesson for me in cutting and bending gargraves track. I am pleased with the results. All the curves flow together nicely and so far I have not wasted any flex track pieces 🙄. The next step for this track is to put down the roadbed. I know I am doing things backwards but I wanted to make sure my track layout was solid first. I am going to attempt to slightly lift sections of track piece by piece enough to get the roadbed in place and glued down without having to remove the track completely. After the roadbed is down I will probably wire this section up so I can actually run trains somewhere. Then I will probably start figuring out my grades to the upper level and work on laying out the yard as well.

I will leave you with some pictures of the layout with a bunch of different train consists to give you a flavor of what I will be running on the layout. Obviously I won't have all these trains running at the same time. I setup the tunnel portals so you can see where the trains will traverse under the upper level once it is in place.

Happy 4th of July!!

Michael

Attachments

Michael, It looks like good progress. You had more success bending GarGraves track than I did. Congratulations!

Michael, well done!

Peter

Good Evening,

Today I completed the track work on my lower level double mainline, minus the ballasting which will happen at a later time.

I used a somewhat different method than most folks, but it seemed to work well for me. I will detail the steps below.

I used a somewhat different method than most folks, but it seemed to work well for me. I will detail the steps below.

Most people transfer the track plan to the table by marking out the center line of the track with marker. They then use the centerline to lay out each half of the roadbed and finally they lay the track on top of the roadbed.

I started by roughing in my track plan on the table with pencil. But because I had several custom bent curves, I wasn't sure exactly how it would lay out. I wanted to make sure that all of my curve and turnout transitions flowed seamlessly into each other and that my track plan would fit properly on the table. So I decided to lay the track out first, screwing down sections as I went and bending the curves so they would flow nicely. Once I had all the curves bent and all the track layed out and roughly screwed down, I then marked both edges of the track ties with marker. This was to make sure I knew where the bent curves should lay when I removed the screws.

After the track was all layed out, I went back and started laying roadbed under the track. I used a combination of foam Ross Bed under all the Ross switches and crossover and Midwest cork under the rest of the Gargraves track. I started working section by section, removing the track screws, raising the track up enough to slide the roadbed underneath and then rescrewing. I started with the Ross Bed for the switches. This product comes as a tan, yellow or pink foam. I decided to paint the Ross Bed before laying it down. I used Krylon foam safe primer and 2 coats of Krylon speckled stone spray paint in the pebble color. They ended up being a grayish brown. After the Ross Bed was painted, I slid each piece of Ross Bed under the appropriate Ross switch and pressed the switch down into the Ross Bed. It formed a very snug fit and I did not use any glue. Once all the Ross Bed was in place, I used the same method for the Midwest Cork working my way around the Gargraves track. I unscrewed a section of track. Then I put dots of white elmers glue in between the track ties on either side of the center rail every 12-15 ties or so. I slid the two halves of roadbed under the track (one piece on either side). The glue helped to hold the roadbed in place. I held the two halves of roadbed together with my one hand making sure they were aligned on the track while I screwed the track down. I used thumb tacks to help hold the roadbed in place in areas where there wasn't a screw or at the end of a piece. After a section of roadbed was complete, I ran a bead of white elmers glue along the edge of the roadbed and the table. After the glue was dry I removed the thumb tacks. This method seemed to work well for me especially after I got the hang of it.

I am pleased with the results so far. I have taken a lot of time with the trackwork, but I want to have a very good foundation for everything else and not have issues later on.

Here are several pictures of the progress so far. Next I will be working on wiring all this track up permanently so I can have a fully functional double main line 😁! I have waited a long time to see trains running around the entire loop.

Enjoy!

Michael

Attachments

Everything looks good man. Great track work and very neat work overall. Keep the progress coming.

Dave

Your track looks great, Michael! I laid out track and marked the edges too. Then put down the roadbed and track

Looks really good! I see no switch machines. Did you decide on under table mounts?

@turkey_hollow_rr posted:Looks really good! I see no switch machines. Did you decide on under table mounts?

Thank you Dave, Mark and turkey hollow rr for the kind words!

I have not added any switch machines yet. I have the DZ1000's for all my turnouts, but that is another project I will work on in conjunction with wiring up the track. I still have not decided if I am going to mount them topside or under the table. My original plan was to mount them under the table to look more realistic. But, I also want solid operation. I'm not sure if it is worth the hastle of trying to mount 30 switch machines under the table. If there are any thoughts on one vs the other, I would love to hear! Thanks.

Michael

Michael, for me, it is not worth the hassle mounting them underneath. I probably wouldn’t get them lined up right anyway! 😄

I can say with 98% certainty that they won't be as reliable under the table without a lot more fiddling!

I can say with 100% certainty that mine wouldn't be as reliable under the table no matter how much fiddling I do. ![]()

On top of the table, they are very easy to get right!

@gunrunnerjohn posted:I can say with 98% certainty that they won't be as reliable under the table without a lot more fiddling!

