First of all, thanks to LaidOffSick for his inspiration and help on this project; especially his YouTube videos, and to Ron H for the work he's done on his PAs.

This is a project that I've been working on for a few weeks, and have finally been sent to be 3-D printed.

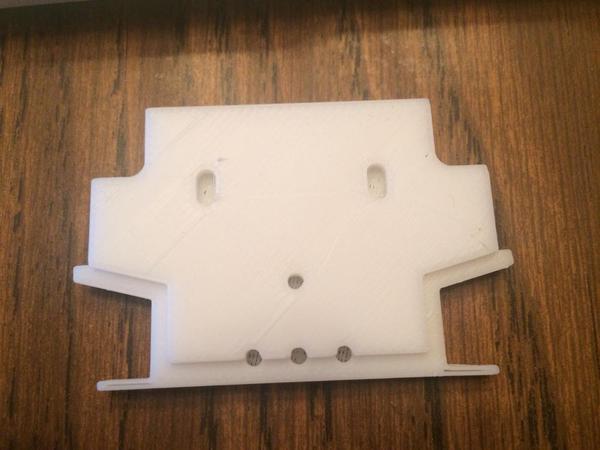

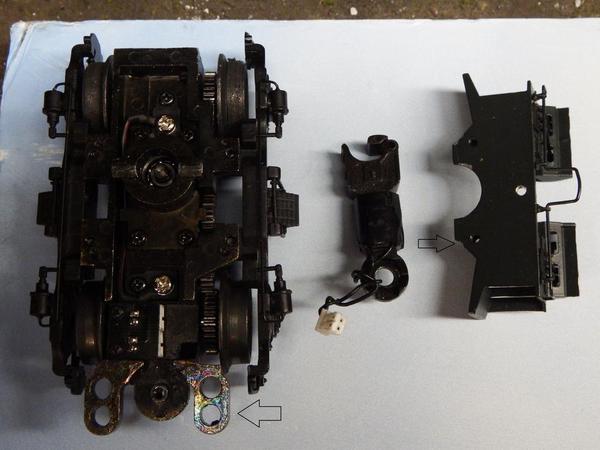

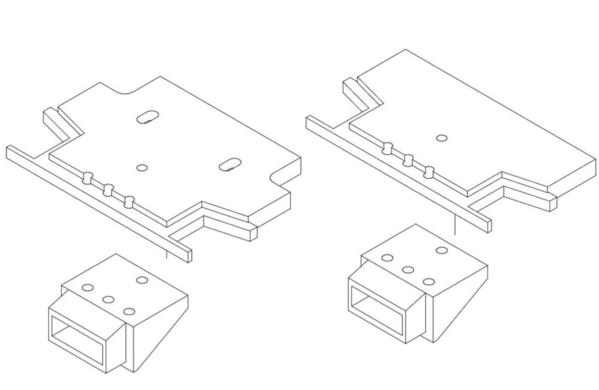

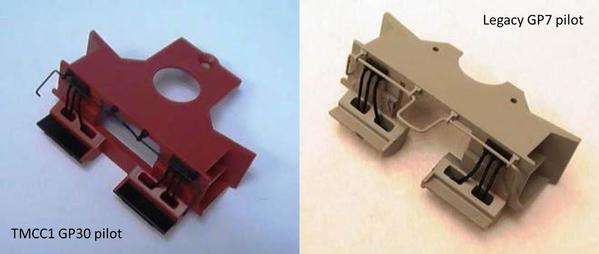

They are front and rear pilot spacers for a Lionel GP30, and pilot inserts with Kadee mounting holes to make it all one unit. You can see from the front pilot spacer that there is a slot (with countersink on the bottom side for screw head) which will affix the whole assembly to the frame. For the back one, I haven't figured that out yet, but it will probably involve drilling new holes into the frame.

They are stepped to fit up inside the body and flush against the frame.

As for the pilot filler block, it is designed specifically to fit the opening in the pilot, and have the Kadee 740-series coupler at the proper height above the railhead (0.781") and the whole assembly drops the pilot 0.010" closer to the railhead. The filler block is also designed to have the uncoupling lever right above the pin in the coupler, an the holes in the coupler block have an extra 0.001" play to allow for movement. The whole assembly, with the coupler box inserted though the block, and affixed to the bottom of the pilot (holes will need to be drilled through the factory pilot) and into the spacer, which have slightly undersized holes and is designed to use 2-56 self tapping screws.

I should have a pilot example by next week... But I can't hold my excitement, so I had to share it.

I'm not keeping this idea to myself, if you have access to your own 3-D printer, I can email you the .STL file. Don't worry, I'll be offering these as sets, as soon as the engineering is finished.

Thanks,

- Mario

PS - Once this project is finished, here's a list of future pilot spacer projects, in probable order:

- Atlas GP35s - DONE!

- MTH GP35s - See Thor's work!

- Lionel RS11s - DONE!

- Lionel Legacy GP7s - DONE!

- Lionel H16-44s - DONE!

![[Untitled]001 [Untitled]001](https://ogrforum.ogaugerr.com/fileSendAction/fcType/0/fcOid/38596415189484210/filePointer/38596415668055188/fodoid/38596415668055181/imageType/MEDIUM/inlineImage/true/%255BUntitled%255D001.jpg)

![[Untitled]001 [Untitled]001](https://ogrforum.ogaugerr.com/fileSendAction/fcType/0/fcOid/38596415189484210/filePointer/38596415668055188/fodoid/38596415668055181/imageType/SQUARE_THUMBNAIL/inlineImage/true/%5BUntitled%5D001.jpg)