I reinstalled the scout motor in the Lionel 1110 locomotive, and got it running probably as good as it's going to get for now. This is what it looks like:

I put it on the track and did some testing.

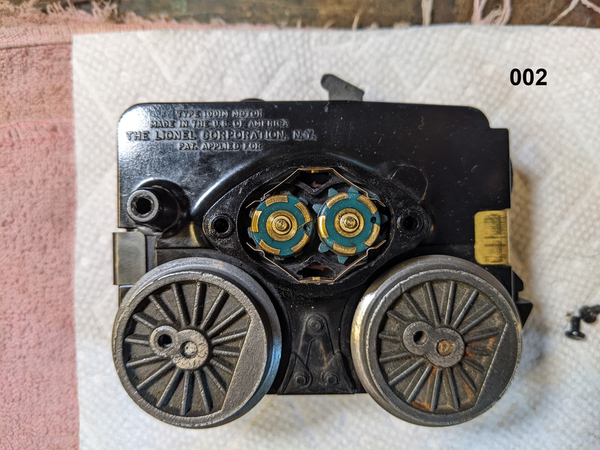

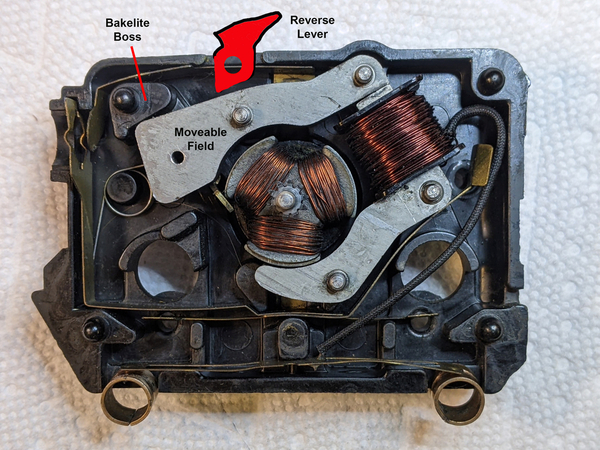

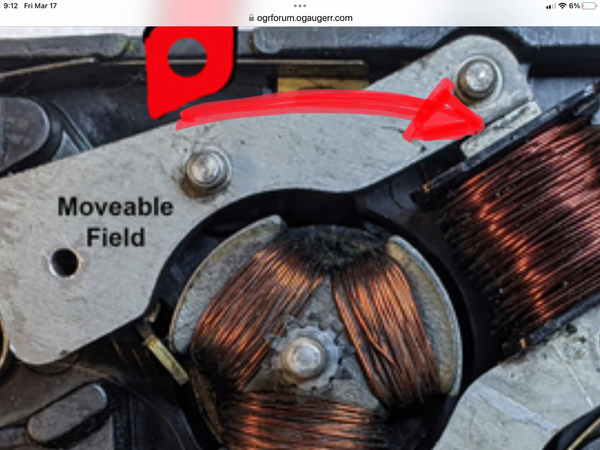

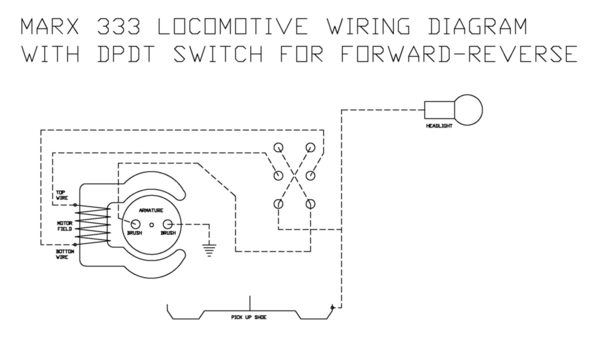

So, first let me describe some salient mechanical/electrical features of the locomotive. It has a diecast body and it weighs 1 lb 9.2 oz. The locomotive has the plastic-bodied scout motor. The gear ratio is 7.88 to 1. I was able to determine this by opening up the plastic body, counting the gear teeth, and doing the math.

I bench tested the locomotive at 13.5 VAC output from the transformer and measured the drive wheel rotational speed using a Cen Tech digital photo sensor tachometer. The drive wheel rpm was in the range of 505 - 600 rpm. So, for purposes of my calculations I used an average value of 550 rpm. Since I don't have the ability to directly measure the rotational speed of the motor, and since the Scout motor has a gear ratio of 7.88 to 1, I calculated a motor rpm equal to 4,336.

Now let me describe the test rig. I have a loop of 0-31 gauge tubular track, and the total center-rail length is 13.4434'. I have a 275 watt Lionel ZW transformer, and I have power applied in two separate equidistant points along the line. I have a digital multimeter to monitor the track voltage. I used a lock-on to connect the red and black probes. I have an inexpensive clamp-style amp meter to monitor the amperage from the hot wire between the transformer and the track. I also have a 10 turn loop in this hot wire to improve the accuracy of the amp readings. For the time trial, I used the stopwatch feature of my Android phone, and timed the train over 5 laps. I tested just the locomotive at discrete 1 volt increments from 7 to 11 volts AC. Outside of this band, the locomotive either would not move or would move so fast I was afraid that I'd derail and damage it. I then connected a tender, three freight cars, and a caboose and repeated the time trials at 9 through 13 VAC. Again, the train would not move at less than 9 VAC, and would run too fast beyond 13 VAC. Below is the velocity calculations and amp draw:

Without Cars

| TRACK VOLTAGE | Elapsed Time MIN | Speed FPM | Motor RPM | Speed MPH | Scale MPH | Amp Readings | Power Watts | HP |

| 7 | 1.1833 | 56.8031 | 1368.5 | 0.65 | 31.0 | 1.15 | 8.05 | 0.0108 |

| 8 | 0.7512 | 89.4835 | 2155.8 | 1.02 | 48.8 | 1.2 | 9.6 | 0.0129 |

| 9 | 0.5938 | 113.1917 | 2727.0 | 1.29 | 61.7 | 1.25 | 11.25 | 0.0151 |

| 10 | 0.5308 | 126.6254 | 3050.7 | 1.44 | 69.1 | 1.3 | 13 | 0.0174 |

| 11 | 0.4587 | 146.5487 | 3530.6 | 1.67 | 79.9 | 1.35 | 14.85 | 0.0199 |

With 5 Cars

| TRACK VOLTAGE | Elapsed Time MIN | Speed FPM | Motor RPM | Speed MPH | Scale MPH | Amp Readings | Power Watts | HP |

| 9 | 1.2897 | 52.1197 | 1255.7 | 0.59 | 28.4 | 1.3 | 11.7 | 0.0157 |

| 10 | 0.8788 | 76.4844 | 1842.7 | 0.87 | 41.7 | 1.35 | 13.5 | 0.0181 |

| 11 | 0.6807 | 98.7517 | 2379.1 | 1.12 | 53.9 | 1.4 | 15.4 | 0.0207 |

| 12 | 0.5868 | 114.5419 | 2759.5 | 1.30 | 62.5 | 1.5 | 18 | 0.0241 |

| 13 | 0.5142 | 130.7300 | 3149.5 | 1.49 | 71.3 | 1.6 | 20.8 | 0.0279 |

Note that at 9 VAC, the locomotive alone was running at 61.7 MPH (scale), drawing 1.25 amps, 11.25 watts. When I attached the cars to the locomotive and ran it at 9 VAC, it slowed down to 28.4 MPH (scale) drawing 1.3 amps and 11.7 watts. One thing I should point out is that my amp readings would usually spike when the locomotive was on the curve sections, so my amp readings are sort of a composite. I also bench tested the locomotive at 9 VAC, and it was drawing 0.9 amps and 8.1 watts. So, I prepared a pie chart showing the power profile at 9 VAC. As you can see, the majority of the power was consumed by mechanical & electrical inefficiencies and just moving the weight of the locomotive. Only a small fraction of the total power was consumed by pulling the cars.

Here is a short video clip of the Lionel 1110 pulling five cars with an applied voltage of 9 VAC.

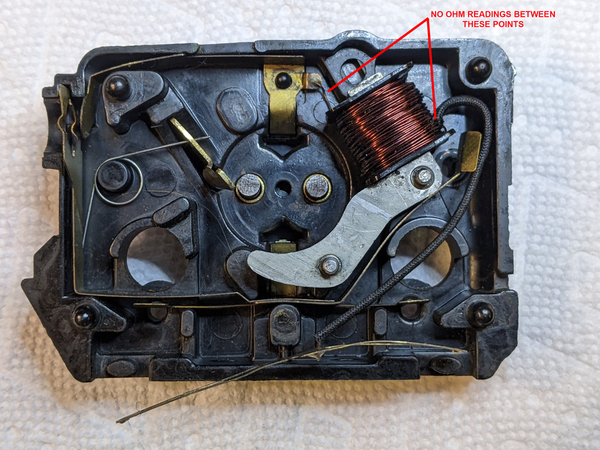

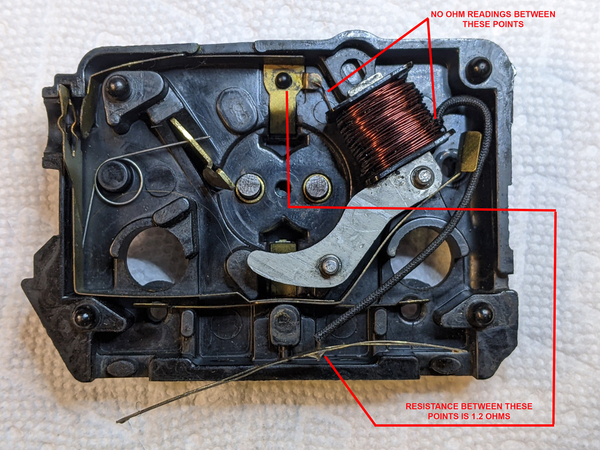

The operation is noisy and somewhat quirky - although it is not slugging as bad as it was when I originally made this posting to the forum. Chuck Sartor and Pat Norcross recognized right away that this Scout motor needed more lubrication when they saw my original video posting. The first time I opened up the motor, most of the moving parts were packed with thick grease - which took some time to clean out. There was still residual grease in the plastic bushings - but apparently, that still wasn't enough lubrication. So I added a few drops of light oil to all of the moving parts. That got rid of most of the slugging. The bakelite motor housing had some cracked sections that I repaired with JB Weld. The e-unit works, but not consistently, and sometimes the locomotive stalls when I try to start it from a dead stop. Usually I give it a little push and then restart it. So, I still have some problems to work out. The locomotive was given to me by Pat Norcross of Harmon Yards - thanks so much Pat. This was a fun project.