Thank you gunrunnerjohn. That was pretty much my conclusion from what I have seen and read. I want solid operation and am willing to sacrifice a little realism to achieve that.

Well done, Michael!

Peter

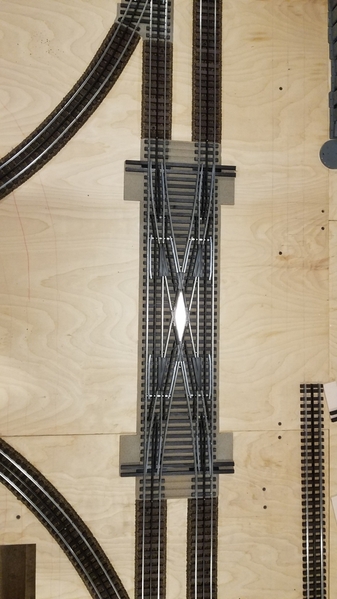

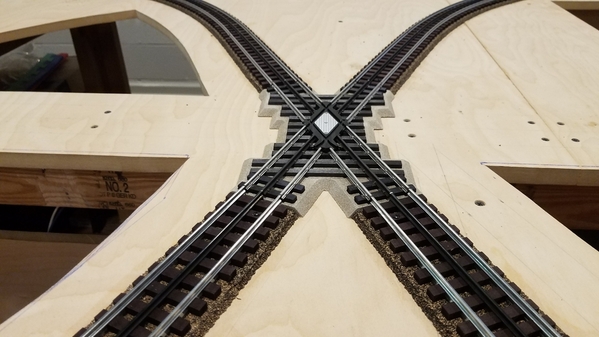

Is that a #6 double cross over?

@Tom Tee posted:Is that a #6 double cross over?

Tom Tee, it is a #175 Ross Crossover from their Super line. I have 2 of them on the layout

To all those that lost someone or were affected by the tragedies of 9/11/2001. We will never forget!!!

Attachments

Good Evening,

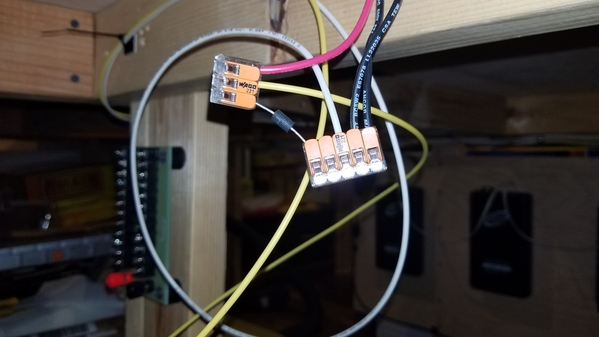

I finished wiring the outer main line. It consists of 7 track blocks wired in the star pattern using DCS. I soldered my leads to the rails of the gargraves track and ross switches. I cleaned off the plating on the center rail using my dremel cutoff wheel. I cut 8" 16 gauge feeder wires for the center rail and both outside rails. I tinned the wires and the track first. Using a soldering gun I was able to heat up the rail and wire hot enough to get a good solder joint. It took a few tries, but once I got the hang of it, it went fairly smoothly. I ran 14 gauge wire from the terminal block to each feed location. I connected those wires to the feeder wires using Wago connectors. They seem to work very well and have a nice tight connection. I installed a TVS diode at each track connection. I still have some cleaning up to do on the wiring but the outer loop is functional. I have included some footage of one of the first runs on the loop. It is a coal drag consisting of Western Maryland Challenger #1204.

Hope you enjoy!

Michael

Attachments

Congratulations, Michael!

The panel looks good and the train runs great!

@Mark Boyce posted:Congratulations, Michael!

The panel looks good and the train runs great!

Thank you everybody for the likes! Mark, my wiring doesn't look as good as yours......yet, but it is what I'm striving for 😉!

Michael

Michael, as long as you document or tag all your wiring, it doesn’t need to be extremely neat. The underside of my layout has wires crisscrossing each other. I wanted that to be more organized, but getting under the layout was harder after surgery. So, it isn’t as neat as I had hoped

The temporary Christmas layouts that I built when I was younger had wires everywhere under the table. It definately looked like spaghetti. Granted I was only running conventional so the setup was simpler, but I knew where everything went. With this layout I am trying to keep everything as neat and organized as possible. Most people won't ever see what's under the table, but I will know....😁

@Mark Boyce posted:Michael, as long as you document or tag all your wiring, it doesn’t need to be extremely neat. The underside of my layout has wires crisscrossing each other. I wanted that to be more organized, but getting under the layout was harder after surgery. So, it isn’t as neat as I had hoped

Mark, I can definately understand about your back. After I spent a couple hours crawling under my layout doing wiring, my back was definately letting me know it was there. I'm very glad you are feeling good enough to do great work on your layout!

Michael

Looks great, glad you're able to start running trains! ![]() Just starting the planning phase of my future layout after moving into a new place Memorial day weekend. Will keep following your progress!

