Howdy all,

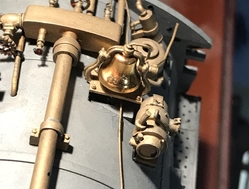

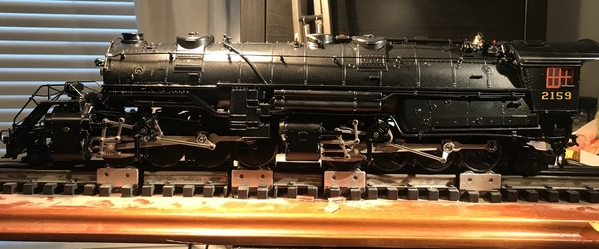

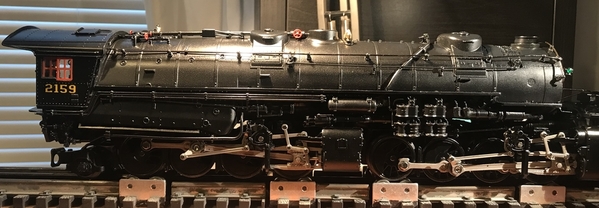

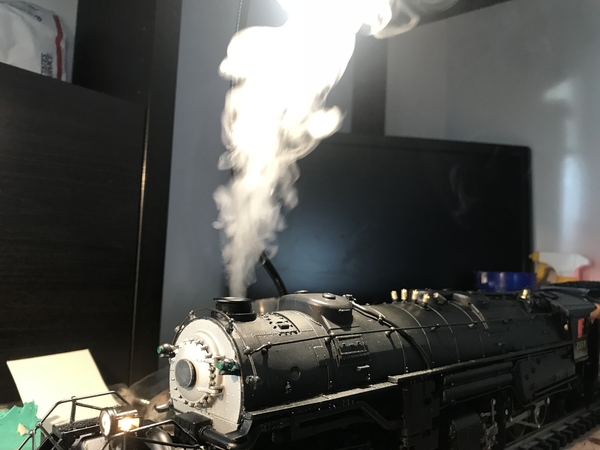

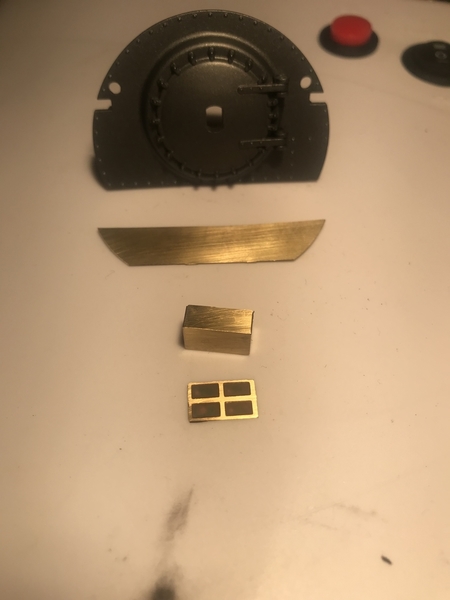

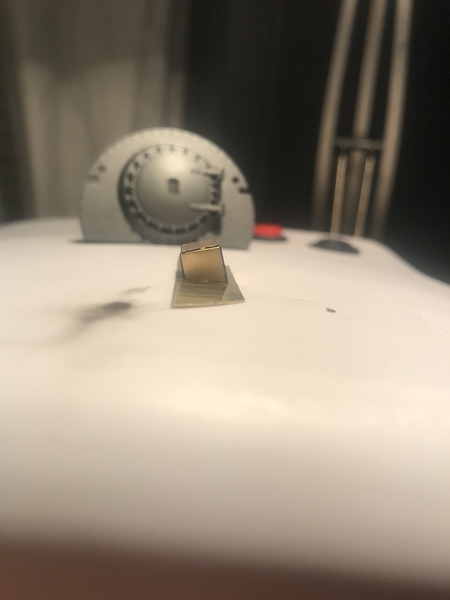

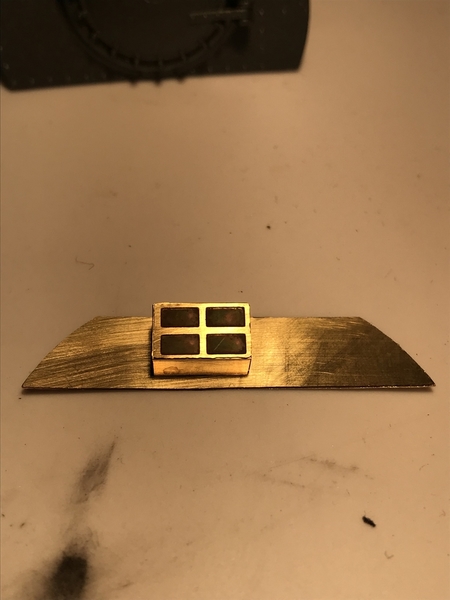

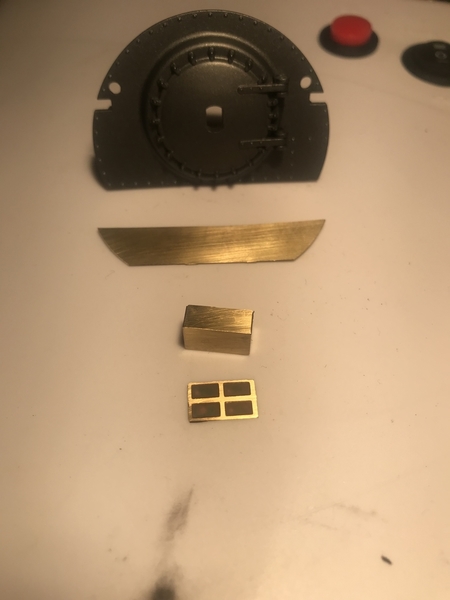

