Panhandle 1 had a relatively (let's be honest  ) useless yard below the western end of the layout. It was reached by a long, steep, difficult lead. I don't recommend that approach.

) useless yard below the western end of the layout. It was reached by a long, steep, difficult lead. I don't recommend that approach.

Panhandle 2 has its staging on the same level as the layout. Staging is reached through a backdrop divider.

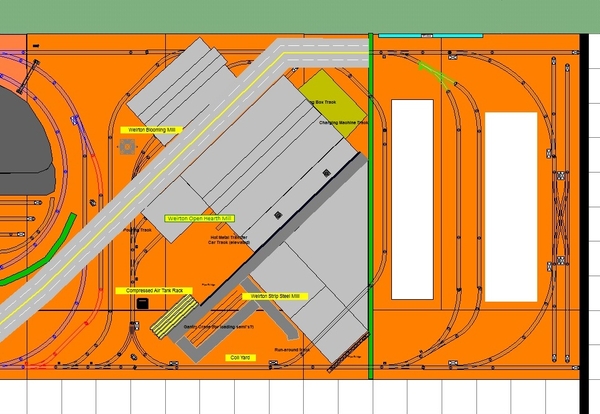

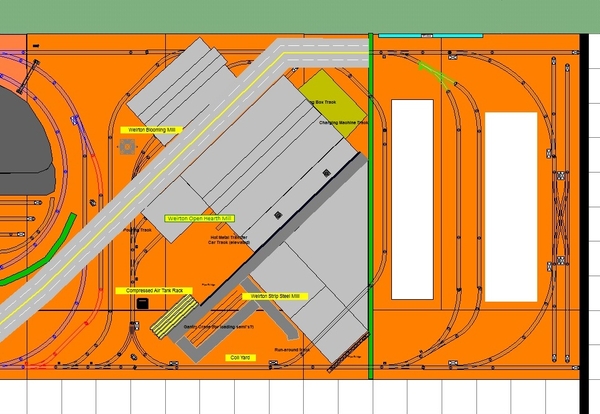

Behind the divider lies the Staging Area. When I am exactly sure of the track placement, I will cut 4 holes in it for trains to pass back and forth. Here's the track plan. The green vertical line is the backdrop divider. The holes at the very top and bottom of the diagram provide access to the staging yard. The other track is for interchanging steel-related loads and empties (coal, coke, slag, torpedo, finished products). As some point in time (God willing), it's my plan to operate the Panhandle with a crew of people. The white spaces are openings where the Staging Area Operator will stand and run the Staging Area. I haven't worked out the details yet, but the operator will use a CAB-1 remote and/or a set of switch pushbuttons to control switches. I had not planned on any sort of control panel for the layout, but this is the place I could make an exception.

Another feature of the Staging Area is its storage shelves. Four 10' rows of Glenn Snyder shelving have been installed on the back wall (to the extreme right of the above diagram); these are reserved (mostly) for steel-related cars. Another four 10' rows are on the back of the backdrop divider. I expect these to be used for other types of freight cars and maybe a few passenger cars. Practice will determine if the theory holds up.

The two north-south loops of track (between the openings) will be used to store whole (probably "run-through") trains. The double cross-over is capable of storing 4 large locomotives; the spurs at extreme right (top and bottom) will each hold another large locomotive. I am pretty selective about my fleet of engines and don't expect it to get much larger.

Here are some looks at the shelving. First, the shelving on the back wall. Some of the bench work for the double cross-over is also visible below it.

Now the shelving on the back of the backdrop divider.

Hope this gives you some ideas.

George

16" X 16 ' lower staging

1/2" Homosote, 3/4" Ameritech

<- nearest 4 tracks are staging.

Brad Strong made special spliced turnouts to push all switches back into the 90 degree approach to maximize yard trackage.