Just starting the planning phase of my future layout after moving into a new place Memorial day weekend. Will keep following your progress!

Mike that wiring looks beautiful. Everything is coming along very nicely.

Well done!!!!!

Peter

Thank you Fridge56Vet, E-Unit-79 and Peter!

Fridge56Vet: I was where you are about 2 years ago, in the planning phase. I spent a lot of time planning because I wanted to create a solid, well thought out layout. The great folks on this forum were invaluable in helping me with ideas and answering all my questions. I would highly recommend contemplating their suggestions as you go along. One can't foresee everything that's going to happen and you will certainly run into problems that you didn't anticipate as you go along, but the more time you take now, it will be worth it in the long term. I wanted to get to this point so bad where I could run a train the wholeway around a loop, but I'm glad I took my time and didn't rush things. I don't have tons of time to work on the layout, but it seems like I hit a milestone every couple months. I have to remind myself it is a marathon not a sprint. Looking forward to following along with your layout!

E-Unit-79: Thank you! I'm just trying to take my time and do my best. Every step is a new learning process. Once I get the latout complete I might know what I'm doing 😉.

Peter: Thanks again! Those PRR coal cars in the video I picked up at York. It was a great time there!

Well over the past 2 months I put the big layout on hold for a bit while I built a 4 x 8 Christmas layout with the kids. It was a lot of fun!

I just put the finishing touches on the other day. I made a fun video showcasing the layout a bit. Hope you all had a Merry Christmas and I wish you a blessed New Year in 2022!

Michael

Michael, the Christmas layout looks great! You crammed a lot of action into 4x8! Have a blessed new year!

Very nice Christmas layout, Michael. The snow effect was great, but I really loved that you seemed to have found the perfect speed for the trains - not too fast... not too slow...

Happy New Year to you and your family!!!

Thank you everybody! It was a joy to be able to put this together. The kids had fun helping build the layout and running the trains. I'm hoping that excitement continues with them. My wife was responsible for getting the white felt base at the fabric store as well as some of the actual snow and she helped the kids put out the people and accessories. It was definitely a joint family effort.

Mark, yes we did try to pack a lot of action in to a 4 x 8. I wanted it to look full and busy but not overdone. It just so happened that all the Christmas/winter buildings and accessories I have fit nicely on this size layout.

Apples55, yes I was happy with the speed of the trains. I set them at the speeds I thought they looked good and then just let them run while I was filming. I think they naturally slowed down going around the curves and sped up on the straights which lent itself to some nice variety on the close-up shots. I did adjust the speed for a couple of the shots.

If anyone is interested in the technicalities of the layout, here are some of the details. I used a white plastic folding table as the base with a 4 x 8 sheet of 1/2" plywood raised above the table top with notched 2 x 2 blocks to allow for wiring underneath. I built a small control platform that I screwed to the end of the table while also supported with 2 legs. This is a conventional setup. The inside loop is Lionel fast track powered by a MTH Z1000 transformer. The inside loop has 2 feeder wires. The outside loop is Lionel tubular track powered by a MTH Z1000 transformer. The outside loop has 4 feeder wires. The trolley track is MTH Real trax powered by a Lionel starter set transformer. It has 2 feeder wires. All of the Christmas buildings/accessories are either 120V AC powered or battery powered. The 2 Lionel crossing signals and the Lionel semaphore signal are powered by a Lionel 1044 type transformer at fixed 16V. They are activated by the spring under track device that comes with these accessories. I used 14ga bus wiring for all track power and 14ga bus wiring with 18 ga feeders for the Lionel accessories. I used Wago connectors to connect all the feeders to the bus wiring. I used a TVS at every track connection. All 3 track transformers have additional 5 amp fuses for extra protection. The RS3 engine is a Lionel with dual can motors, smoke and Rail sounds but not TMCC. The Pennsylvania steam engine is from a Lionel Pennsy starter set. It has a can motor with an electronic E-Unit, smoke and an air whistle in the tender. The lighted boxcars and flatcar are MTH. The freight and passenger cars are Lionel and the trolley is MTH.

Michael

The Christmas layout is well done!

Thank you for sharing it!

Peter

Hello,

I finally got the 2nd main line wired up a little while ago. I have been playing around running different consists on the layout. Here is a short video highlighting 2 freight consists I have been running featuring an MTH Railking Imperial PRR M1 Mountain and an MTH Railking Imperial WM Challenger. The cars are a combination of Mth Premier, Mth RailKing, Atlas and Lionel. I have been arranging the cars in different orders to see what looks the best to my eye. I have been pleased with how smooth the trains run on the Gargraves track and Ross Switches. Next up is to install and wire up the DZ1000 switch motors on the Ross Switches as well as lay out the yard tracks.

Enjoy!

Michael

IT's great seeing two trains running on the layout, Michael!!

Michael, I love what you have done so far. Please continue to post pictures of your new layout.

Well done, Michael!!!!

Great video!!!!

Peter