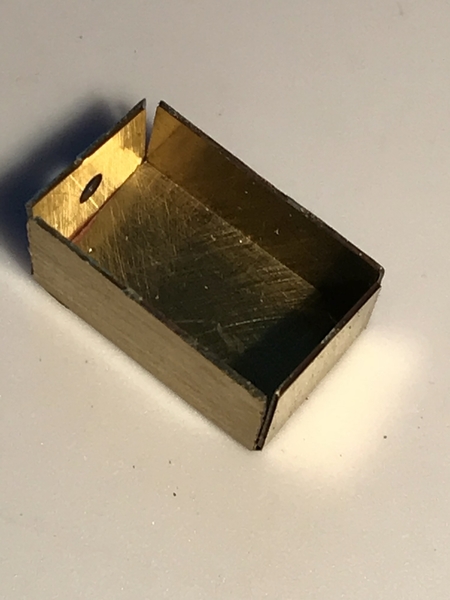

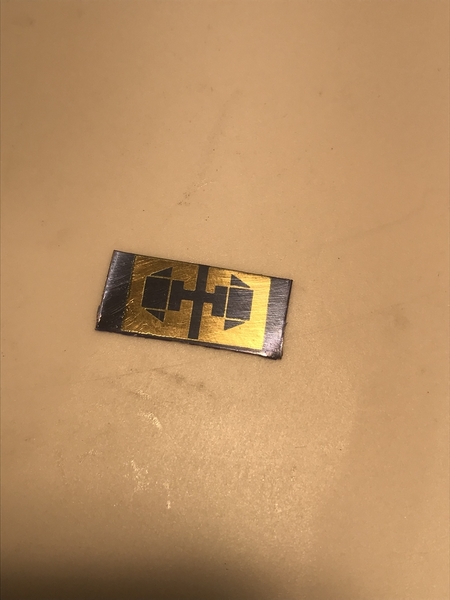

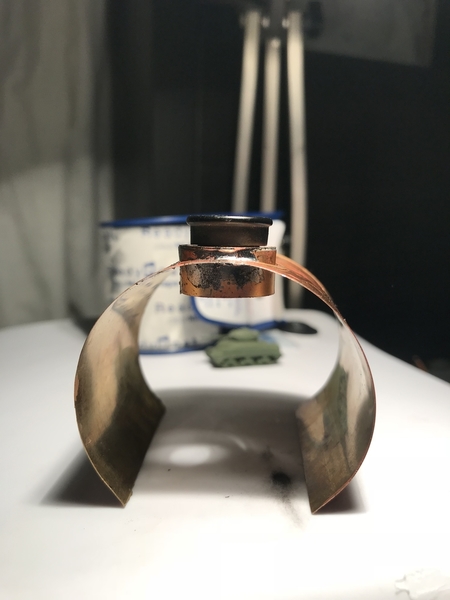

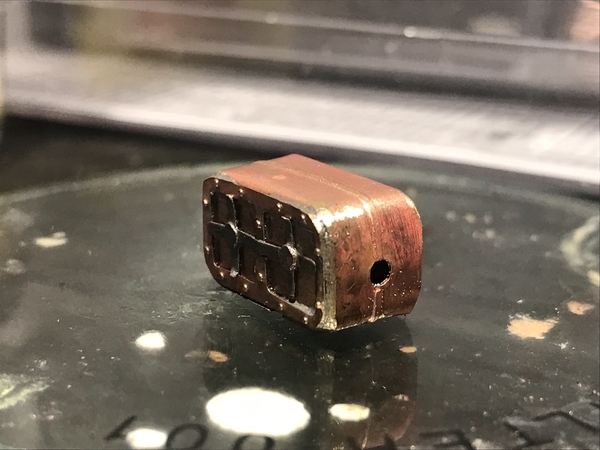

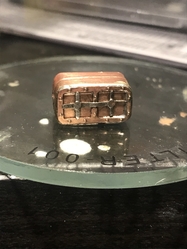

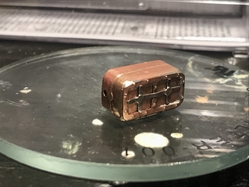

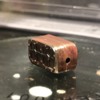

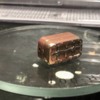

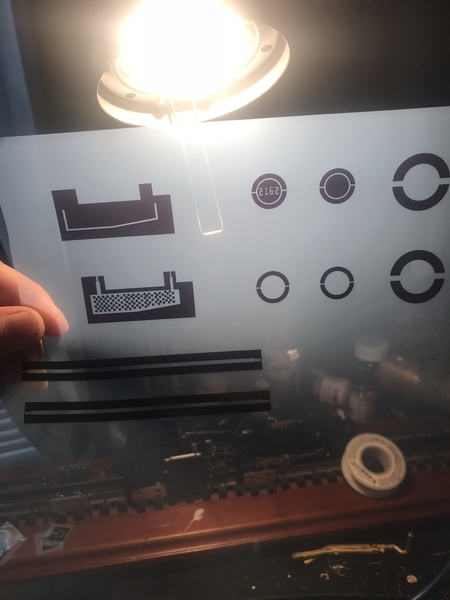

