Boy, if you can get electricity for 10 cents KW/HR, you're doing a lot better then I am! I live in PECO country, it's around 15 cents.

I didn't actually take all the measurements and log them, but I was taking a few. At the 2 minute mark the voltage was 3.6V across the caps. When "fully" charged after a minute, the voltage was 4.95V across the caps. That was from a full discharge, I didn't do any additional measurements. The lights remained on slowly dimming for over five minutes. The resistor I was using was a 39 ohm, but I think I'd cut that to the 33 ohm for the "production" version.

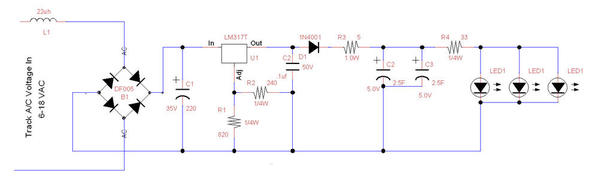

If you have three LEDs, the parts list is one 5 ohm 1W resistor, one 1N4003 diode, two 2.5F 5.5V supercaps, and a 33 ohm 1/4W resistor. You'll need the adjustable 5.5VDC 1A power supply to provide the power. Since the peak power is only for a short time, you could do this with an LM317T, diode, cap, and a 22uh choke for DCS compatibility. You can also do it with the canned power supplies we routinely point out on eBay.

Like I say, this isn't a "perfect" solution, but IMO it looks pretty good, it's dirt simple, and pretty inexpensive as well. For more LEDs, you can add a couple more super-caps. Obviously, that will extend the "full" charging time, if you have a reasonable charging time between the station stops, I think it should work out.

My advice would be to do a test run with one set of components and see if the results are satisfactory.