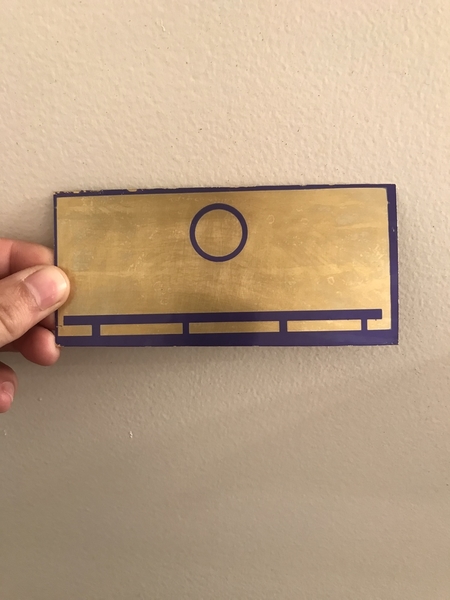

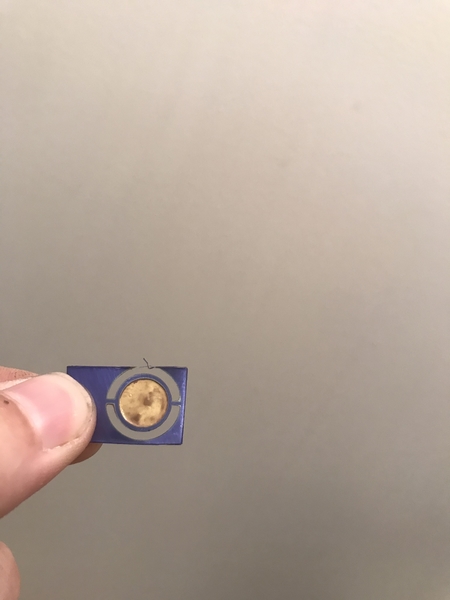

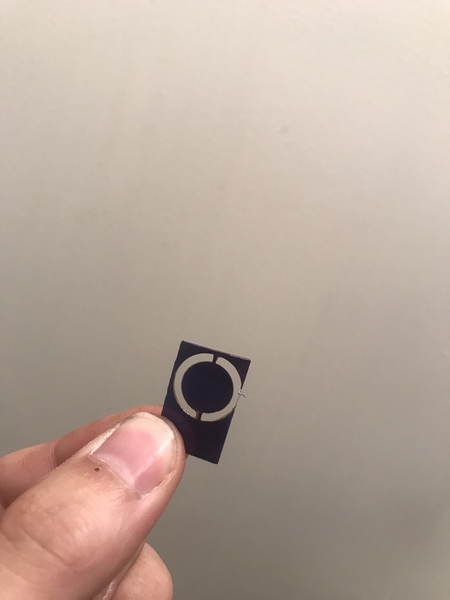

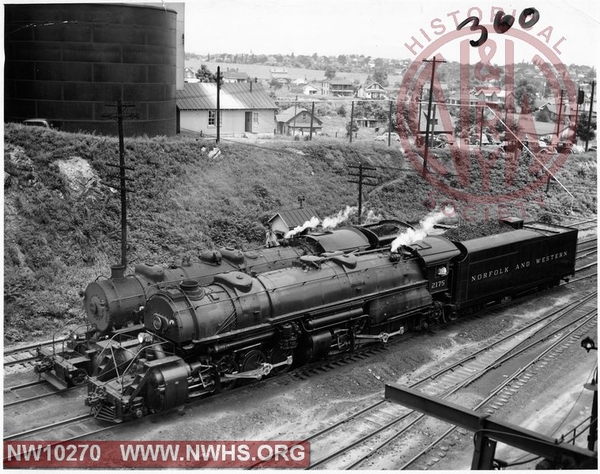

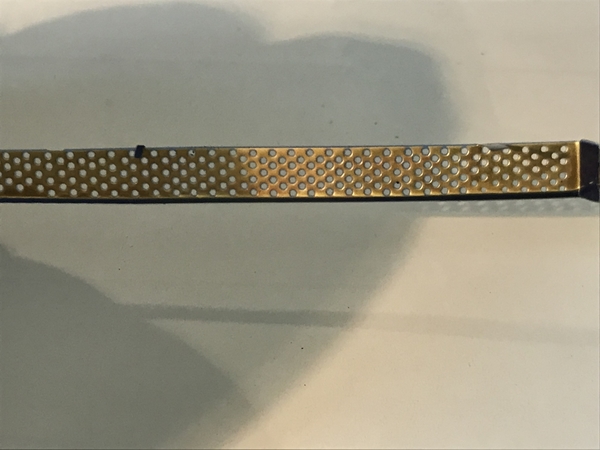

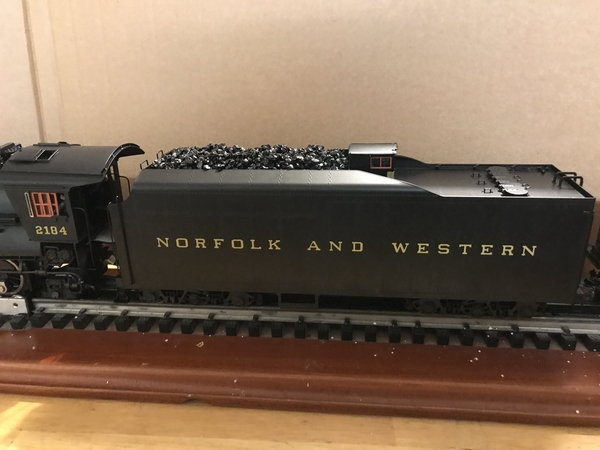

This will be the post where I add updates to my conversion. I will be photo etching and scratch building a few parts. A few parts are in the mail. I will roll a new unlagged smokebox out of brass and solder the detail pieces on. The running board will need to be stepped down over the Worthington feed supply. Kohs made a y6a with lagged smokebox but I can't find any information to back this up. Maybe Hot Water or Big Jim would know?

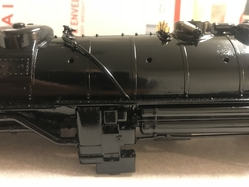

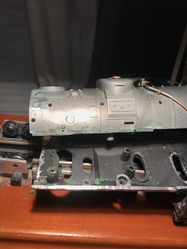

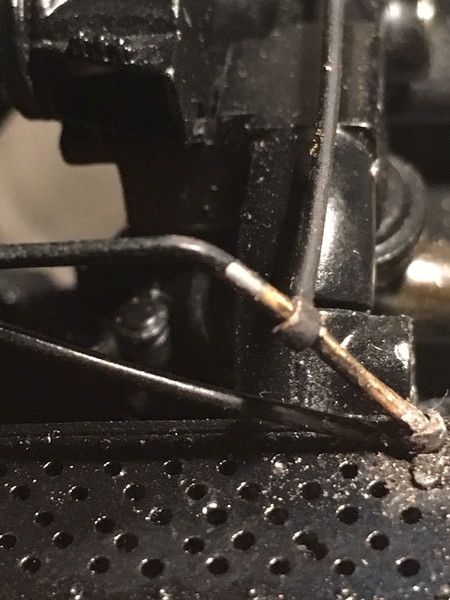

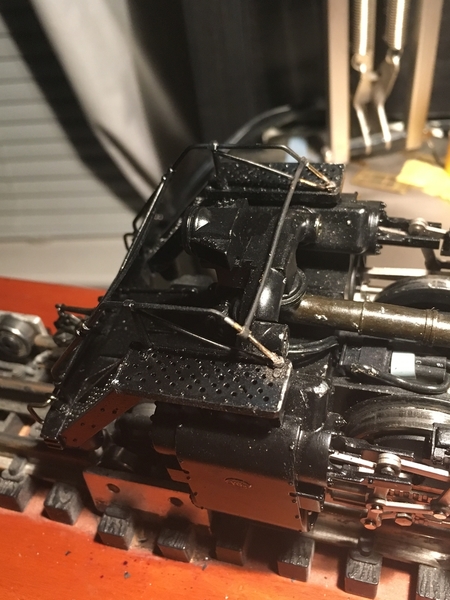

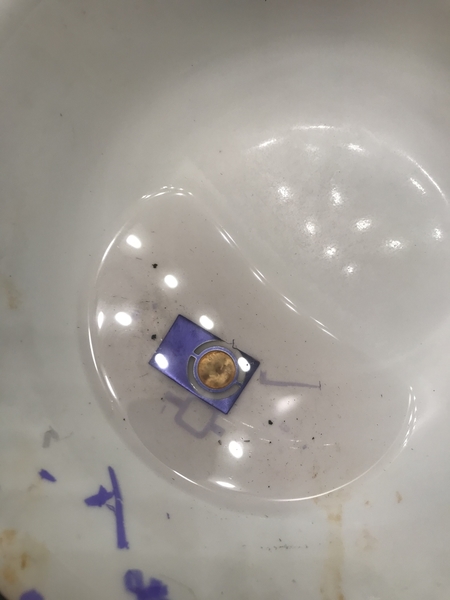

To start with, the entire engine needed to be disassembled down to an empty boiler. A few detail pieces removed and more to be added. I started with removing the air pump from the fireman's side to be added to the engineers side. Pics to follow. The boiler, if using a lagged box will need to be shortened and new mounting tabs made. If using the unlagged, like the 2156 represents, the smokebox will need to be cutoff and a new tube rolled and soldered to the existing boiler.

Lets have fun